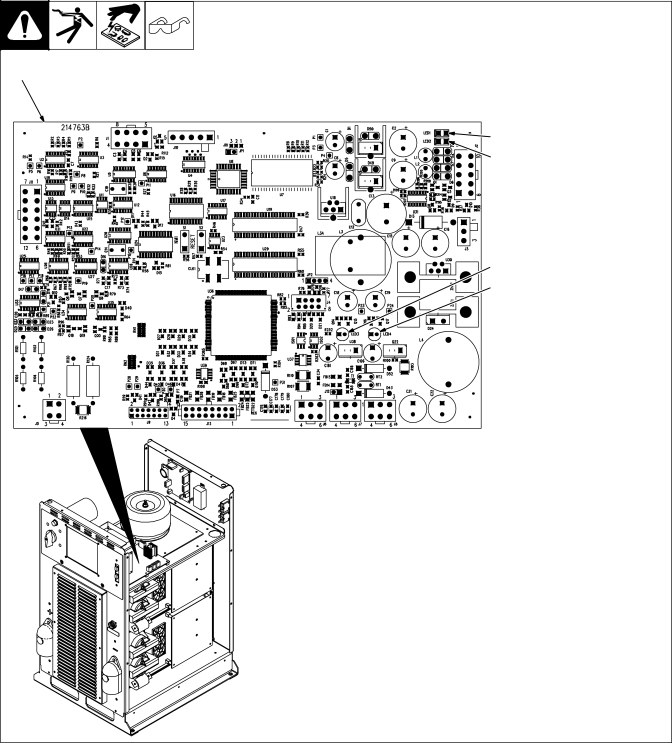

9-2. Process Control Module PC4 Diagnostic LED’s

| 1 Process Control Module PC4 |

| Diagnostic LED’s are visible inside unit, |

| located on PC4 mounted on the top tray. |

| Refer to Section |

1 | diagnostic LED’s. |

| |

| Reinstall cover after checking diagnostic |

| LED’s. |

| LED1 |

| LED2 |

LED3

LED4

216

9-3. Diagnostic LED’s On Process Control Module PC4

LED | Status | Diagnosis |

|

|

|

1 | On | Indicates −25 volts dc is present on process control module PC4 |

|

|

|

| Off | Indicates −25 volts dc is not present on process control module PC4 |

|

|

|

2 | On | Indicates +25 volts dc is present on process control module PC4 |

|

|

|

| Off | Indicates +25 volts dc is not present on process control module PC4 |

|

|

|

3,4 | On | See Network Status Table in Section |

|

|

|

| Off | See Network Status Table in Section |

|

|

|