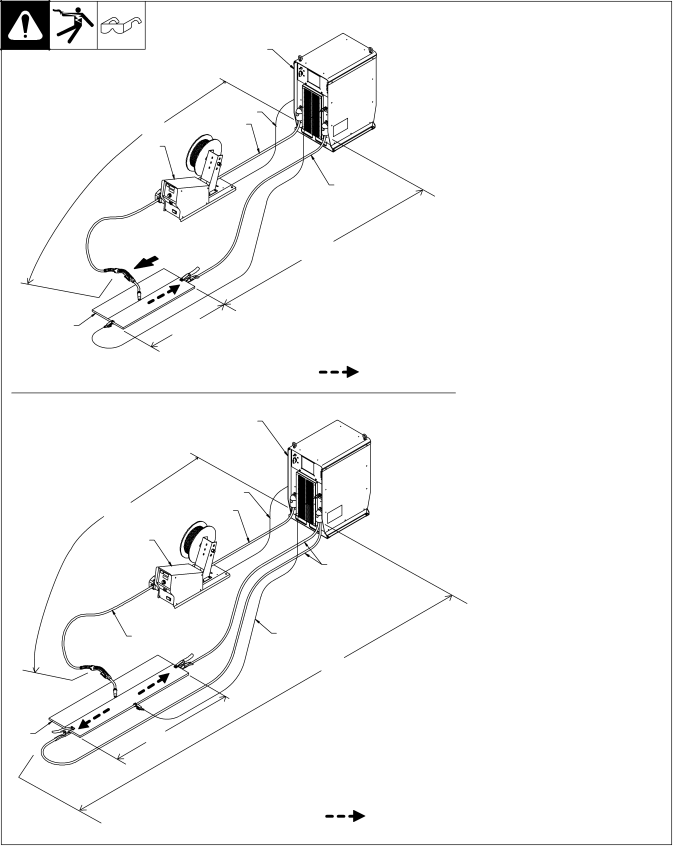

5-2. Welding Circuit

. Minimizing the welding circuit loop can prevent extreme voltage drops that produce poor welding characteristics.

1

Standard Welding Circuit

3

ECL2

6

4

![]() 5

5

Gun

TravelWCL

7 | WL |

Current Flow Path

Large Weld Structure

1

3

ECL2

6

4

1Welding Power Source

2Electrode Cable

3Feeder Cable

4Work Cable

5Voltage Sensing Lead

6Wire Feeder

7Workpiece

In pulse welding applications using inverter power sources, cable resistance can result in less than satisfactory performance. In most cases, a welding circuit length of 50 ft (15 m) or less will provide satisfactory performance with a standard welding circuit connection.

The length of a welding circuit is determined as follows:

Welding Circuit = Electrode Cable Length (ECL) + Work Cable Length (WCL) + Workpiece Length (WL)

See Section

Variations in welding processes and welding circuit resistance can affect apparent voltage at the welding arc. Voltage sensing can improve welding performance by providing accurate feedback to the welding power source.

It is important to connect the voltage sensing lead as near to the weld as possible, but not in the return current path.

2 | 5 |

WCL

7WL

Current Flow Path

Ref. 804