Additional Safety Instructions for Grinders

1.EYE PROTECTION. Grinding causes small particles to become airborne at a high rate of speed. ALWAYS wear safety glasses when using this machine.

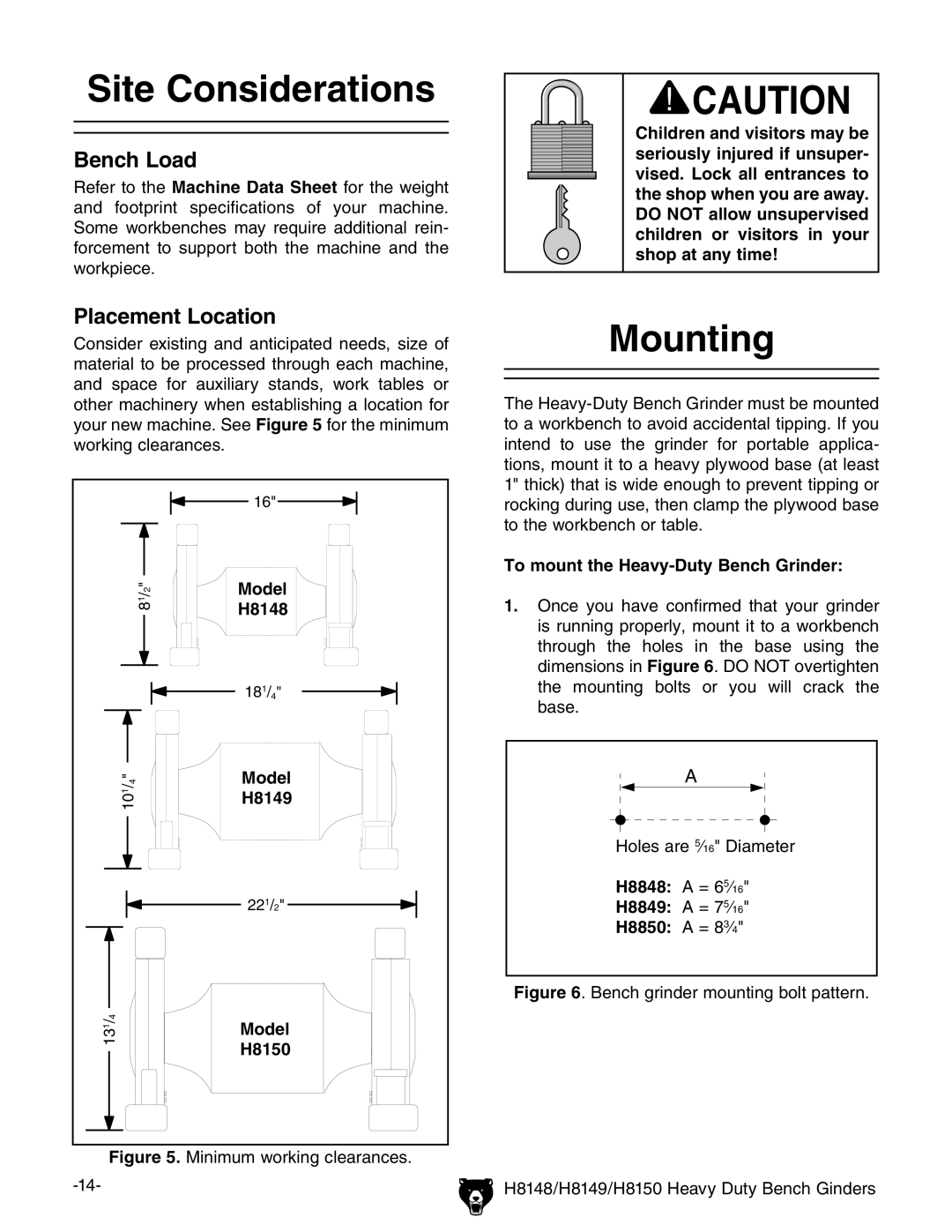

2.MOUNTING TO BENCH/STAND. An unse- cured grinder may become dangerously out of control during operation. Make sure grinder is FIRMLY secured to a bench/ stand before use.

3.WHEEL SPEED RATING. Wheels oper- ated at a faster speed than rated for may break or fly apart. Before mounting a new wheel, be sure the wheel RPM rating is equal to or higher than the speed of the grinder.

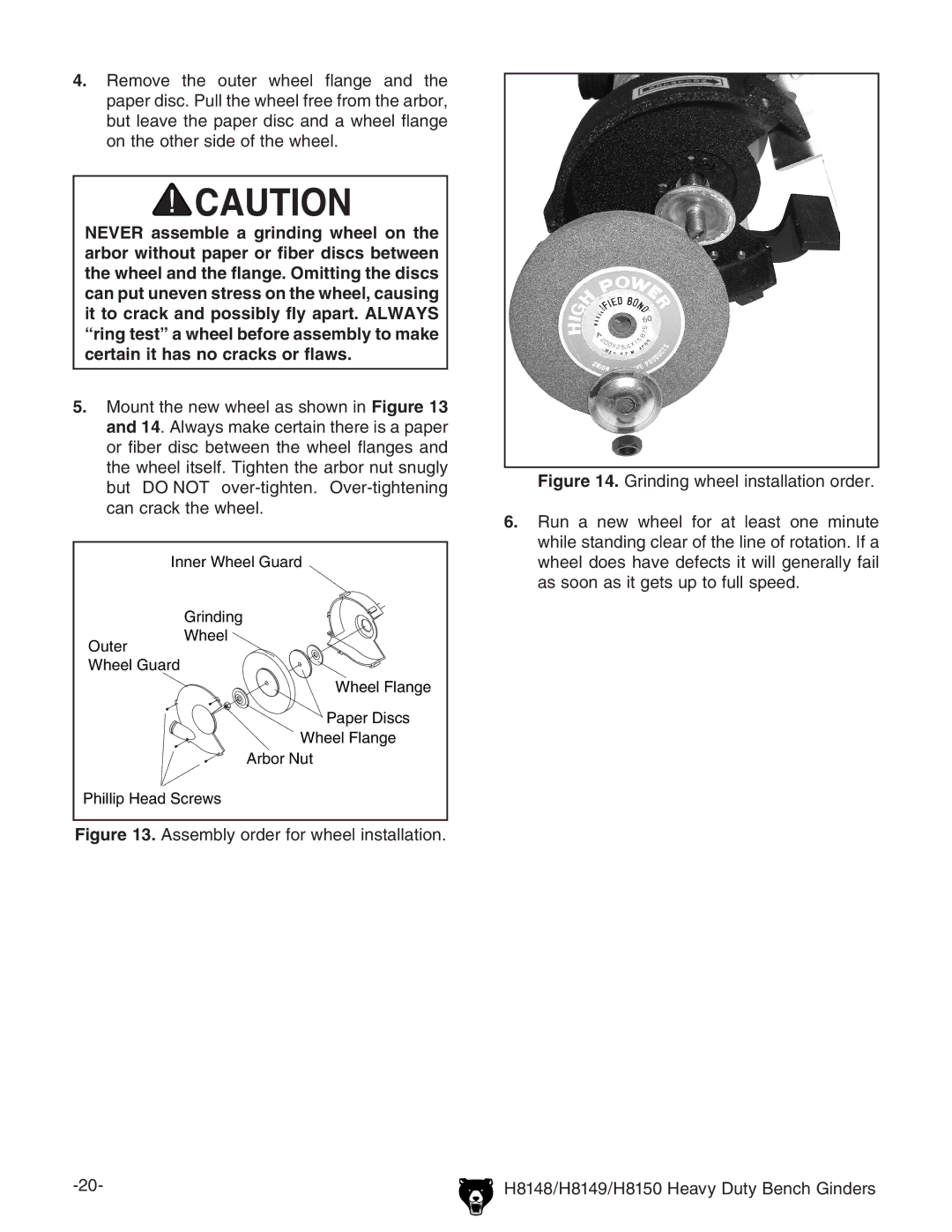

4.WHEEL FLANGES. Only use the flanges included with the grinder when mounting wheels. Other flanges may not properly secure the wheel and cause an accident.

5.RING TEST. Perform a “ring test” on grind- ing wheels before installation to ensure that they are safe to use. A wheel that does not pass the ring test may break or fly apart during operation.

6.STARTING GRINDER. If a wheel IS dam- aged, it will usually fly apart shortly after

7.LUNG PROTECTION. Grinding produces hazardous dust, which may cause long- term respiratory problems if breathed. Always wear a NIOSH approved dust mask or respirator when grinding.

8.SIDE GRINDING. Grinding on the side of wheels can cause them to break and fly

9.TOP GRINDING. Grinding on the top of wheels greatly increases the risk of workpiece kickback. Always grind on the downward part of the wheel.

10.HAND/WHEEL CONTACT. Grinding wheels have the capability of removing a lot of skin fast. Keep a firm grip on the workpiece and position your hands a safe distance away when grinding. Avoid wear- ing gloves as they may get caught in the grinding wheel and cause even more seri- ous entanglement injuries.

11.TOOL REST POSITION. If the tool rest is too far away from the wheel, the workpiece may be pulled down, causing loss of con- trol and pulling your hand into the grinding wheel. Keep the tool rest within 1⁄8" from the wheel when operating.

Like all machinery there is potential danger when operating this machine. Accidents are frequently caused by lack of familiarity or failure to pay attention. Use this machine with respect and caution to lessen the pos- sibility of operator injury. If normal safety precautions are overlooked or ignored, seri- ous personal injury may occur.

H8148/H8149/H8150 Heavy Duty Bench Grinder

No list of safety guidelines can be complete. Every shop environment is different. Always consider safety first, as it applies to your individual working conditions. Use this and other machinery with caution and respect. Failure to do so could result in serious per- sonal injury, damage to equipment, or poor work results.