Site Considerations

Bench Load

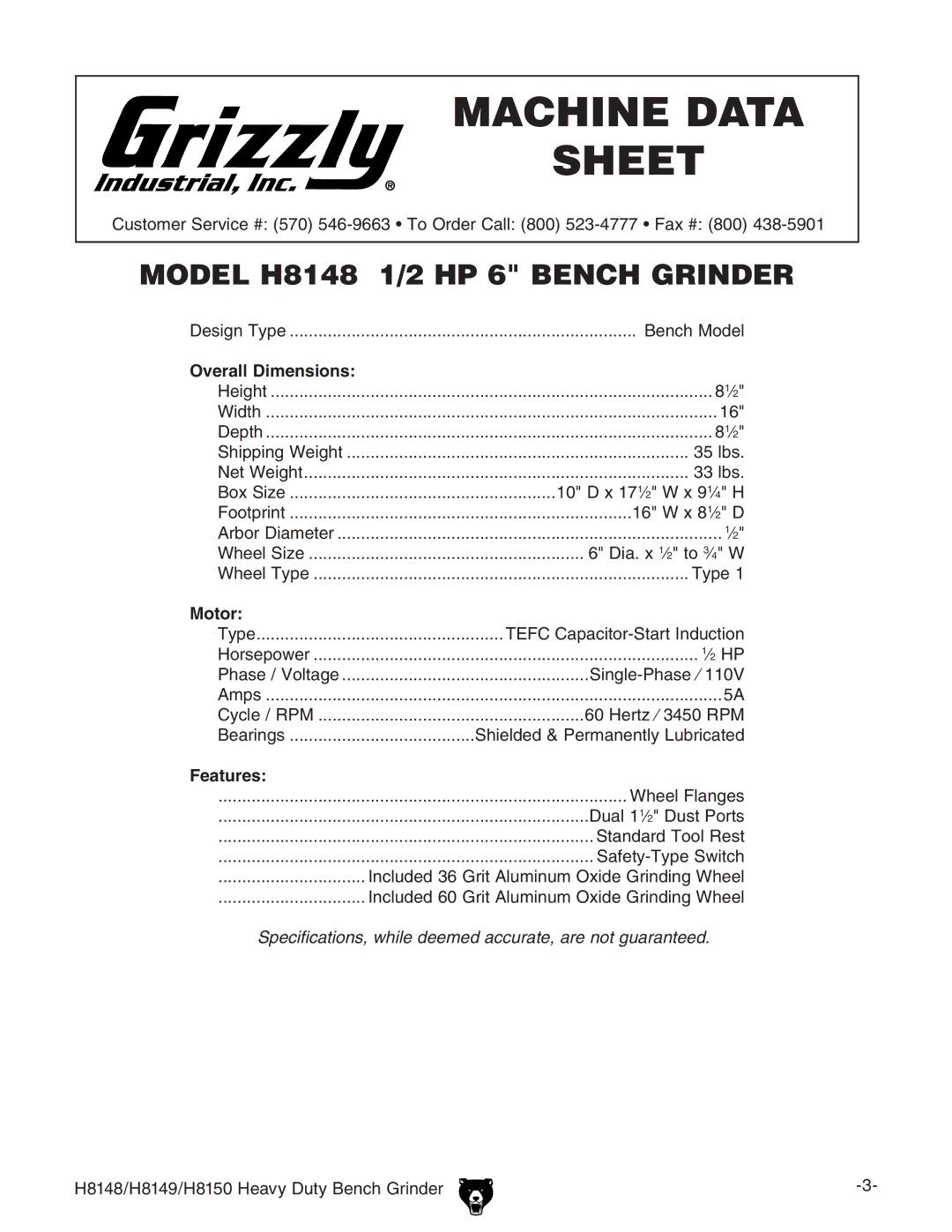

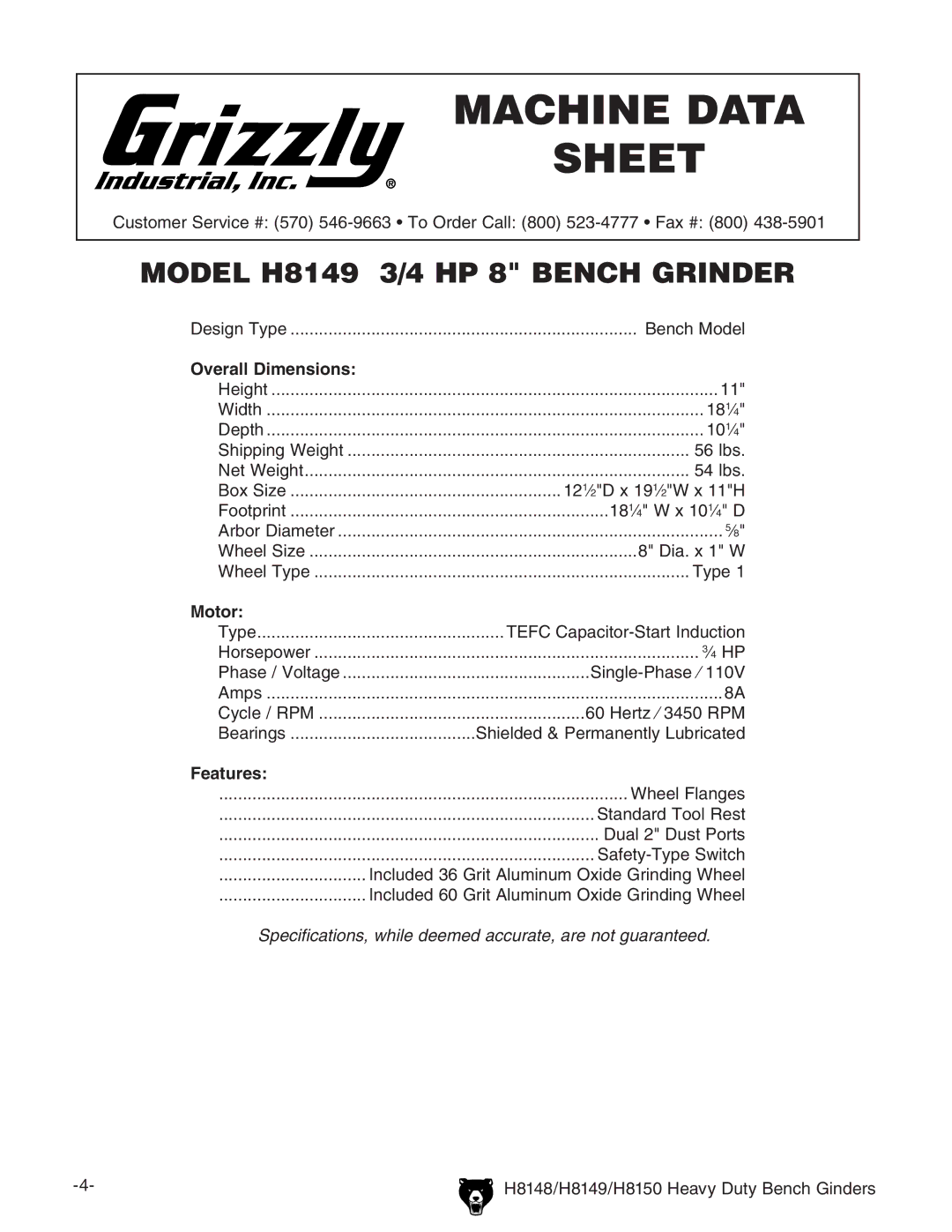

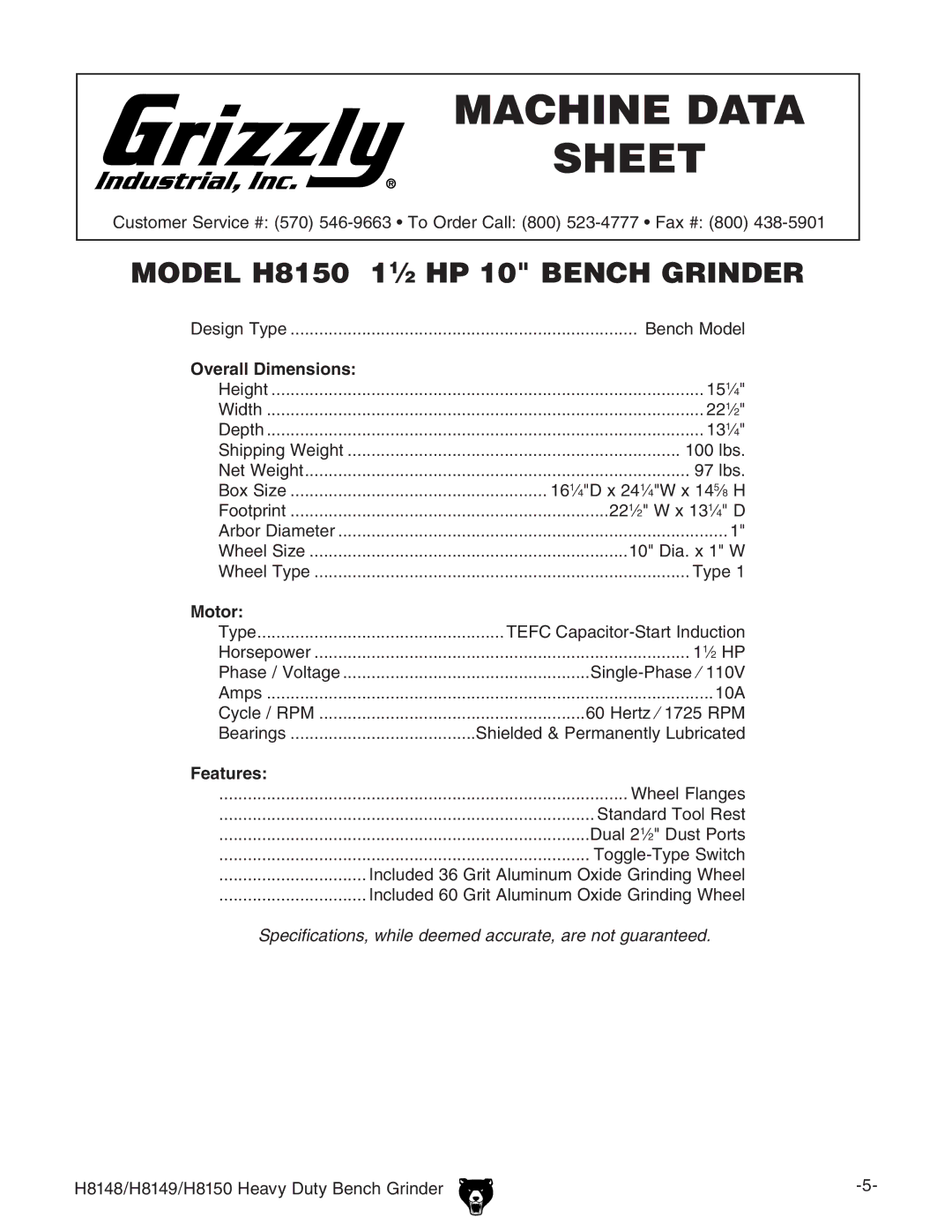

Refer to the Machine Data Sheet for the weight and footprint specifications of your machine. Some workbenches may require additional rein- forcement to support both the machine and the workpiece.

Placement Location

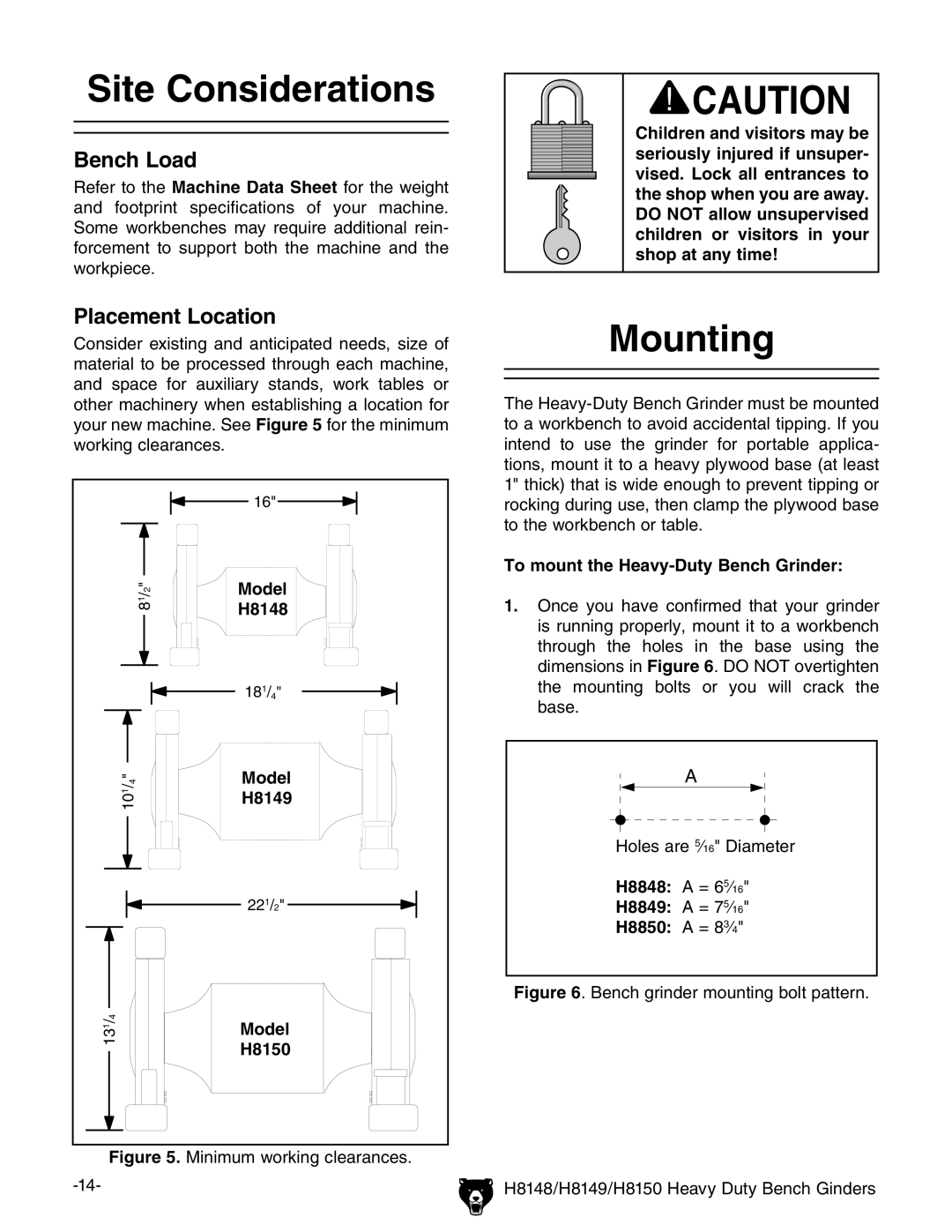

Consider existing and anticipated needs, size of material to be processed through each machine, and space for auxiliary stands, work tables or other machinery when establishing a location for your new machine. See Figure 5 for the minimum working clearances.

���

�� | Model |

��� | H8148 |

|

������

� | Model | |

� |

| |

�� | H8149 | |

�� | ||

|

������

��� | Model | |

�� | ||

H8150 | ||

|

Figure 5. Minimum working clearances.

Children and visitors may be seriously injured if unsuper- vised. Lock all entrances to the shop when you are away. DO NOT allow unsupervised children or visitors in your shop at any time!

Mounting

The

To mount the Heavy-Duty Bench Grinder:

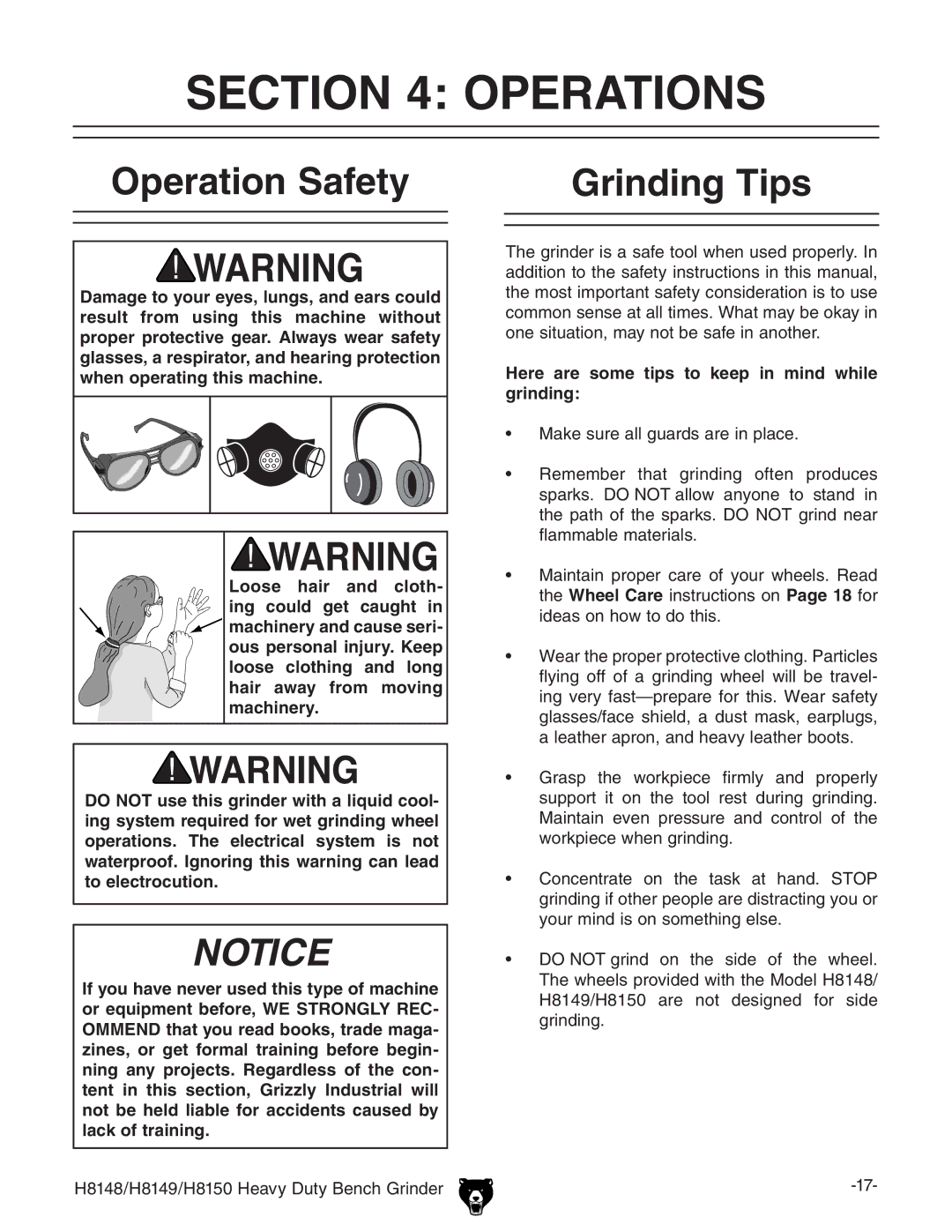

1.Once you have confirmed that your grinder is running properly, mount it to a workbench through the holes in the base using the dimensions in Figure 6. DO NOT overtighten the mounting bolts or you will crack the base.

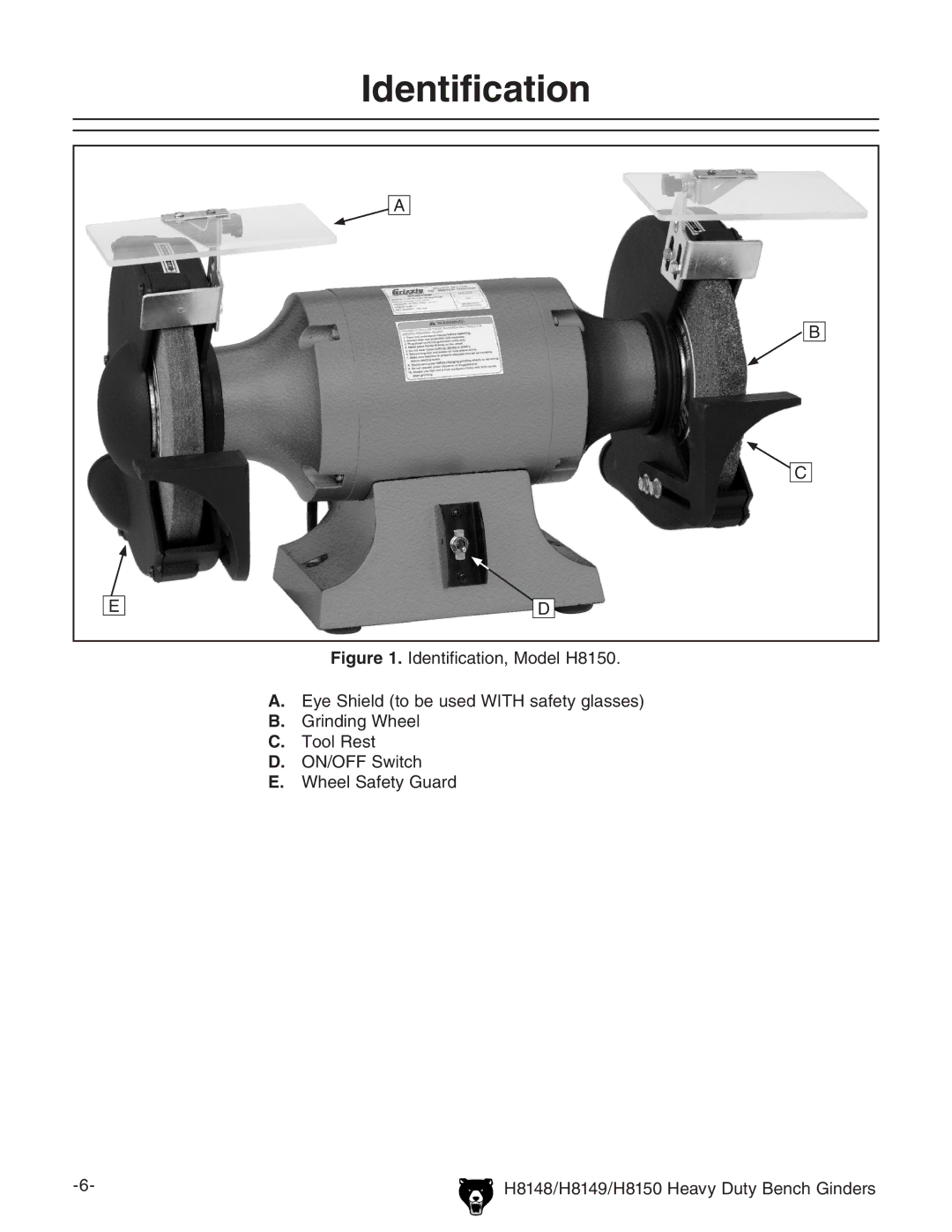

A

Holes are 5⁄16" Diameter