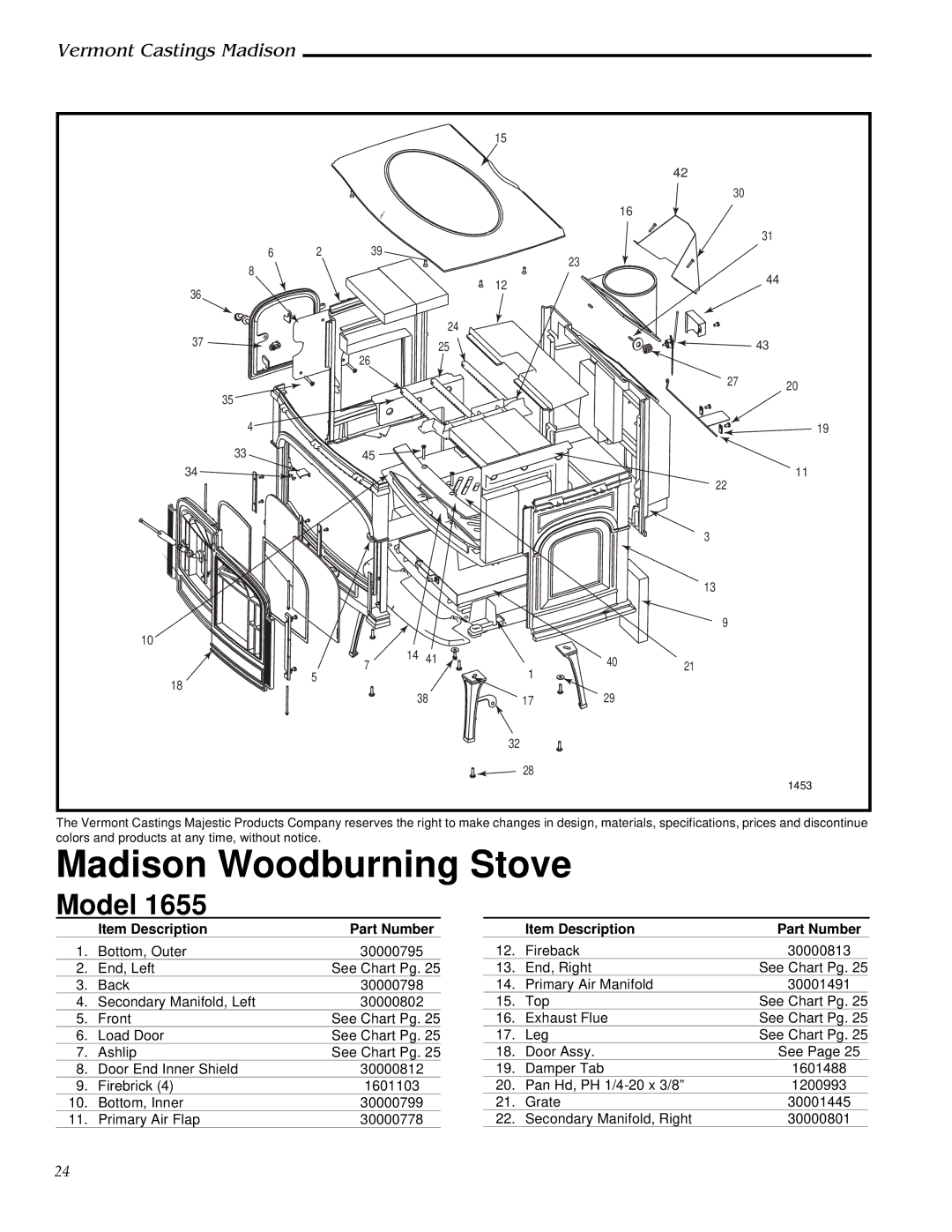

1655, 1656, 1657, 1658, 1659 specifications

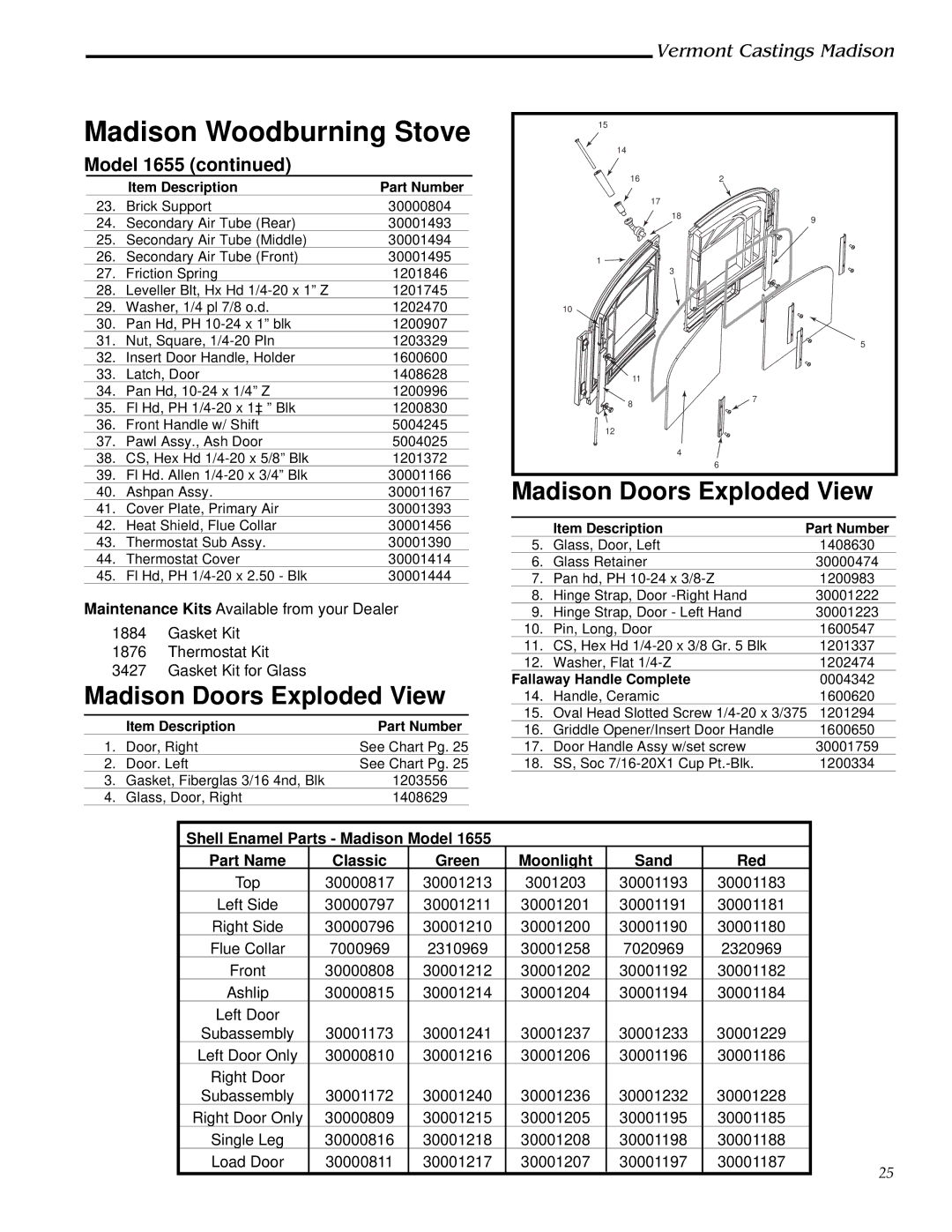

Vermont Castings has long been synonymous with high-quality cast iron stoves and fireplaces, and models 1655, 1656, 1657, 1658, and 1659 are prime examples of the craftsmanship and innovation that define the brand. Each model showcases a unique combination of features, technologies, and characteristics designed to enhance the home heating experience.The Vermont Castings 1655, also known as the Defiant wood stove, is revered for its exceptional heating efficiency and classic design. With a large firebox, it can accommodate logs up to 18 inches long, making it an ideal choice for long, uninterrupted burns. Its dual door design not only provides ease of access but also enhances the aesthetic appeal with its elegantly arched glass. The stoves feature the brand's innovative Catalyst technology, which ensures complete combustion of gases, reducing emissions while maximizing heat output.

The 1656 model, known as the Intrepid II, is compact yet powerful. It is perfect for smaller spaces, providing significant heat without compromise. With its traditional styling and hand-crafted quality, it stands as a testament to Vermont Castings' commitment to aesthetics. The stove incorporates a secondary combustion system, which enhances efficiency by reburning flue gases, ensuring a cleaner burning process.

The 1657 model, also recognized as the Vigilant, incorporates radiant and convective heating, which is perfect for larger rooms. This model is equipped with advanced clean-burning technology, facilitating a longer burn time and reducing the frequency of reloads. The stovetop is designed to maintain heat, allowing for cooking or warming food, illustrating its versatility.

In contrast, the 1658 model, known as the Resolute, features an elegant yet rugged design that complements various interiors. Its air-wash system keeps the glass door clean, providing an unobstructed view of the flames. The Resolute is designed for easy operation, with an adjustable damper that tailors airflow, further optimizing efficiency according to user preferences.

Finally, the 1659, or the Encore model, stands out with its revolutionary two-in-one design that allows for top or front loading. This model is known for its exceptional heat retention and long burn times, catering to homeowners who value convenience and performance. Its eco-friendly features include reduced emissions and high-efficiency ratings that meet modern environmental standards.

In summary, Vermont Castings' 1655, 1656, 1657, 1658, and 1659 models offer an array of features that prioritize efficiency, performance, and style. From their unique combustion technologies to their stunning craftsmanship, these stoves represent some of the best options in the market for effective home heating solutions. Each model is a testament to Vermont Castings' enduring legacy of quality and innovation in the world of wood-burning appliances.