4.Once installed, adjust belts as shown in “Pre‑Starting Checks.”

5.Shaft bearings can be classified in two groups: relubricating and

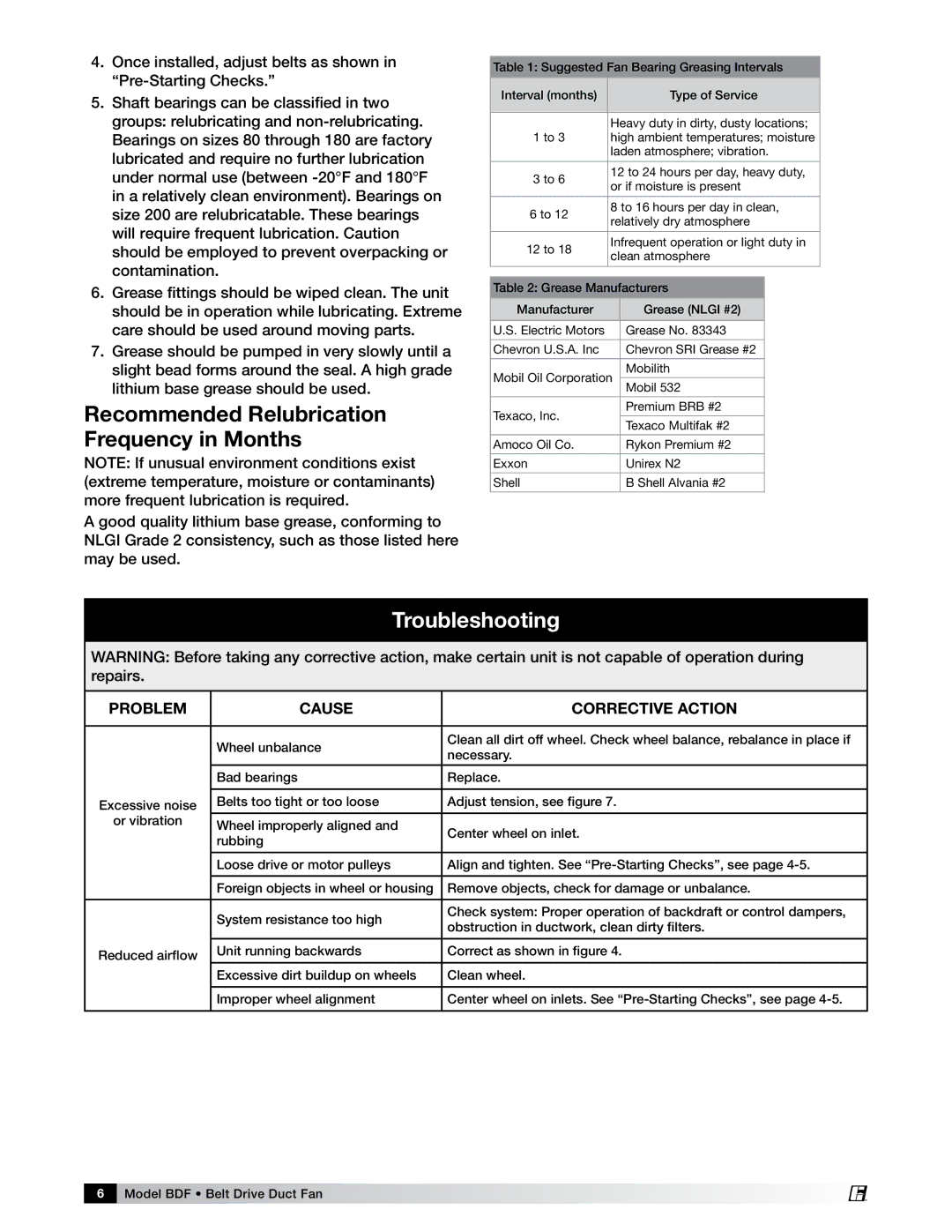

Table 1: Suggested Fan Bearing Greasing Intervals

Interval (months) | Type of Service | |

|

| |

| Heavy duty in dirty, dusty locations; | |

1 to 3 | high ambient temperatures; moisture | |

| laden atmosphere; vibration. | |

|

| |

3 to 6 | 12 to 24 hours per day, heavy duty, | |

or if moisture is present | ||

| ||

|

| |

6 to 12 | 8 to 16 hours per day in clean, | |

relatively dry atmosphere | ||

| ||

|

| |

12 to 18 | Infrequent operation or light duty in | |

clean atmosphere | ||

| ||

|

|

6.Grease fittings should be wiped clean. The unit should be in operation while lubricating. Extreme care should be used around moving parts.

7.Grease should be pumped in very slowly until a slight bead forms around the seal. A high grade lithium base grease should be used.

Recommended Relubrication Frequency in Months

NOTE: If unusual environment conditions exist (extreme temperature, moisture or contaminants) more frequent lubrication is required.

A good quality lithium base grease, conforming to NLGI Grade 2 consistency, such as those listed here may be used.

Table 2: Grease Manufacturers

Manufacturer | Grease (NLGI #2) | |

|

| |

U.S. Electric Motors | Grease No. 83343 | |

|

| |

Chevron U.S.A. Inc | Chevron SRI Grease #2 | |

|

| |

Mobil Oil Corporation | Mobilith | |

Mobil 532 | ||

| ||

|

| |

Texaco, Inc. | Premium BRB #2 | |

| ||

Texaco Multifak #2 | ||

| ||

Amoco Oil Co. | Rykon Premium #2 | |

|

| |

Exxon | Unirex N2 | |

|

| |

Shell | B Shell Alvania #2 |

Troubleshooting

WARNING: Before taking any corrective action, make certain unit is not capable of operation during repairs.

PROBLEM | CAUSE | CORRECTIVE ACTION |

|

|

|

| Wheel unbalance | Clean all dirt off wheel. Check wheel balance, rebalance in place if |

| necessary. | |

|

| |

|

|

|

| Bad bearings | Replace. |

|

|

|

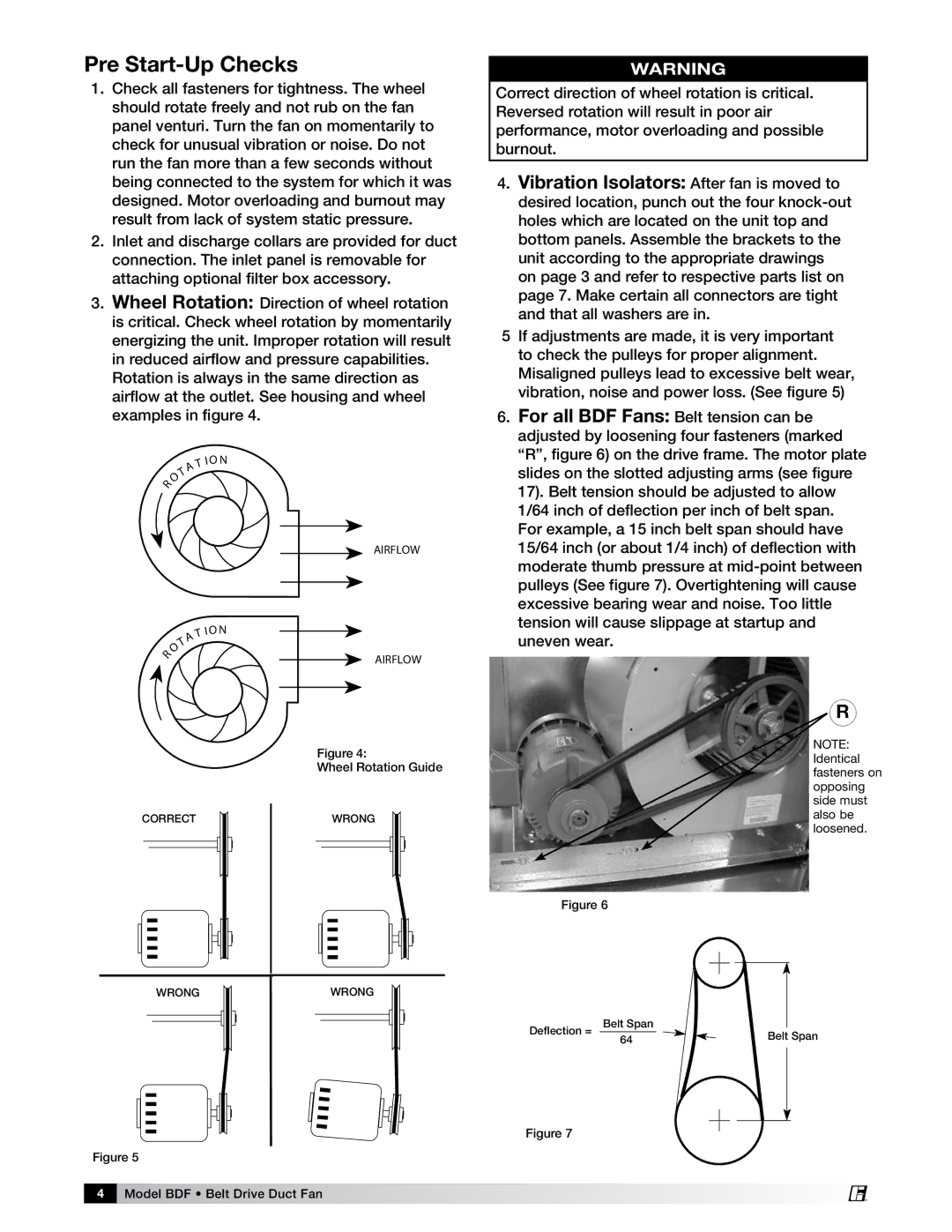

Excessive noise | Belts too tight or too loose | Adjust tension, see figure 7. |

or vibration | Wheel improperly aligned and | Center wheel on inlet. |

| ||

| rubbing | |

|

| |

|

|

|

| Loose drive or motor pulleys | Align and tighten. See |

|

|

|

| Foreign objects in wheel or housing | Remove objects, check for damage or unbalance. |

|

|

|

| System resistance too high | Check system: Proper operation of backdraft or control dampers, |

| obstruction in ductwork, clean dirty filters. | |

|

| |

|

|

|

Reduced airflow | Unit running backwards | Correct as shown in figure 4. |

|

| |

| Excessive dirt buildup on wheels | Clean wheel. |

|

|

|

| Improper wheel alignment | Center wheel on inlets. See |

|

|

|

6

Model BDF • Belt Drive Duct Fan

®