Instructions for UniShield® Shielded Cable

12.0Prepare Cable

12.1Check to be sure cable size fits within kit size range as shown in Table 1 (page 2).

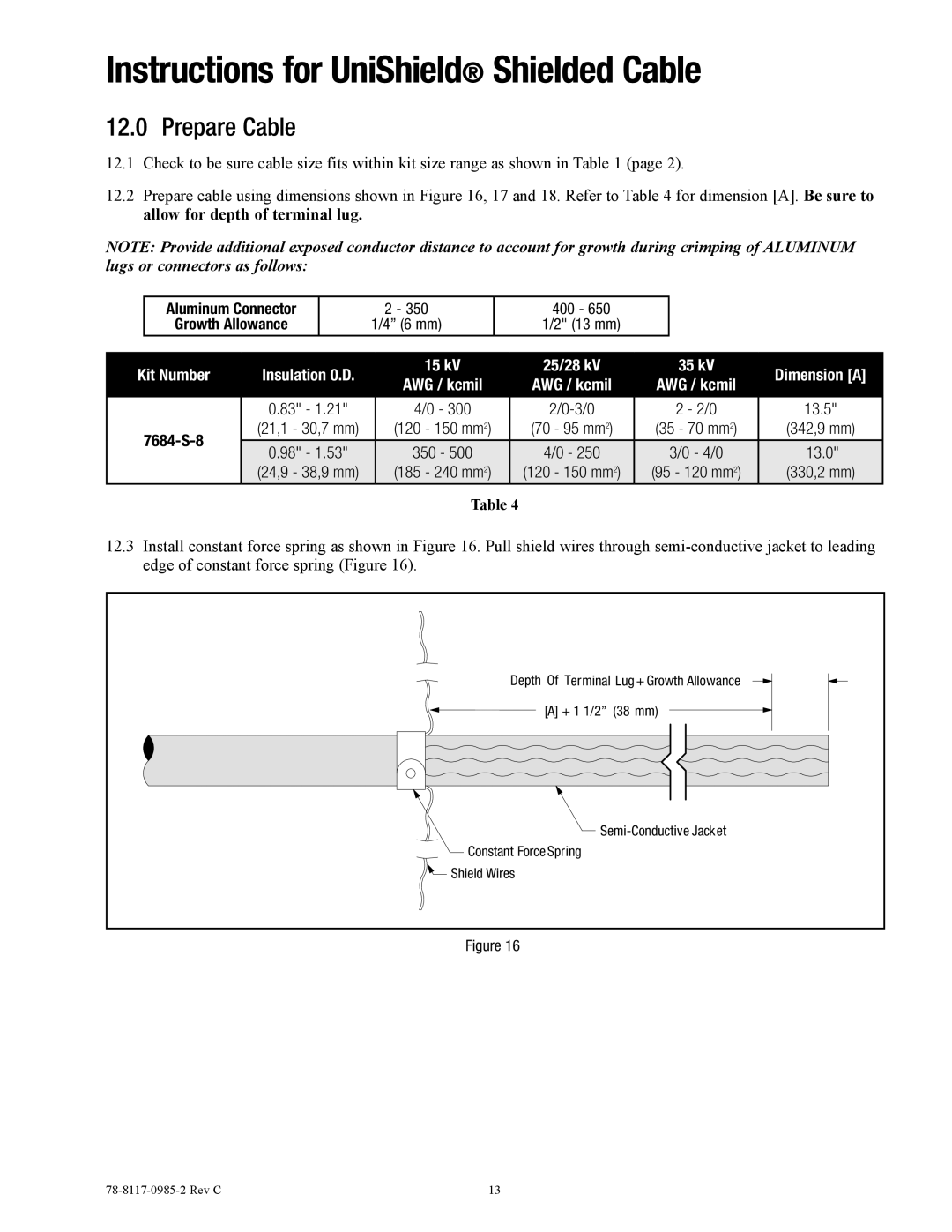

12.2Prepare cable using dimensions shown in Figure 16, 17 and 18. Refer to Table 4 for dimension [A]. Be sure to

allow for depth of terminal lug.

NOTE: Provide additional exposed conductor distance to account for growth during crimping of ALUMINUM lugs or connectors as follows:

| Aluminum Connector |

| 2 - 350 | 400 - 650 |

|

|

| |||

| Growth Allowance |

| 1/4” (6 mm) |

| 1/2" (13 mm) |

|

|

| ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Kit Number | Insulation 0.D. |

| 15 kV |

| 25/28 kV |

| 35 kV | Dimension [A] | ||

| AWG / kcmil |

| AWG / kcmil | AWG / kcmil | ||||||

|

|

|

|

|

|

| ||||

|

| 0.83" - 1.21" |

| 4/0 - 300 |

| 2 - 2/0 | 13.5" | |||

| (21,1 - 30,7 mm) |

| (120 - 150 mm2) |

| (70 - 95 mm2) | (35 - 70 mm2) | (342,9 mm) | |||

|

|

|

|

|

|

|

|

|

| |

| 0.98" - 1.53" |

| 350 - 500 |

| 4/0 - 250 | 3/0 - 4/0 | 13.0" | |||

|

|

|

| |||||||

|

| (24,9 - 38,9 mm) |

| (185 - 240 mm2) |

| (120 - 150 mm2) | (95 - 120 mm2) | (330,2 mm) | ||

|

|

|

|

|

|

|

|

|

|

|

Table 4

12.3Install constant force spring as shown in Figure 16. Pull shield wires through

Depth Of Terminal Lug + Growth Allowance |

[A] + 1 1/2” (38 mm) |

Constant Force Spring |

Shield Wires |

Figure 16

13 |