A.Remove two screws that secure side plate on control box and remove plate.

B.Cut flexible power cord on inside of control box, as close to inside wall as possible.

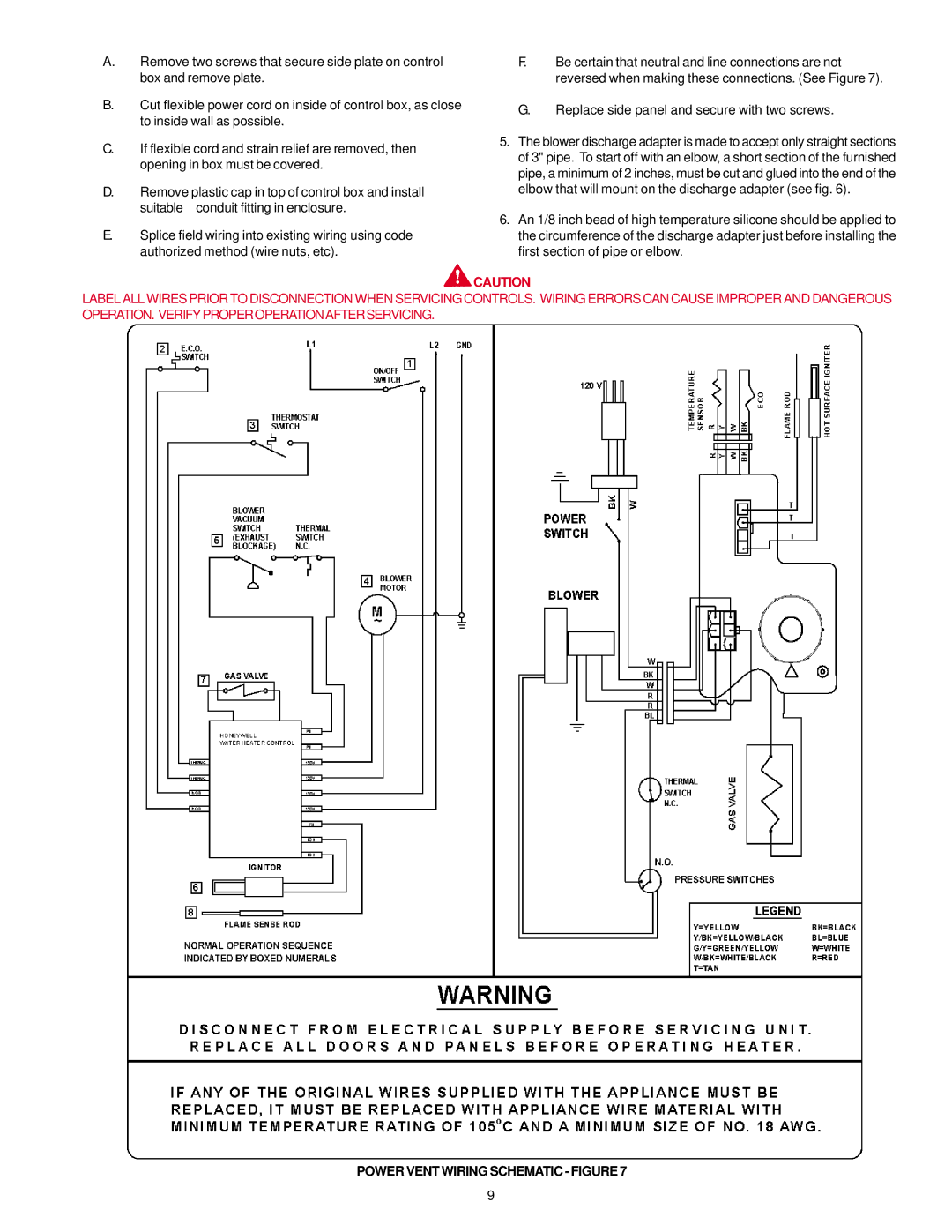

F.Be certain that neutral and line connections are not reversed when making these connections. (See Figure 7).

G.Replace side panel and secure with two screws.

C.If flexible cord and strain relief are removed, then opening in box must be covered.

D.Remove plastic cap in top of control box and install

suitable conduit fitting in enclosure.

E.Splice field wiring into existing wiring using code authorized method (wire nuts, etc).

5.The blower discharge adapter is made to accept only straight sections of 3" pipe. To start off with an elbow, a short section of the furnished pipe, a minimum of 2 inches, must be cut and glued into the end of the elbow that will mount on the discharge adapter (see fig. 6).

6.An 1/8 inch bead of high temperature silicone should be applied to the circumference of the discharge adapter just before installing the first section of pipe or elbow.

![]() CAUTION

CAUTION

LABEL ALL WIRES PRIOR TO DISCONNECTION WHEN SERVICING CONTROLS. WIRING ERRORS CAN CAUSE IMPROPER AND DANGEROUS OPERATION. VERIFYPROPEROPERATIONAFTERSERVICING.

POWER VENT WIRING SCHEMATIC - FIGURE 7

9