WARNING

WARNING

DO NOT USE THIS APPLIANCE IF ANY PART HAS BEEN UNDER WATER. IMMEDIATELY CALL A QUALIFIED SERVICE TECHNICIAN TO INSPECT THE APPLIANCE AND TO REPLACE ANY PART OF THE CONTROL SYSTEM AND ANY GAS CONTROL WHICH HAS BEEN UNDER WATER.

CLEARANCES

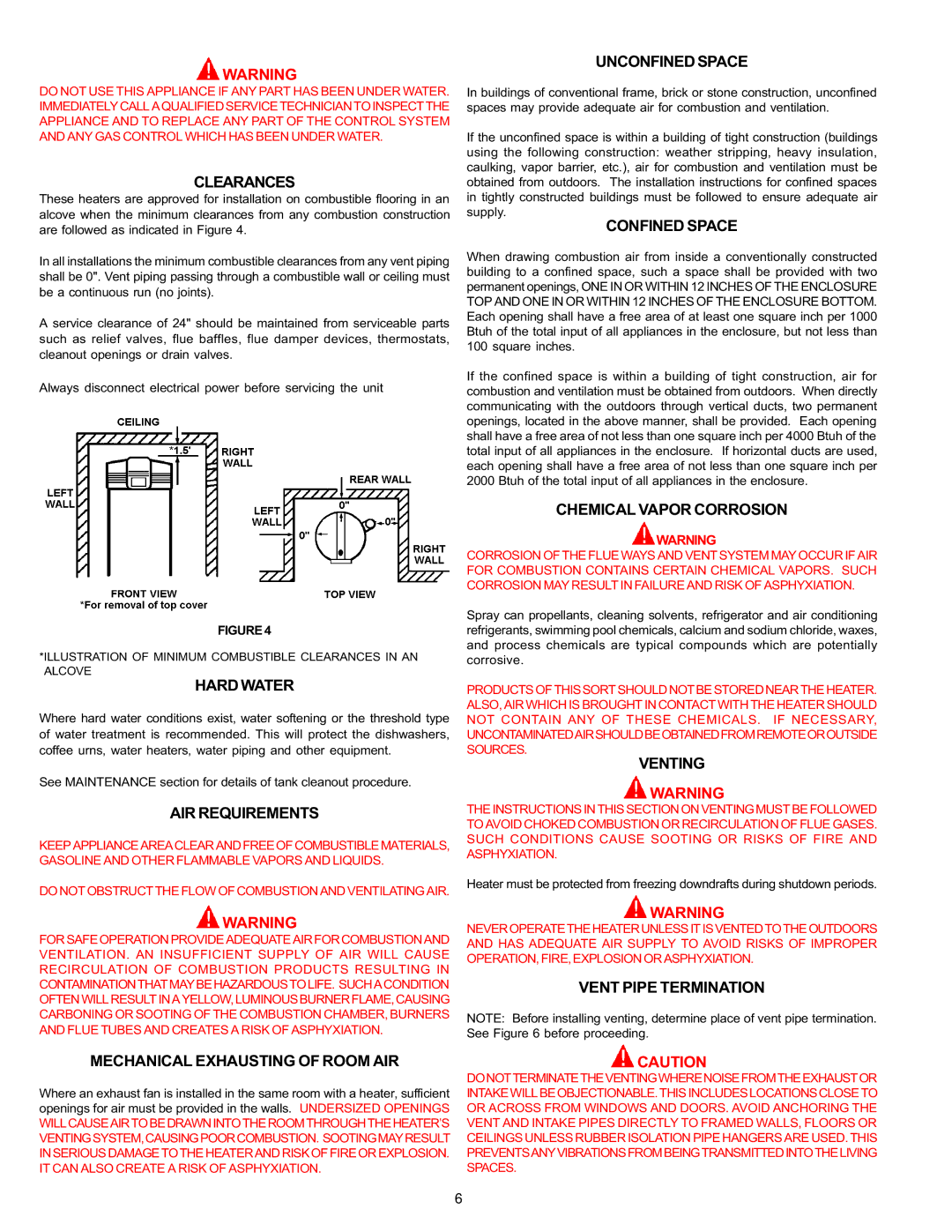

These heaters are approved for installation on combustible flooring in an alcove when the minimum clearances from any combustion construction are followed as indicated in Figure 4.

In all installations the minimum combustible clearances from any vent piping shall be 0". Vent piping passing through a combustible wall or ceiling must be a continuous run (no joints).

A service clearance of 24" should be maintained from serviceable parts such as relief valves, flue baffles, flue damper devices, thermostats, cleanout openings or drain valves.

Always disconnect electrical power before servicing the unit

FIGURE 4

*ILLUSTRATION OF MINIMUM COMBUSTIBLE CLEARANCES IN AN ALCOVE

HARD WATER

Where hard water conditions exist, water softening or the threshold type of water treatment is recommended. This will protect the dishwashers, coffee urns, water heaters, water piping and other equipment.

See MAINTENANCE section for details of tank cleanout procedure.

AIR REQUIREMENTS

KEEPAPPLIANCEAREACLEARANDFREEOFCOMBUSTIBLEMATERIALS, GASOLINE AND OTHER FLAMMABLE VAPORS AND LIQUIDS.

DO NOT OBSTRUCT THE FLOW OF COMBUSTION AND VENTILATING AIR.

WARNING

WARNING

FOR SAFE OPERATION PROVIDE ADEQUATE AIR FOR COMBUSTION AND VENTILATION. AN INSUFFICIENT SUPPLY OF AIR WILL CAUSE RECIRCULATION OF COMBUSTION PRODUCTS RESULTING IN CONTAMINATIONTHATMAYBEHAZARDOUSTOLIFE. SUCHACONDITION OFTEN WILL RESULT IN A YELLOW, LUMINOUS BURNER FLAME, CAUSING CARBONING OR SOOTING OF THE COMBUSTION CHAMBER, BURNERS AND FLUE TUBES AND CREATES A RISK OF ASPHYXIATION.

MECHANICAL EXHAUSTING OF ROOM AIR

Where an exhaust fan is installed in the same room with a heater, sufficient openings for air must be provided in the walls. UNDERSIZED OPENINGS WILLCAUSEAIRTOBEDRAWNINTOTHEROOMTHROUGHTHEHEATER’S VENTINGSYSTEM,CAUSINGPOORCOMBUSTION. SOOTINGMAYRESULT IN SERIOUS DAMAGE TO THE HEATER AND RISK OF FIRE OR EXPLOSION. IT CAN ALSO CREATE A RISK OF ASPHYXIATION.

UNCONFINED SPACE

In buildings of conventional frame, brick or stone construction, unconfined spaces may provide adequate air for combustion and ventilation.

If the unconfined space is within a building of tight construction (buildings using the following construction: weather stripping, heavy insulation, caulking, vapor barrier, etc.), air for combustion and ventilation must be obtained from outdoors. The installation instructions for confined spaces in tightly constructed buildings must be followed to ensure adequate air supply.

CONFINED SPACE

When drawing combustion air from inside a conventionally constructed building to a confined space, such a space shall be provided with two permanent openings, ONE IN OR WITHIN 12 INCHES OF THE ENCLOSURE TOP AND ONE IN OR WITHIN 12 INCHES OF THE ENCLOSURE BOTTOM. Each opening shall have a free area of at least one square inch per 1000 Btuh of the total input of all appliances in the enclosure, but not less than 100 square inches.

If the confined space is within a building of tight construction, air for combustion and ventilation must be obtained from outdoors. When directly communicating with the outdoors through vertical ducts, two permanent openings, located in the above manner, shall be provided. Each opening shall have a free area of not less than one square inch per 4000 Btuh of the total input of all appliances in the enclosure. If horizontal ducts are used, each opening shall have a free area of not less than one square inch per 2000 Btuh of the total input of all appliances in the enclosure.

CHEMICAL VAPOR CORROSION

WARNING

WARNING

CORROSION OF THE FLUE WAYS AND VENT SYSTEM MAY OCCUR IF AIR FOR COMBUSTION CONTAINS CERTAIN CHEMICAL VAPORS. SUCH CORROSION MAY RESULT IN FAILURE AND RISK OF ASPHYXIATION.

Spray can propellants, cleaning solvents, refrigerator and air conditioning refrigerants, swimming pool chemicals, calcium and sodium chloride, waxes, and process chemicals are typical compounds which are potentially corrosive.

PRODUCTS OF THIS SORT SHOULD NOT BE STORED NEAR THE HEATER. ALSO, AIR WHICH IS BROUGHT IN CONTACT WITH THE HEATER SHOULD NOT CONTAIN ANY OF THESE CHEMICALS. IF NECESSARY, UNCONTAMINATEDAIRSHOULDBEOBTAINEDFROMREMOTEOROUTSIDE SOURCES.

VENTING

WARNING

WARNING

THE INSTRUCTIONS IN THIS SECTION ON VENTING MUST BE FOLLOWED TO AVOID CHOKED COMBUSTION OR RECIRCULATION OF FLUE GASES. SUCH CONDITIONS CAUSE SOOTING OR RISKS OF FIRE AND ASPHYXIATION.

Heater must be protected from freezing downdrafts during shutdown periods.

WARNING

WARNING

NEVEROPERATETHEHEATERUNLESSITISVENTEDTOTHEOUTDOORS AND HAS ADEQUATE AIR SUPPLY TO AVOID RISKS OF IMPROPER OPERATION, FIRE, EXPLOSION OR ASPHYXIATION.

VENT PIPE TERMINATION

NOTE: Before installing venting, determine place of vent pipe termination. See Figure 6 before proceeding.

CAUTION

CAUTION

DONOTTERMINATETHEVENTINGWHERENOISEFROMTHEEXHAUSTOR INTAKE WILL BE OBJECTIONABLE. THIS INCLUDES LOCATIONS CLOSE TO OR ACROSS FROM WINDOWS AND DOORS. AVOID ANCHORING THE VENT AND INTAKE PIPES DIRECTLY TO FRAMED WALLS, FLOORS OR CEILINGS UNLESS RUBBER ISOLATION PIPE HANGERS ARE USED. THIS PREVENTSANYVIBRATIONSFROMBEINGTRANSMITTEDINTOTHELIVING SPACES.