|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Mounting Information |

|

|

|

|

|

|

|

|

|

|

| SENC 150 |

|

|

| |||||||||

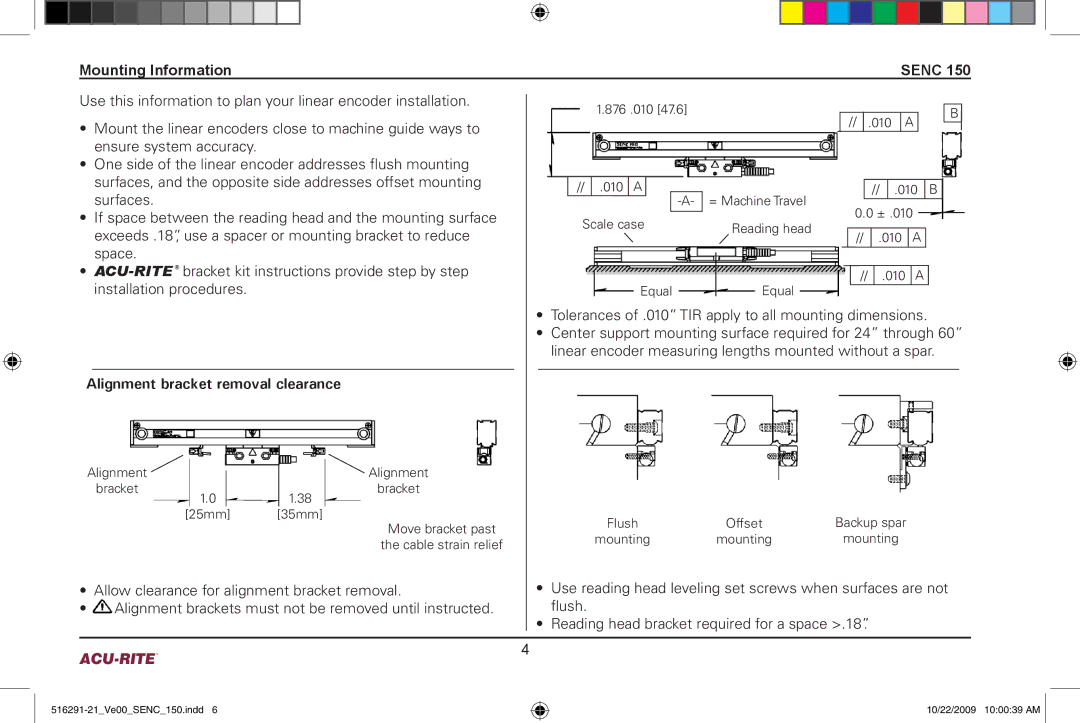

Use this information to plan your linear encoder installation.

• | Mount the linear encoders close to machine guide ways to |

| ensure system accuracy. |

• | One side of the linear encoder addresses flush mounting |

1.876 .010 [47.6] |

|

|

|

|

|

|

|

|

| B | |

// | .010 | A |

| ||

|

|

|

surfaces, and the opposite side addresses offset mounting |

surfaces. |

• If space between the reading head and the mounting surface |

exceeds .18”, use a spacer or mounting bracket to reduce |

space. |

• |

installation procedures. |

//.010 A

|

| = Machine Travel | |

| |||

|

|

| |

Scale case | Reading head | ||

|

|

| |

Equal | Equal | ||

//.010 B

0.0± .010

//.010 A

//.010 A

Alignment bracket removal clearance

Alignment |

|

| Alignment |

bracket | 1.0 | 1.38 | bracket |

|

| ||

| [25mm] | [35mm] |

|

Move bracket past

the cable strain relief

•Allow clearance for alignment bracket removal.

•![]() Alignment brackets must not be removed until instructed.

Alignment brackets must not be removed until instructed.

•Tolerances of .010” TIR apply to all mounting dimensions.

•Center support mounting surface required for 24” through 60” linear encoder measuring lengths mounted without a spar.

Flush | Offset | Backup spar |

mounting | mounting | mounting |

•Use reading head leveling set screws when surfaces are not flush.

•Reading head bracket required for a space >.18”.

| 4 |

10/22/2009 10:00:39 AM ![]()