OPERATION

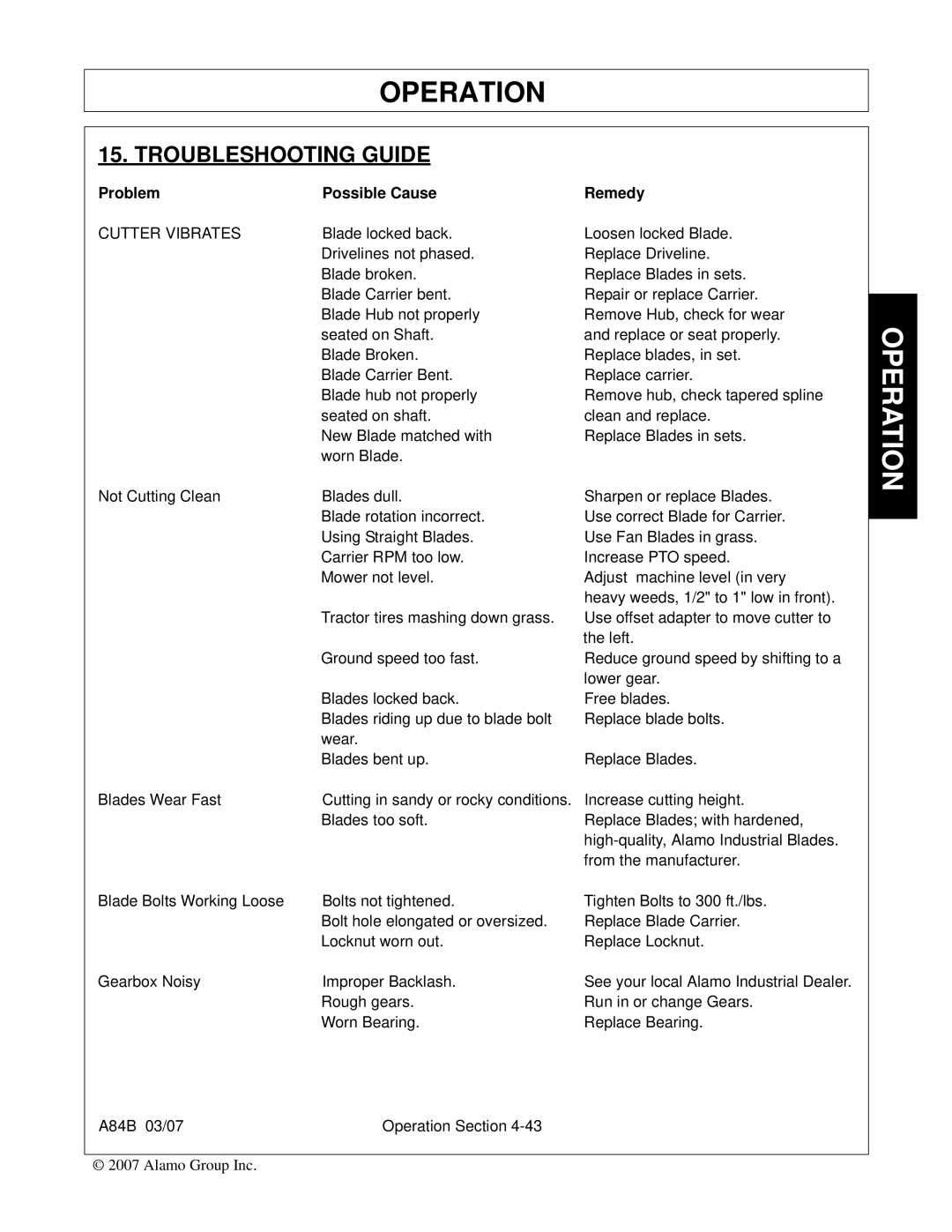

15. TROUBLESHOOTING GUIDE

Problem | Possible Cause | Remedy |

CUTTER VIBRATES | Blade locked back. | Loosen locked Blade. |

| Drivelines not phased. | Replace Driveline. |

| Blade broken. | Replace Blades in sets. |

| Blade Carrier bent. | Repair or replace Carrier. |

| Blade Hub not properly | Remove Hub, check for wear |

| seated on Shaft. | and replace or seat properly. |

| Blade Broken. | Replace blades, in set. |

| Blade Carrier Bent. | Replace carrier. |

| Blade hub not properly | Remove hub, check tapered spline |

| seated on shaft. | clean and replace. |

| New Blade matched with | Replace Blades in sets. |

| worn Blade. |

|

Not Cutting Clean | Blades dull. | Sharpen or replace Blades. |

| Blade rotation incorrect. | Use correct Blade for Carrier. |

| Using Straight Blades. | Use Fan Blades in grass. |

| Carrier RPM too low. | Increase PTO speed. |

| Mower not level. | Adjust machine level (in very |

|

| heavy weeds, 1/2" to 1" low in front). |

| Tractor tires mashing down grass. | Use offset adapter to move cutter to |

|

| the left. |

| Ground speed too fast. | Reduce ground speed by shifting to a |

|

| lower gear. |

| Blades locked back. | Free blades. |

| Blades riding up due to blade bolt | Replace blade bolts. |

| wear. |

|

| Blades bent up. | Replace Blades. |

Blades Wear Fast | Cutting in sandy or rocky conditions. | Increase cutting height. |

| Blades too soft. | Replace Blades; with hardened, |

|

| |

|

| from the manufacturer. |

Blade Bolts Working Loose | Bolts not tightened. | Tighten Bolts to 300 ft./lbs. |

| Bolt hole elongated or oversized. | Replace Blade Carrier. |

| Locknut worn out. | Replace Locknut. |

Gearbox Noisy | Improper Backlash. | See your local Alamo Industrial Dealer. |

| Rough gears. | Run in or change Gears. |

| Worn Bearing. | Replace Bearing. |

A84B 03/07 | Operation Section |

© 2007 Alamo Group Inc.