OPERATION

OPERATION

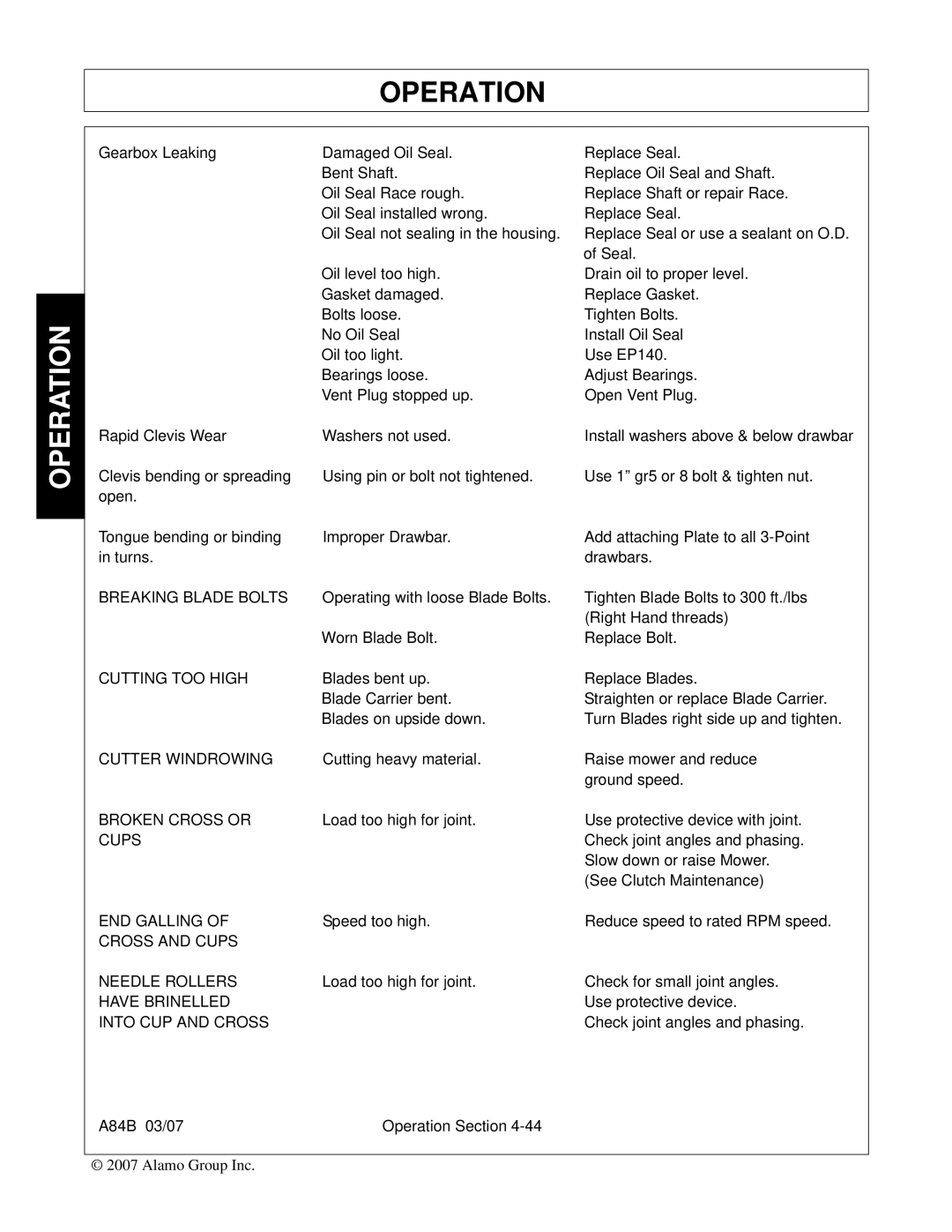

Gearbox Leaking | Damaged Oil Seal. | Replace Seal. |

| Bent Shaft. | Replace Oil Seal and Shaft. |

| Oil Seal Race rough. | Replace Shaft or repair Race. |

| Oil Seal installed wrong. | Replace Seal. |

| Oil Seal not sealing in the housing. | Replace Seal or use a sealant on O.D. |

|

| of Seal. |

| Oil level too high. | Drain oil to proper level. |

| Gasket damaged. | Replace Gasket. |

| Bolts loose. | Tighten Bolts. |

| No Oil Seal | Install Oil Seal |

| Oil too light. | Use EP140. |

| Bearings loose. | Adjust Bearings. |

| Vent Plug stopped up. | Open Vent Plug. |

Rapid Clevis Wear | Washers not used. | Install washers above & below drawbar |

Clevis bending or spreading | Using pin or bolt not tightened. | Use 1” gr5 or 8 bolt & tighten nut. |

open. |

|

|

Tongue bending or binding | Improper Drawbar. | Add attaching Plate to all |

in turns. |

| drawbars. |

BREAKING BLADE BOLTS | Operating with loose Blade Bolts. | Tighten Blade Bolts to 300 ft./lbs |

|

| (Right Hand threads) |

| Worn Blade Bolt. | Replace Bolt. |

CUTTING TOO HIGH | Blades bent up. | Replace Blades. |

| Blade Carrier bent. | Straighten or replace Blade Carrier. |

| Blades on upside down. | Turn Blades right side up and tighten. |

CUTTER WINDROWING | Cutting heavy material. | Raise mower and reduce |

|

| ground speed. |

BROKEN CROSS OR | Load too high for joint. | Use protective device with joint. |

CUPS |

| Check joint angles and phasing. |

|

| Slow down or raise Mower. |

|

| (See Clutch Maintenance) |

END GALLING OF | Speed too high. | Reduce speed to rated RPM speed. |

CROSS AND CUPS |

|

|

NEEDLE ROLLERS | Load too high for joint. | Check for small joint angles. |

HAVE BRINELLED |

| Use protective device. |

INTO CUP AND CROSS |

| Check joint angles and phasing. |

A84B 03/07 | Operation Section |

© 2007 Alamo Group Inc.