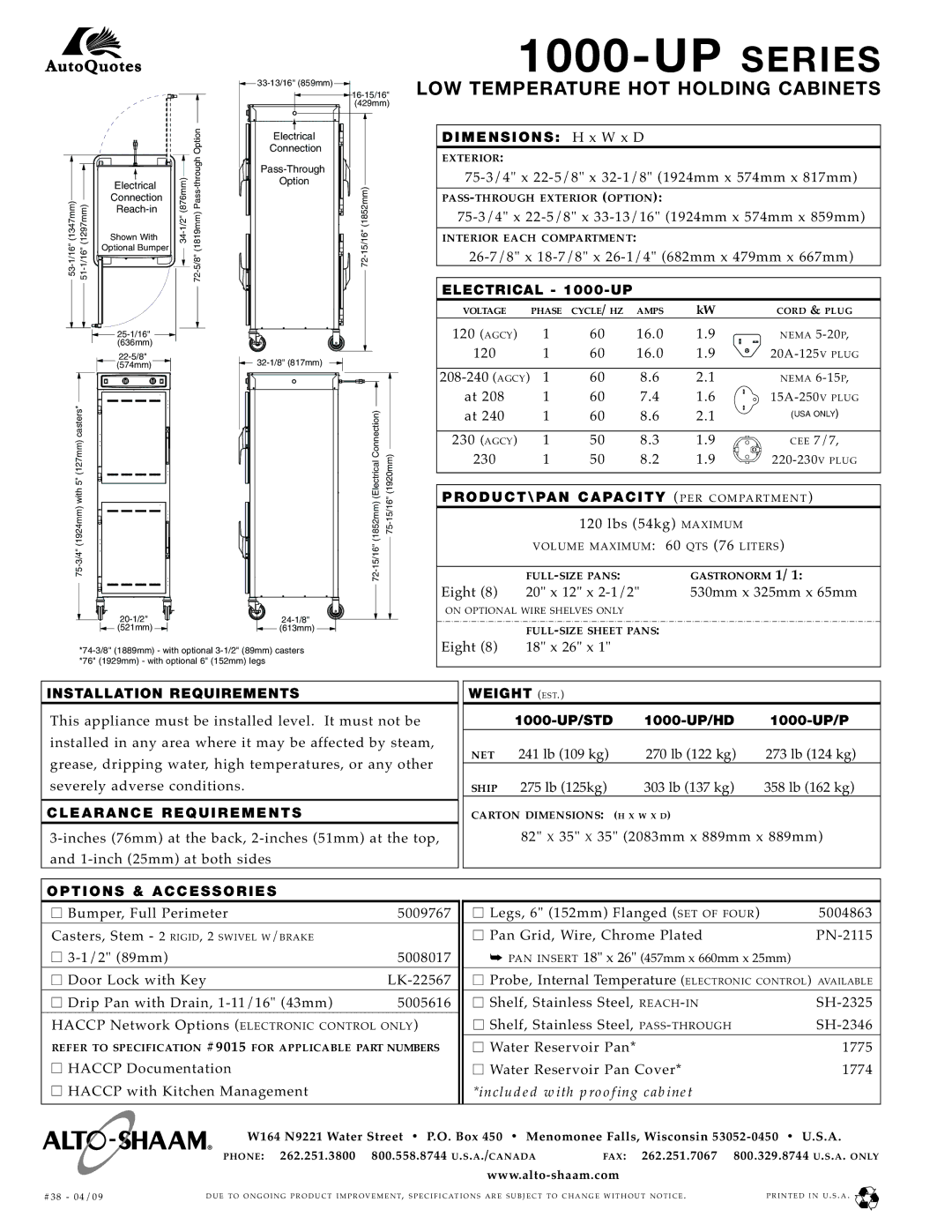

1000-UP/ STD, 1000-UP/ P*, 1000-UP/ HD specifications

Alto-Shaam has built a reputation for delivering high-quality food service equipment, and their line of cook-and-hold ovens exemplifies this commitment. Among their flagship products are the Alto-Shaam 1000-UP/HD, 1000-UP/P*, and 1000-UP/STD models. Each of these units is designed to meet the diverse needs of kitchens while enhancing cooking efficiency and food quality.One of the standout features of the 1000-UP series is its patented Halo Heat® technology. This unique method of cooking uses gentle, circulating heat to ensure food is cooked evenly without compromising moisture and texture. The result is perfectly cooked meats and vegetables that are held at optimal serving temperatures without drying out. This technology minimizes shrinkage and maximizes yield, an essential consideration for any commercial kitchen.

Another key characteristic of these models is their impressive capacity. The 1000-UP series can hold up to 10 full-size food pans, catering to high-volume operations efficiently. Their spacious design allows chefs to prepare and hold larger quantities of food with ease, whether for banquets, buffets, or busy dining services.

Moreover, these ovens feature a digital control system, allowing operators to precisely set cooking and holding temperatures. The intuitive display makes it easy to navigate and adjust settings, improving workflow during busy kitchen hours. With a temperature range that extends from a low hold of 140°F to a high cook of 325°F, chefs can customize their cooking methods to meet various menu requirements.

The 1000-UP models are also designed with energy efficiency in mind. The use of Halo Heat® not only provides superior cooking performance but also reduces energy costs. These ovens are constructed with high-quality materials that ensure durability and long-lasting performance, an essential factor in a fast-paced kitchen environment.

Safety and ease of use are also elevated in these models. The ovens feature a cool-to-touch exterior, allowing for safe operation in high-traffic areas. Additionally, the smooth interior surfaces facilitate easy cleaning, ensuring compliance with health and safety standards.

Overall, the Alto-Shaam 1000-UP/HD, 1000-UP/P*, and 1000-UP/STD models set a high standard in the culinary industry, combining innovative technology with practicality. They provide culinary professionals with the tools necessary to elevate their cooking while ensuring quality, efficiency, and safety in their operation. This makes them indispensable in contemporary food service establishments looking to maximize performance and maintain high food quality.