1000-SK/II, 1000-SK-I, 1767-SK, 767-SK specifications

Alto-Shaam has established itself as a leader in the foodservice equipment industry, particularly known for its innovative cooking and holding technologies. Among its premier offerings are the Alto-Shaam 767-SK, 1767-SK, 1000-SK-I, and 1000-SK/II models, each designed to meet the diverse needs of commercial kitchens while promoting efficiency, quality, and simplicity.The Alto-Shaam 767-SK stands out with its ability to provide consistent heated holding for various foods. Featuring Signature Cook & Hold technology, this unit can hold food at precise temperatures, which helps to enhance flavors and maintain quality. With a temperature range of 140°F to 200°F, it is ideal for items such as roasted meats and baked goods. Its design also allows for easy cleaning and maintenance, ensuring long-term reliability in busy kitchen environments.

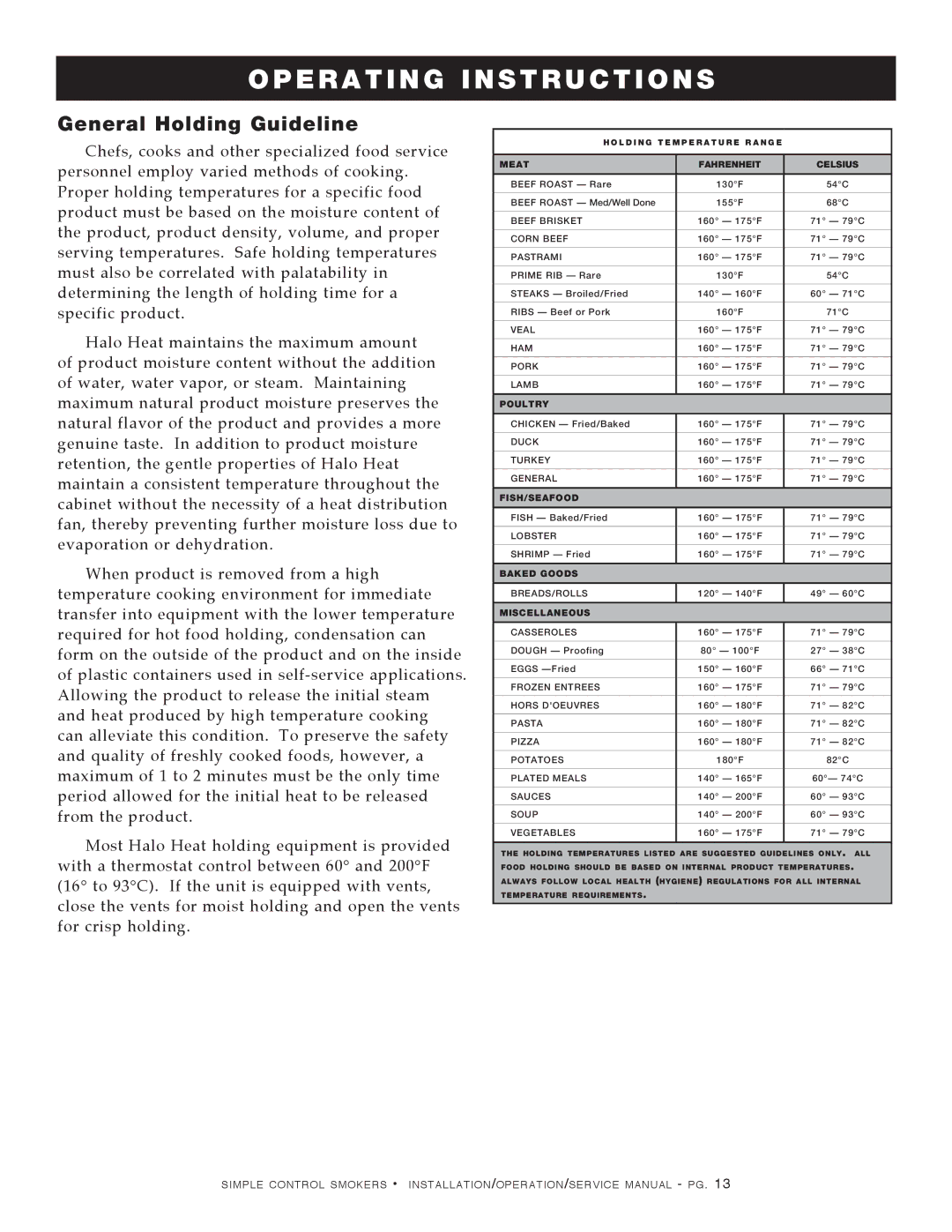

The 1767-SK model is a versatile holding cabinet that places an emphasis on space efficiency without compromising capacity. With a compact footprint, it accommodates a variety of food items while maintaining optimal temperature control. This model employs a patented Halo Heat technology, designed to provide even heat distribution, preventing moisture loss and preserving food texture and taste.

The Alto-Shaam 1000-SK-I and 1000-SK/II further enhance the brand's reputation for quality with advanced features tailored for high-demand settings. Both models integrate Smart Control technology, allowing operators to program and monitor cooking parameters digitally. This capability ensures consistent results and reduces variations in food quality, which is critical for establishments focused on delivering an exceptional dining experience.

A notable common feature across these models is their energy efficiency. Utilizing innovative thermal technology, these units require less power compared to traditional options, making them environmentally friendly and cost-effective for any foodservice operation. Additionally, all models come equipped with durable stainless steel construction, ensuring long-lasting performance even in the most demanding kitchen environments.

In summary, the Alto-Shaam 767-SK, 1767-SK, 1000-SK-I, and 1000-SK/II represent a blend of advanced technology, efficient design, and consistent performance. Whether in a restaurant, catering operation, or institutional kitchen, these units cater to the specific needs of operators and chefs, ensuring that every dish served is of the highest possible quality. By investing in these innovative solutions, establishments can effectively improve their service and maintain customer satisfaction.