3.Piping/Connections

ALL components/materials must conform to National Fuel Gas Code Specifications ANSI

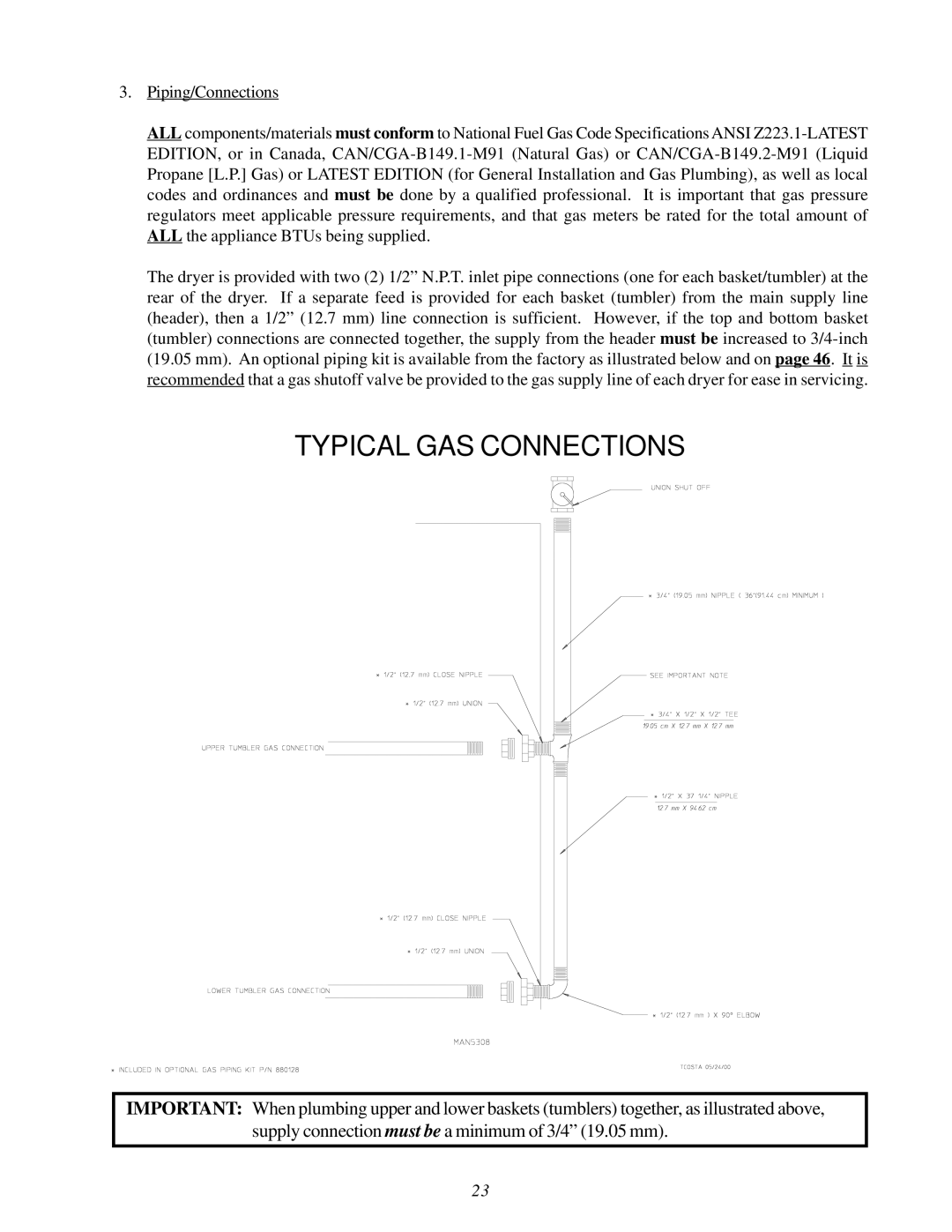

The dryer is provided with two (2) 1/2” N.P.T. inlet pipe connections (one for each basket/tumbler) at the rear of the dryer. If a separate feed is provided for each basket (tumbler) from the main supply line (header), then a 1/2” (12.7 mm) line connection is sufficient. However, if the top and bottom basket (tumbler) connections are connected together, the supply from the header must be increased to

TYPICAL GAS CONNECTIONS

IMPORTANT: When plumbing upper and lower baskets (tumblers) together, as illustrated above, supply connection must be a minimum of 3/4” (19.05 mm).

23