REDUCING OUTPUT CURRENT

Reducing the output current in the MDM60001 can be accomplished by connecting an external resistor (1/8 watt or higher) between pins 1 and 2 of connector P2 and ocurrs automatically 1 second after the last positive going edge of the step clock input. See Figure 1 for TYPICAL

The amount of current per Phase in the reduction mode is related to the value of the current adjustment resistor and the current reduction resistor. When the current reduction circuit is activated, the current reduction resistor is paralleled with the current adjustment resistor. This lowers the total resistance value, and thus lowers the per Phase output current. The relationship between the output current and the resistor's value is as follows:

RMS Reduction Current (Amps)=(.707)(.002)xR(Adjust)xR(Reduction)

R(Adjust)+R(Reduction)

NOTE: When connecting the current reduction resistor between pins 1 and 2 of connector P2 , the length of the leads should be as short as possible to help minimize noise coupled into the driver.

MOTOR SELECTION

The MDM60001 is a Bipolar driver working equally well with both Bipolar and Unipolar Motor Configurations,( i.e. 8 and 4 lead motors and 6 lead center tapped motors).

Motors with low current ratings and high inductance will perform better at low speeds, providing higher

Since the MDM60001 is a constant current source, it is not necessary to use a motor that is rated at the same voltage as the supply voltage. What is important is that the MDM60001 is set to the appropriate current level based on the motor being used.

Higher voltages will cause the current to flow faster through the motor coils. This in turn means higher step rates can be achieved. Care should be taken not to exceed the maximum voltage of the driver.

STEP MOTOR CONFIGURATIONS

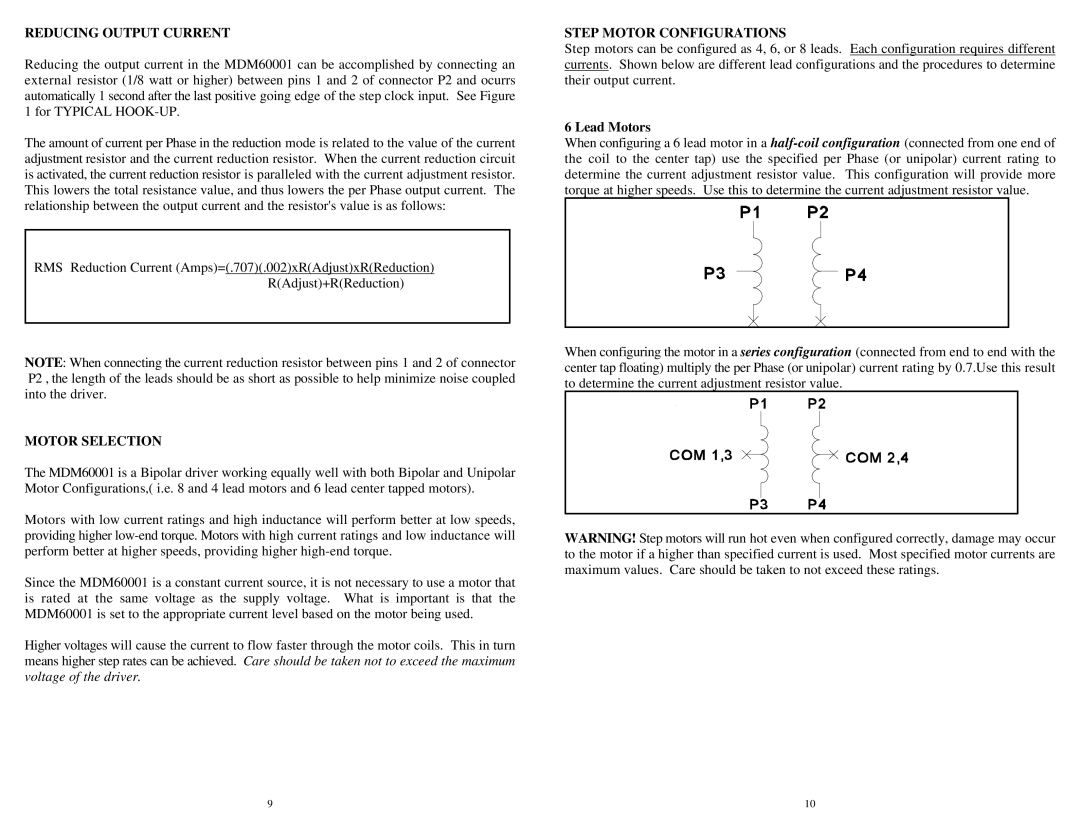

Step motors can be configured as 4, 6, or 8 leads. Each configuration requires different currents. Shown below are different lead configurations and the procedures to determine their output current.

6 Lead Motors

When configuring a 6 lead motor in a

When configuring the motor in a series configuration (connected from end to end with the center tap floating) multiply the per Phase (or unipolar) current rating by 0.7.Use this result to determine the current adjustment resistor value.

WARNING! Step motors will run hot even when configured correctly, damage may occur to the motor if a higher than specified current is used. Most specified motor currents are maximum values. Care should be taken to not exceed these ratings.

9 | 10 |