Installation (Continued)

NOTE: Use an adhesive primer to ensure adhesive joints are secure. Suregard P-3000 has a purple tracer to qualify in areas where codes specify a primer must be used.

Consider climatic conditions when applying adhesives. Atmospheric condi- tions with high humidity will make the adhesive action of certain glues less effective. Follow the manufacturer’s instructions.

THREADED CONNECTIONS

Use only Teflon® tape or equivalent on threaded plumbing connections. Other pipe compounds may damage threads. Do not use silicone or petroleum based compounds. Do not overtighten. Hand tightening plus 1/2 turn is sufficient.

PUMP PLUMBING

Suction pipe should be as large or larger than discharge pipe. Avoid using a suc- tion pipe smaller than pump connection.

1.Keep the piping as straight and short as possible, and of suitable size.

2.Do not connect an elbow directly into the pump inlet. A length of straight pipe will allow proper entry of the water to the pump.

3.Slope horizontal runs upward to the pump to prevent trapping air.

4.Use independent piping supports to alleviate strain on the pump.

5.Keep as much of the suction line as possible below the water level to reduce priming time.

6.Install valves and unions in the pump suction and return lines to facilitate servicing. Valves will throt- tle the pump discharge. Valves are also essential for pump mainte- nance if the system is installed below deck level.

7.Use a check valve in the suction pipe for inground pumps at or below the water level if the suction lift is more than 5 feet or the dry suction is more than 10 feet long. Keep the valve in the suction line fully open during operation.

WIRING

! WARNING All

wiring must be performed by a qualified electrician. The pump must be installed

in compliance with all local codes and the National Electrical Code.

When motor installation is within 5 ft. (1.5 m) of the pool’s interior walls, a solid copper bonding conductor (mini- mum size No. 8 AWG/8.4 mm2) should be connected from the accessible wire connector on the motor.

•to all metal parts of the swimming pool

•to all electrical equipment

•to metal conduit

•to metal piping within 5 ft. (1.5 m) of the pool’s interior walls

IMPORTANT: Use copper conductors only.

Refer to information on motor name- plate for electrical service data. Install motors with a fused disconnect switch or dedicated circuit breaker. Be sure wire size is sufficient for pump HP and distance from power source. Install a ground fault circuit interrupter for maximum safety.

Disconnect, tag,

! DANGER and lock out power source before attempting to install, ser- vice, relocate, or perform any mainte- nance.

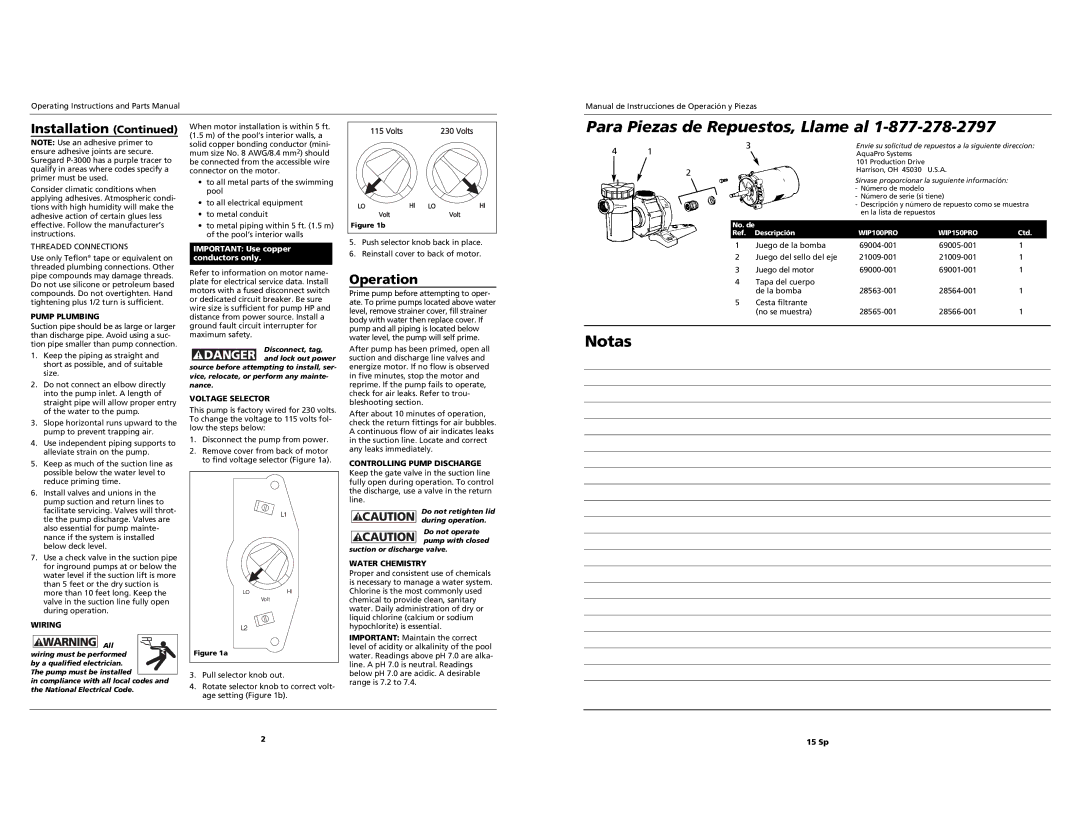

VOLTAGE SELECTOR

This pump is factory wired for 230 volts. To change the voltage to 115 volts fol- low the steps below:

1.Disconnect the pump from power.

2.Remove cover from back of motor to find voltage selector (Figure 1a).

L1

LOHI

Volt

L2

Figure 1a

3.Pull selector knob out.

4.Rotate selector knob to correct volt- age setting (Figure 1b).

Figure 1b

5.Push selector knob back in place.

6.Reinstall cover to back of motor.

Operation

Prime pump before attempting to oper- ate. To prime pumps located above water level, remove strainer cover, fill strainer body with water then replace cover. If pump and all piping is located below water level, the pump will self prime.

After pump has been primed, open all suction and discharge line valves and energize motor. If no flow is observed in five minutes, stop the motor and reprime. If the pump fails to operate, check for air leaks. Refer to trou- bleshooting section.

After about 10 minutes of operation, check the return fittings for air bubbles. A continuous flow of air indicates leaks in the suction line. Locate and correct any leaks immediately.

CONTROLLING PUMP DISCHARGE

Keep the gate valve in the suction line fully open during operation. To control the discharge, use a valve in the return line.

Do not retighten lid

! CAUTION during operation.

Do not operate

! CAUTION pump with closed suction or discharge valve.

WATER CHEMISTRY

Proper and consistent use of chemicals is necessary to manage a water system. Chlorine is the most commonly used chemical to provide clean, sanitary water. Daily administration of dry or liquid chlorine (calcium or sodium hypochlorite) is essential.

IMPORTANT: Maintain the correct level of acidity or alkalinity of the pool water. Readings above pH 7.0 are alka- line. A pH 7.0 is neutral. Readings below pH 7.0 are acidic. A desirable range is 7.2 to 7.4.

Para Piezas de Repuestos, Llame al 1-877-278-2797

4 | 3 | | Envíe su solicitud de repuestos a la siguiente direccion: |

1 | | | AquaPro Systems | | |

| | | | 101 Production Drive | | |

| 2 | | | Harrison, OH 45030 | U.S.A. | |

| | | | Sírvase proporcionar la suguiente información: | |

| | | | |

| | | | - Número de modelo | | |

| | | | | |

| | | | - Número de serie (si tiene) | |

| | | | |

| | | | - Descripción y número de repuesto como se muestra |

| | | | en la lista de repuestos | |

| | | | | |

| | No. de | | | |

| | Ref. | Descripción | WIP100PRO | WIP150PRO | Ctd. |

| 1 | Juego de la bomba | 69004-001 | 69005-001 | 1 |

| 2 | Juego del sello del eje | 21009-001 | 21009-001 | 1 |

| 3 | Juego del motor | 69000-001 | 69001-001 | 1 |

| 4 | Tapa del cuerpo | | | |

| | | de la bomba | 28563-001 | 28564-001 | 1 |

| 5 | Cesta filtrante | | | |

| | | (no se muestra) | 28565-001 | 28566-001 | 1 |

Notas