TIPS FOR OPERATION

Use slow gears when operating the tractor on rough ground, slopes, small areas, near buildings or other obstacles.

Use a slow gear and a fast engine speed when operating a snowblower, rotary cultivator, or a mower in heavy grass.

Walk behind, never between the handlebars.

MAINTENANCE

WARNING: AVOID INJURY. Read and understand entire Safety section before proceeding.

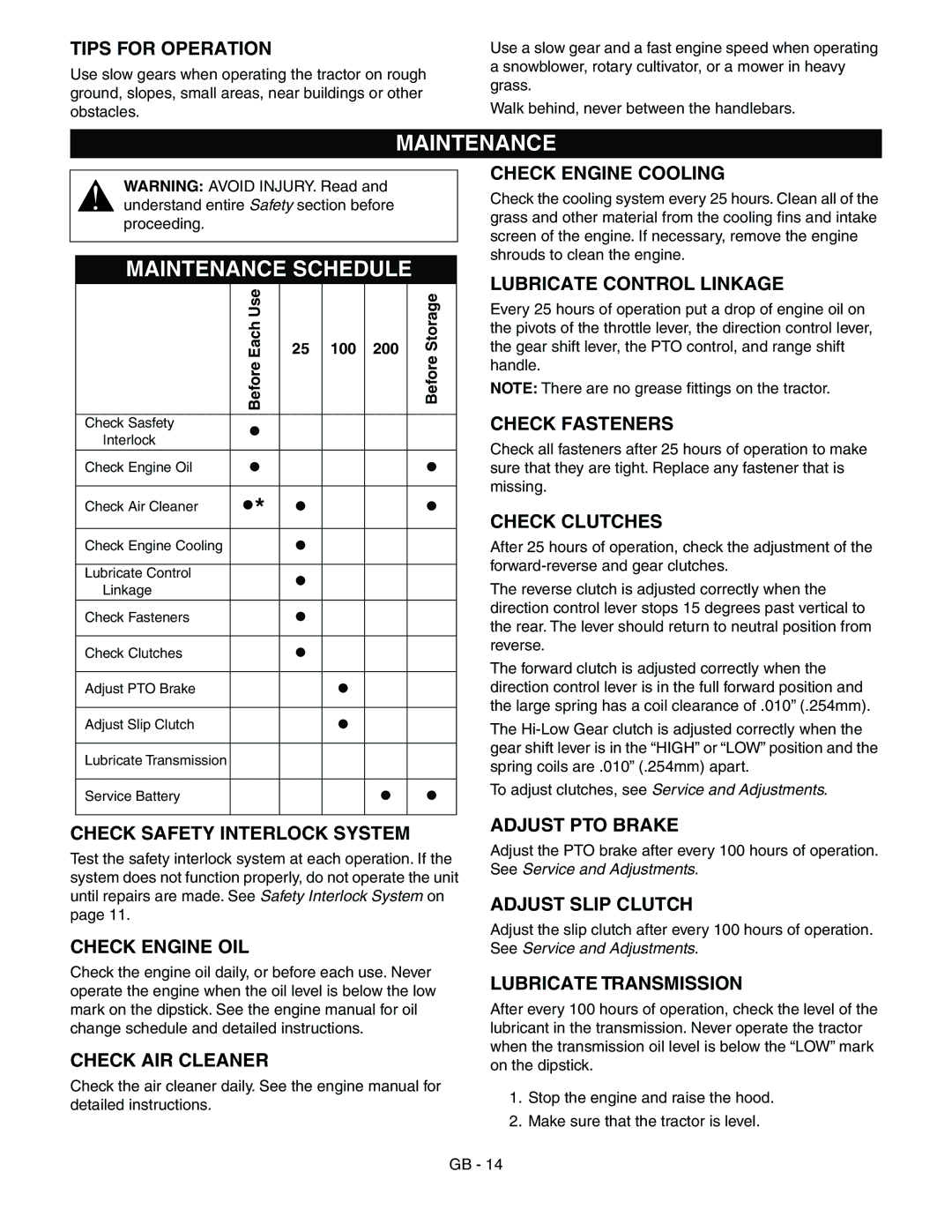

MAINTENANCE SCHEDULE

| Before Each Use | 25 | 100 | 200 | Before Storage |

|

|

|

| ||

|

|

|

|

|

|

Check Sasfety | • |

|

|

|

|

Interlock |

|

|

|

| |

Check Engine Oil | • |

|

|

| • |

Check Air Cleaner | •* | • |

|

| • |

|

|

| |||

|

|

|

|

|

|

Check Engine Cooling |

| • |

|

|

|

Lubricate Control |

| • |

|

|

|

Linkage |

|

|

|

| |

|

|

|

|

|

|

Check Fasteners |

| • |

|

|

|

|

|

|

|

|

|

Check Clutches |

| • |

|

|

|

Adjust PTO Brake |

|

| • |

|

|

|

|

|

|

|

|

Adjust Slip Clutch |

|

| • |

|

|

|

|

|

|

|

|

Lubricate Transmission |

|

|

|

|

|

|

|

|

|

|

|

Service Battery |

|

|

| • | • |

|

|

|

|

|

|

CHECK SAFETY INTERLOCK SYSTEM

Test the safety interlock system at each operation. If the system does not function properly, do not operate the unit until repairs are made. See Safety Interlock System on page 11.

CHECK ENGINE OIL

Check the engine oil daily, or before each use. Never operate the engine when the oil level is below the low mark on the dipstick. See the engine manual for oil change schedule and detailed instructions.

CHECK AIR CLEANER

Check the air cleaner daily. See the engine manual for detailed instructions.

CHECK ENGINE COOLING

Check the cooling system every 25 hours. Clean all of the grass and other material from the cooling fins and intake screen of the engine. If necessary, remove the engine shrouds to clean the engine.

LUBRICATE CONTROL LINKAGE

Every 25 hours of operation put a drop of engine oil on the pivots of the throttle lever, the direction control lever, the gear shift lever, the PTO control, and range shift handle.

NOTE: There are no grease fittings on the tractor.

CHECK FASTENERS

Check all fasteners after 25 hours of operation to make sure that they are tight. Replace any fastener that is missing.

CHECK CLUTCHES

After 25 hours of operation, check the adjustment of the

The reverse clutch is adjusted correctly when the direction control lever stops 15 degrees past vertical to the rear. The lever should return to neutral position from reverse.

The forward clutch is adjusted correctly when the direction control lever is in the full forward position and the large spring has a coil clearance of .010” (.254mm).

The

To adjust clutches, see Service and Adjustments.

ADJUST PTO BRAKE

Adjust the PTO brake after every 100 hours of operation. See Service and Adjustments.

ADJUST SLIP CLUTCH

Adjust the slip clutch after every 100 hours of operation. See Service and Adjustments.

LUBRICATE TRANSMISSION

After every 100 hours of operation, check the level of the lubricant in the transmission. Never operate the tractor when the transmission oil level is below the “LOW” mark on the dipstick.

1.Stop the engine and raise the hood.

2.Make sure that the tractor is level.

GB - 14