www.tradeplumbing.co.uk Call Sales On 08708034288 | |||||||||||||||||||||||||||||||||||||||||||

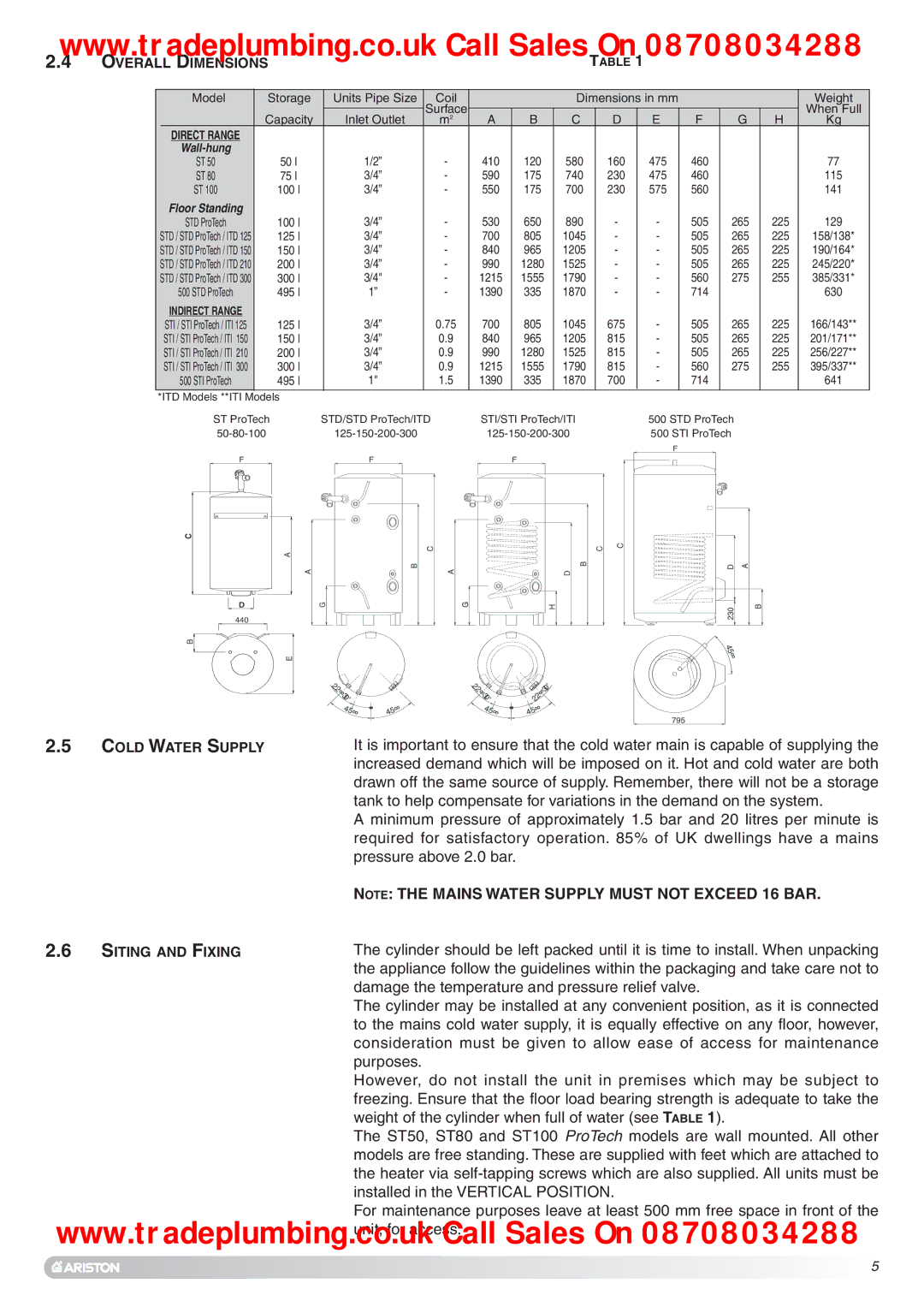

2.4 | OVERALL DIMENSIONS |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| TABLE 1 |

|

|

|

|

|

| |||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||||||||||||

|

| Model |

|

| Storage | Units Pipe Size | Coil |

|

|

|

|

|

|

|

|

| Dimensions in mm |

|

|

|

| Weight | |||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Surface |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| When Full |

|

|

|

|

|

|

|

| Capacity |

|

| Inlet Outlet | m2 |

|

| A |

| B | C |

| D |

| E | F |

| G | H | Kg | ||||||||||||||||

|

| DIRECT RANGE |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||

|

|

|

|

|

|

| 50 l |

|

|

|

|

| 1/2” | - |

| 410 | 120 |

| 580 |

| 160 |

| 475 | 460 |

|

|

| 77 | |||||||||||||||

|

| ST 50 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||||||||||||||||||||||

|

| ST 80 |

|

|

|

| 75 l |

|

|

|

|

| 3/4” | - |

| 590 | 175 |

| 740 |

| 230 |

| 475 | 460 |

|

|

| 115 | |||||||||||||||

|

| ST 100 |

|

|

|

| 100 l |

|

|

|

|

| 3/4” | - |

| 550 | 175 |

| 700 |

| 230 |

| 575 | 560 |

|

|

| 141 | |||||||||||||||

|

| Floor Standing |

|

|

|

| 100 l |

|

|

|

|

| 3/4” | - |

| 530 | 650 |

| 890 |

| - |

| - | 505 |

| 265 | 225 | 129 | |||||||||||||||

|

| STD ProTech |

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||||||||||||||||||||||||

|

| STD / STD ProTech / ITD 125 |

|

|

|

| 125 l |

|

|

|

|

| 3/4” | - |

| 700 | 805 |

| 1045 |

| - |

| - | 505 |

| 265 | 225 | 158/138* | |||||||||||||||

|

| STD / STD ProTech / ITD 150 |

|

|

|

| 150 l |

|

|

|

|

| 3/4” | - |

| 840 | 965 |

| 1205 |

| - |

| - | 505 |

| 265 | 225 | 190/164* | |||||||||||||||

|

| STD / STD ProTech / ITD 210 |

|

|

|

| 200 l |

|

|

|

|

| 3/4” | - |

| 990 | 1280 | 1525 |

| - |

| - | 505 |

| 265 | 225 | 245/220* | ||||||||||||||||

|

| STD / STD ProTech / ITD 300 |

|

|

|

| 300 l | 3/4" |

|

|

|

| - |

| 1215 | 1555 | 1790 |

| - |

| - | 560 |

| 275 | 255 | 385/331* | |||||||||||||||||

|

| 500 STD ProTech |

|

|

|

| 495 l |

|

|

|

|

| 1” | - |

| 1390 | 335 |

| 1870 |

| - |

| - | 714 |

|

|

| 630 | |||||||||||||||

|

| INDIRECT RANGE |

|

|

|

| 125 l |

|

|

|

|

| 3/4” | 0.75 |

| 700 | 805 |

| 1045 |

| 675 |

| - | 505 |

| 265 | 225 | 166/143** | |||||||||||||||

|

| STI / STI ProTech / ITI 125 |

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||||||||||||||||||||||||

|

| STI / STI ProTech / ITI 150 |

|

|

|

| 150 l |

|

|

|

|

| 3/4” | 0.9 |

| 840 | 965 |

| 1205 |

| 815 |

| - | 505 |

| 265 | 225 | 201/171** | |||||||||||||||

|

| STI / STI ProTech / ITI 210 |

|

|

|

| 200 l |

|

|

|

|

| 3/4” | 0.9 |

| 990 | 1280 | 1525 |

| 815 |

| - | 505 |

| 265 | 225 | 256/227** | ||||||||||||||||

|

| STI / STI ProTech / ITI 300 |

|

|

|

| 300 l |

|

|

|

|

| 3/4” | 0.9 |

| 1215 | 1555 | 1790 |

| 815 |

| - | 560 |

| 275 | 255 | 395/337** | ||||||||||||||||

|

| 500 STI ProTech |

|

|

|

| 495 l | 1" |

|

|

|

| 1.5 |

| 1390 | 335 |

| 1870 |

| 700 |

| - | 714 |

|

|

| 641 | ||||||||||||||||

|

| *ITD Models **ITI Models |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||||||||||||||||||||||||

|

|

| ST ProTech | STD/STD ProTech/ITD | STI/STI ProTech/ITI |

|

|

| 500 STD ProTech |

|

| ||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

| 500 STI ProTech |

|

|

| ||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

It is important to ensure that the cold water main is capable of supplying the increased demand which will be imposed on it. Hot and cold water are both drawn off the same source of supply. Remember, there will not be a storage tank to help compensate for variations in the demand on the system.

A minimum pressure of approximately 1.5 bar and 20 litres per minute is required for satisfactory operation. 85% of UK dwellings have a mains pressure above 2.0 bar.

NOTE: THE MAINS WATER SUPPLY MUST NOT EXCEED 16 BAR.

The cylinder should be left packed until it is time to install. When unpacking the appliance follow the guidelines within the packaging and take care not to damage the temperature and pressure relief valve.

The cylinder may be installed at any convenient position, as it is connected to the mains cold water supply, it is equally effective on any floor, however, consideration must be given to allow ease of access for maintenance purposes.

However, do not install the unit in premises which may be subject to freezing. Ensure that the floor load bearing strength is adequate to take the weight of the cylinder when full of water (see TABLE 1).

The ST50, ST80 and ST100 ProTech models are wall mounted. All other models are free standing. These are supplied with feet which are attached to the heater via

For maintenance purposes leave at least 500 mm free space in front of the

www.tradeplumbing.unit,cofor.ukaccessCall. Sales On 08708034288

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]() 5

5