Rev. A.5, 8/03 | Page- 3 |

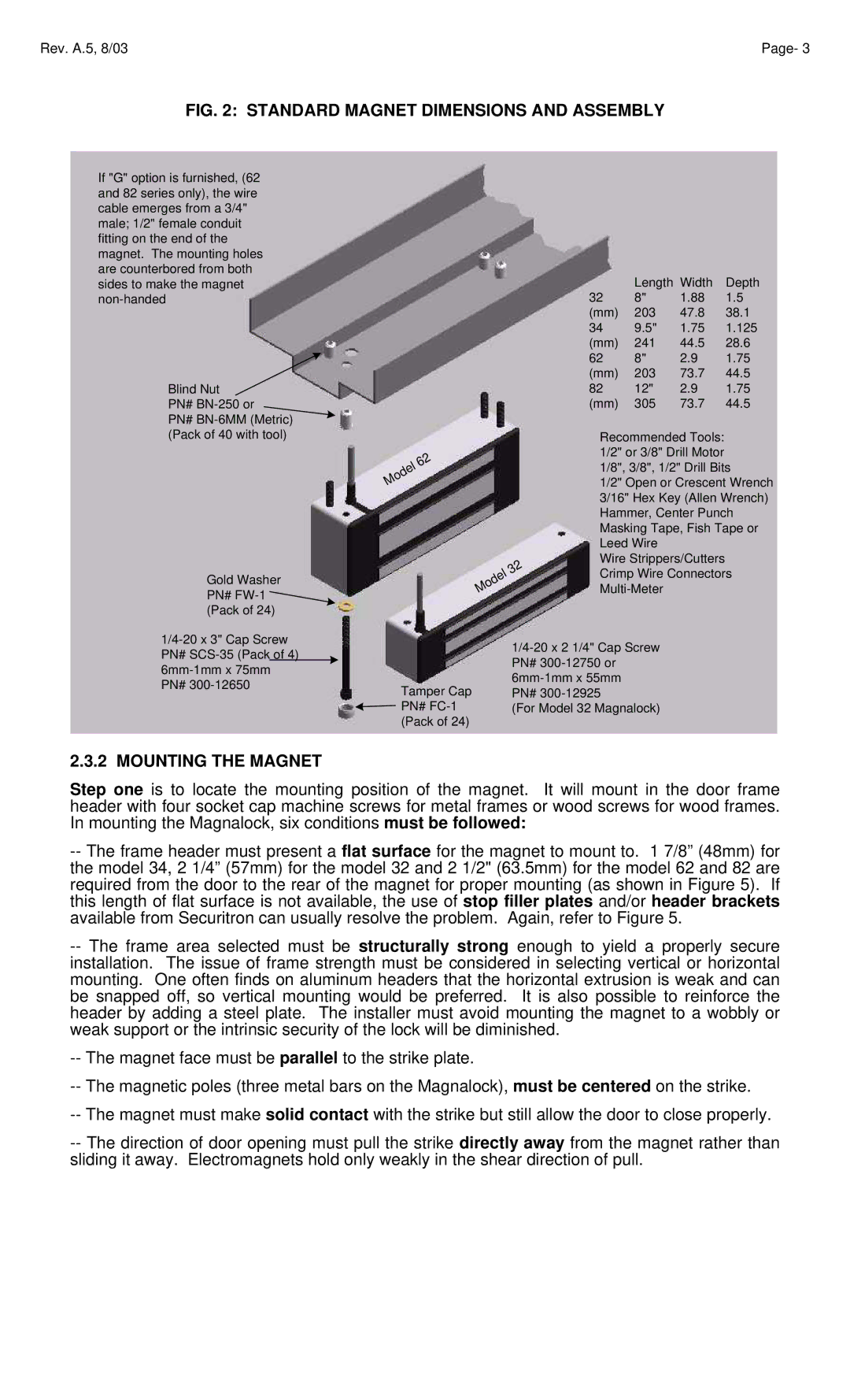

FIG. 2: STANDARD MAGNET DIMENSIONS AND ASSEMBLY

If "G" option is furnished, (62 and 82 series only), the wire cable emerges from a 3/4" male; 1/2" female conduit fitting on the end of the magnet. The mounting holes are counterbored from both sides to make the magnet

Blind Nut

PN#

PN#

Gold Washer PN# ![]() (Pack of 24)

(Pack of 24)

|

|

|

| 2 |

|

|

| 6 | |

|

|

| l |

|

|

| e |

| |

| d |

|

| |

o |

|

|

| |

M |

|

|

|

|

|

|

|

| 2 |

|

|

| 3 | |

|

|

| l |

|

|

| e |

| |

| d |

|

| |

o |

|

|

| |

M |

|

|

|

|

| Length | Width | Depth |

32 | 8" | 1.88 | 1.5 |

(mm) | 203 | 47.8 | 38.1 |

34 | 9.5" | 1.75 | 1.125 |

(mm) | 241 | 44.5 | 28.6 |

62 | 8" | 2.9 | 1.75 |

(mm) | 203 | 73.7 | 44.5 |

82 | 12" | 2.9 | 1.75 |

(mm) | 305 | 73.7 | 44.5 |

Recommended Tools: 1/2" or 3/8" Drill Motor 1/8", 3/8", 1/2" Drill Bits

1/2" Open or Crescent Wrench 3/16" Hex Key (Allen Wrench) Hammer, Center Punch Masking Tape, Fish Tape or Leed Wire

Wire Strippers/Cutters

Crimp Wire Connectors

| |

| PN# |

Tamper Cap | |

PN# | |

PN# | (For Model 32 Magnalock) |

(Pack of 24) |

|

2.3.2 MOUNTING THE MAGNET

Step one is to locate the mounting position of the magnet. It will mount in the door frame header with four socket cap machine screws for metal frames or wood screws for wood frames. In mounting the Magnalock, six conditions must be followed:

--The frame header must present a flat surface for the magnet to mount to. 1 7/8” (48mm) for the model 34, 2 1/4” (57mm) for the model 32 and 2 1/2" (63.5mm) for the model 62 and 82 are required from the door to the rear of the magnet for proper mounting (as shown in Figure 5). If this length of flat surface is not available, the use of stop filler plates and/or header brackets available from Securitron can usually resolve the problem. Again, refer to Figure 5.

--The frame area selected must be structurally strong enough to yield a properly secure installation. The issue of frame strength must be considered in selecting vertical or horizontal mounting. One often finds on aluminum headers that the horizontal extrusion is weak and can be snapped off, so vertical mounting would be preferred. It is also possible to reinforce the header by adding a steel plate. The installer must avoid mounting the magnet to a wobbly or weak support or the intrinsic security of the lock will be diminished.

--The magnet face must be parallel to the strike plate.

--The magnetic poles (three metal bars on the Magnalock), must be centered on the strike.

--The magnet must make solid contact with the strike but still allow the door to close properly.

--The direction of door opening must pull the strike directly away from the magnet rather than sliding it away. Electromagnets hold only weakly in the shear direction of pull.