9.2. MAINTENANCE AT THE END OF THE WORKING DAY

9.2.1.Disconnect electric and pneumatic connections. (Main Switch must be on “0” position)

9.2.2.Remove all burr, chip and foreign materials from the machine surfaces. If it is necessary to clean the inside of the blade guard, remove the front cover, use gloves to protect your hands from the sharp edges of the blade.

9.2.3.If water or water based liquids were used during cutting, dry the machine with a dry cloth after the operation is finished.

9.2.4.Apply a thin layer of machine oil to protect the table against corrosion. If the machine will not be used for a long time, lubricate with a protective oil.

9.2.5.Don’t use materials for cleaning the machine, which could damage its paint.

9.2.6.Lubricate both surfaces of the saw blade with machine oil in order to protect it against corrosion.

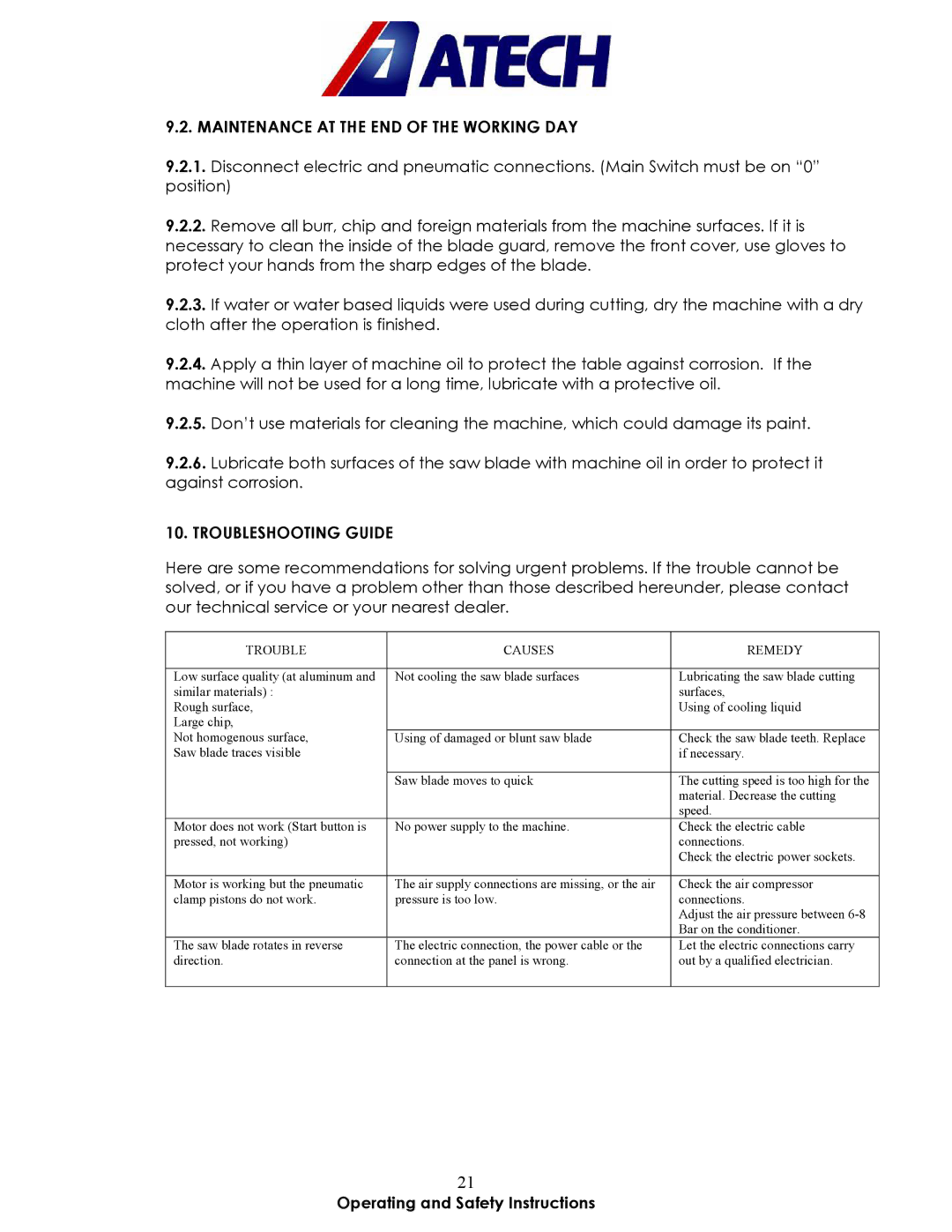

10. TROUBLESHOOTING GUIDE

Here are some recommendations for solving urgent problems. If the trouble cannot be solved, or if you have a problem other than those described hereunder, please contact our technical service or your nearest dealer.

TROUBLE | CAUSES | REMEDY |

|

|

|

Low surface quality (at aluminum and | Not cooling the saw blade surfaces | Lubricating the saw blade cutting |

similar materials) : |

| surfaces, |

Rough surface, |

| Using of cooling liquid |

Large chip, |

|

|

Not homogenous surface, | Using of damaged or blunt saw blade | Check the saw blade teeth. Replace |

Saw blade traces visible |

| if necessary. |

|

|

|

| Saw blade moves to quick | The cutting speed is too high for the |

|

| material. Decrease the cutting |

|

| speed. |

Motor does not work (Start button is | No power supply to the machine. | Check the electric cable |

pressed, not working) |

| connections. |

|

| Check the electric power sockets. |

|

|

|

Motor is working but the pneumatic | The air supply connections are missing, or the air | Check the air compressor |

clamp pistons do not work. | pressure is too low. | connections. |

|

| Adjust the air pressure between |

|

| Bar on the conditioner. |

The saw blade rotates in reverse | The electric connection, the power cable or the | Let the electric connections carry |

direction. | connection at the panel is wrong. | out by a qualified electrician. |

|

|

|

21