Tank (Nipple) Mounted

The BR9235™ MRV can be

Bracket (Chassis) Mounted

The BR9235™ MRV provides an option with a bracket for frame mounting directly to the trailer frame rail or crossmember. It is recommended to use two Grade 5, 3/8‑16 bolts, torqued to 180 – 220

J1708/J1587 DIAGNOSTIC LINK

The Premium

Ignition power must be provided to the

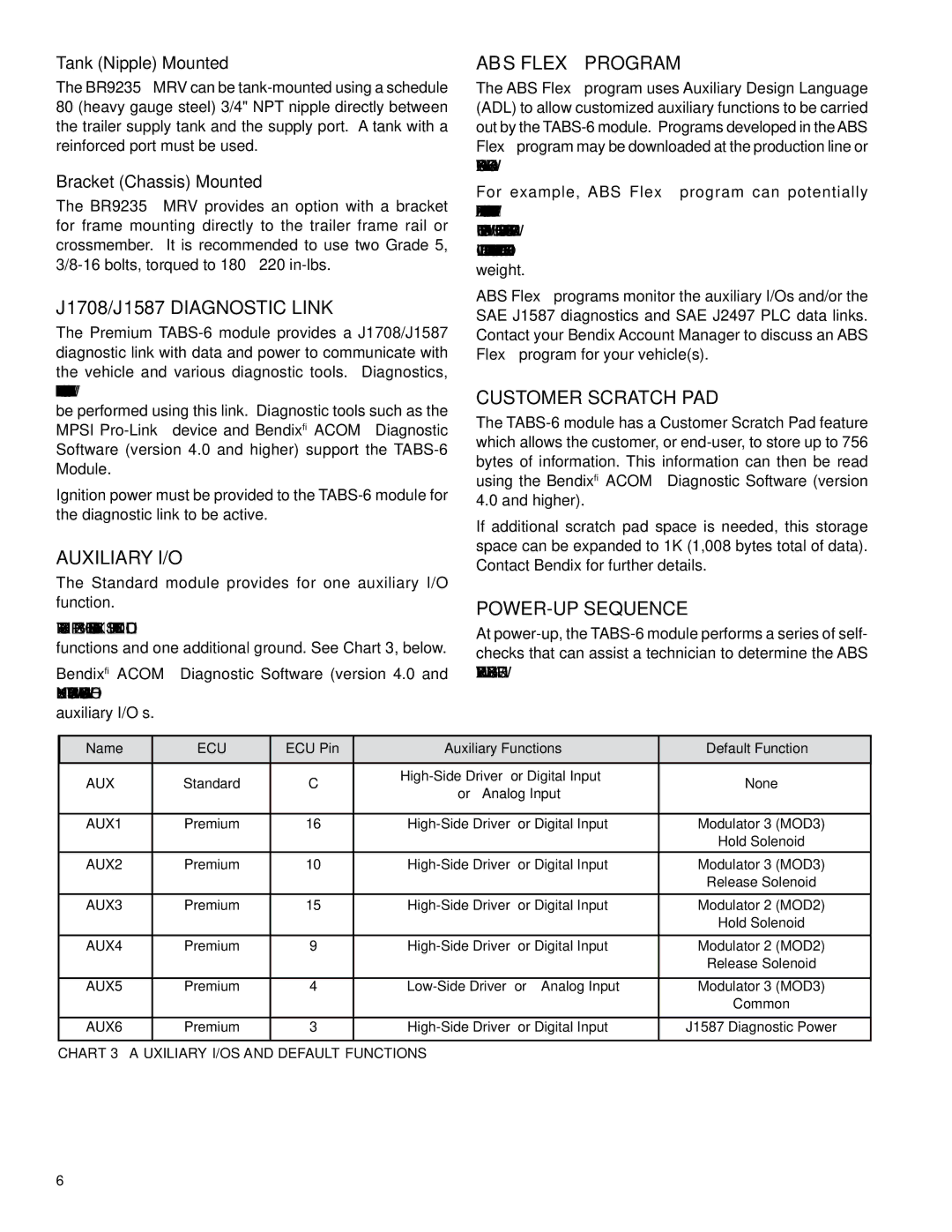

AUXILIARY I/O

The Standard module provides for one auxiliary I/O function.

The Premium module provides for up to five auxiliary functions and one additional ground. See Chart 3, below.

Bendix® ACOM™ Diagnostic Software (version 4.0 and higher) supports the configuration of the

auxiliary I/O’s.

ABs Flex™ Program

The ABS Flex™ program uses Auxiliary Design Language (ADL) to allow customized auxiliary functions to be carried out by the

For example, ABS Flex™ program can potentially communicate the status of: tire inflation and/or temperature; reefer temperature; load presence; slider pin position; lift axle position; proximity/reverse alarm; and vehicle weight.

ABS Flex™ programs monitor the auxiliary I/Os and/or the SAE J1587 diagnostics and SAE J2497 PLC data links. Contact your Bendix Account Manager to discuss an ABS Flex™ program for your vehicle(s).

CUSTOMER SCRATCH PAD

The

If additional scratch pad space is needed, this storage space can be expanded to 1K (1,008 bytes total of data). Contact Bendix for further details.

POWER-UP SEQUENCE

At

Name | ECU | ECU Pin | Auxiliary Functions | Default Function | |

AUX | Standard | C | • | None | |

or • Analog Input | |||||

|

|

|

| ||

|

|

|

|

| |

AUX1 | Premium | 16 | • | Modulator 3 (MOD3) | |

|

|

|

| Hold Solenoid | |

AUX2 | Premium | 10 | • | Modulator 3 (MOD3) | |

|

|

|

| Release Solenoid | |

|

|

|

|

| |

AUX3 | Premium | 15 | • | Modulator 2 (MOD2) | |

|

|

|

| Hold Solenoid | |

|

|

|

|

| |

AUX4 | Premium | 9 | • | Modulator 2 (MOD2) | |

|

|

|

| Release Solenoid | |

|

|

|

|

| |

AUX5 | Premium | 4 | • | Modulator 3 (MOD3) | |

|

|

|

| Common | |

|

|

|

|

| |

AUX6 | Premium | 3 | • | J1587 Diagnostic Power | |

|

|

|

|

|

CHART 3 – Auxiliary I/Os and Default Functions