LEFT SIDE ![]()

![]()

![]()

![]() BEVEL STOP

BEVEL STOP![]()

![]()

![]()

![]() SCREW

SCREW ![]()

![]()

![]()

![]()

![]()

![]()

LEFT SIDE FENCE CLAMPING ![]() KNOBS

KNOBS![]()

![]()

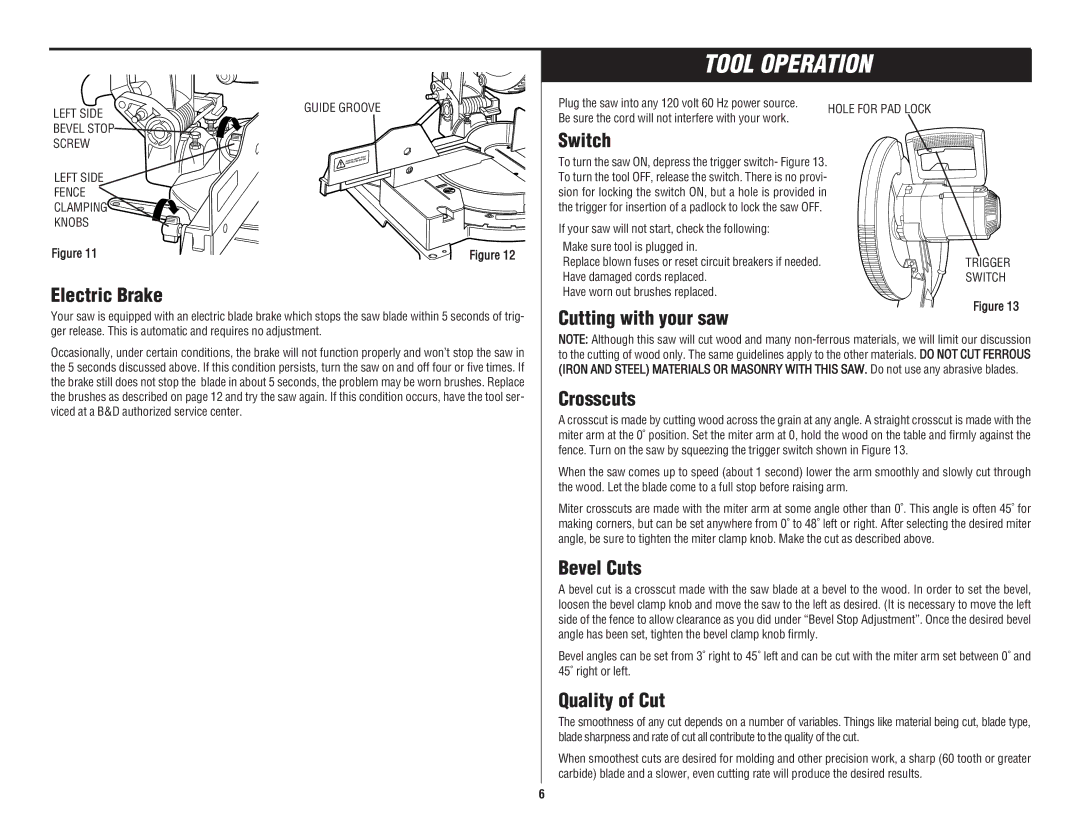

Figure 11

GUIDE GROOVE

ADJU | ST FENCE | |

| E USE | |

ALWAYSLY BEFOR |

| |

PROPER |

|

|

Figure 12

TOOL OPERATION

Plug the saw into any 120 volt 60 Hz power source. | HOLE FOR PAD LOCK | |

Be sure the cord will not interfere with your work. | ||

|

Switch

To turn the saw ON, depress the trigger switch- Figure 13. To turn the tool OFF, release the switch. There is no provi- sion for locking the switch ON, but a hole is provided in the trigger for insertion of a padlock to lock the saw OFF.

If your saw will not start, check the following:

Make sure tool is plugged in. |

|

Replace blown fuses or reset circuit breakers if needed. | TRIGGER |

Have damaged cords replaced. | SWITCH |

Electric Brake

Your saw is equipped with an electric blade brake which stops the saw blade within 5 seconds of trig- ger release. This is automatic and requires no adjustment.

Occasionally, under certain conditions, the brake will not function properly and won’t stop the saw in the 5 seconds discussed above. If this condition persists, turn the saw on and off four or five times. If the brake still does not stop the blade in about 5 seconds, the problem may be worn brushes. Replace the brushes as described on page 12 and try the saw again. If this condition occurs, have the tool ser- viced at a B&D authorized service center.

Have worn out brushes replaced. |

Figure 13 |

Cutting with your saw |

NOTE: Although this saw will cut wood and many

Crosscuts

A crosscut is made by cutting wood across the grain at any angle. A straight crosscut is made with the miter arm at the 0˚ position. Set the miter arm at 0, hold the wood on the table and firmly against the fence. Turn on the saw by squeezing the trigger switch shown in Figure 13.

When the saw comes up to speed (about 1 second) lower the arm smoothly and slowly cut through the wood. Let the blade come to a full stop before raising arm.

Miter crosscuts are made with the miter arm at some angle other than 0˚. This angle is often 45˚ for making corners, but can be set anywhere from 0˚ to 48˚ left or right. After selecting the desired miter angle, be sure to tighten the miter clamp knob. Make the cut as described above.

Bevel Cuts

A bevel cut is a crosscut made with the saw blade at a bevel to the wood. In order to set the bevel, loosen the bevel clamp knob and move the saw to the left as desired. (It is necessary to move the left side of the fence to allow clearance as you did under “Bevel Stop Adjustment”. Once the desired bevel angle has been set, tighten the bevel clamp knob firmly.

Bevel angles can be set from 3˚ right to 45˚ left and can be cut with the miter arm set between 0˚ and 45˚ right or left.

Quality of Cut

The smoothness of any cut depends on a number of variables. Things like material being cut, blade type, blade sharpness and rate of cut all contribute to the quality of the cut.

When smoothest cuts are desired for molding and other precision work, a sharp (60 tooth or greater carbide) blade and a slower, even cutting rate will produce the desired results.

6