When bevel cutting, the holddown (B) Fig. 31, can be adjusted to lay flat on the stock by loosening screw (C) and tilting the holddown (B) accordingly. Then tighten screw (C).

ADJUSTING THE TABLE

1.Loosen the table locking handle, and move the table all the way to the right.

2.Using a square (A) Fig. 32, check to see if the table is 90 degrees to the saw blade, as shown.

3.If the table is not at 90 degrees to the blade, adjust the table accordingly making certain screw (B) Fig. 33, contacts bottom of table surface when table is 90 degrees to the blade. Screw (B) can be adjusted by loosening nut (C), thread screw (B) in or out the desired distance and tighten nut (C).

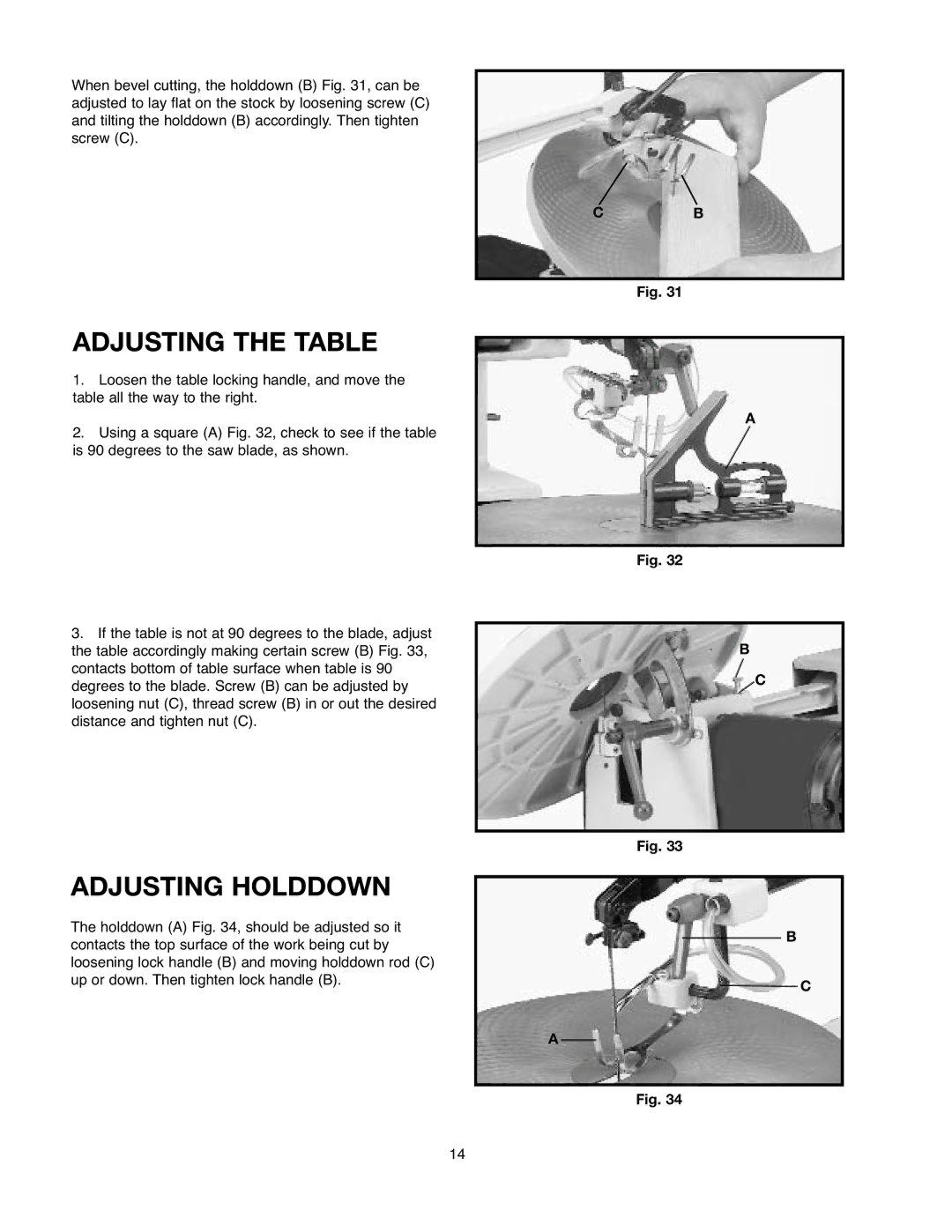

ADJUSTING HOLDDOWN

The holddown (A) Fig. 34, should be adjusted so it contacts the top surface of the work being cut by loosening lock handle (B) and moving holddown rod (C) up or down. Then tighten lock handle (B).

CB

Fig. 31

A

Fig. 32

B

C

Fig. 33

B

C

A

Fig. 34

14