STEP 2. Adjust the bevel stops

CAUTION: Turn off and unplug saw.

CAUTION: Turn off and unplug saw.

1.Loosen the bevel lock handle and turn the bevel angle handwheel clockwise until it stops.

2.Raise the blade to its highest position and lift the blade guard.

3.Check blade angle with a combination square from left side of the blade, keeping the square against the flat part of the blade and not touching the teeth or table insert.

4.If blade angle is wrong, turn the 90° stop screw (located to the left of the blade looking from the front) 1 time counterclockwise with a 4mm hex wrench.

5.Turn handwheel until blade is 90° to the tabletop as indicated with a square.

6.Turn 90° stop screw (left of blade) clockwise till slight resistance is felt.

NOTE: DO NOT OVERTIGHTEN.

7.Check the 45° setting. Tilt the blade with the bevel handwheel as far as it will go to the left. Place square against the blade (be sure the square is not against one of the saw teeth). If the blade is not at 45°, unscrew the 45° stop screw (right of blade) turn handwheel 1 turn clockwise, then crank wheel counterclockwise to bring blade to 45° setting and tighten the screw. Recheck and repeat if necessary.

STEP 3. Bevel Pointer Adjustment

If bevel pointer does not point to “0”, when blade is at 90° to the table top, loosen the point- er screw with a phillips screwdriver. (The screw is accessible through the handwheel and the curved slot in front of the saw.) Set the pointer to “0” and retighten the pointer screw.

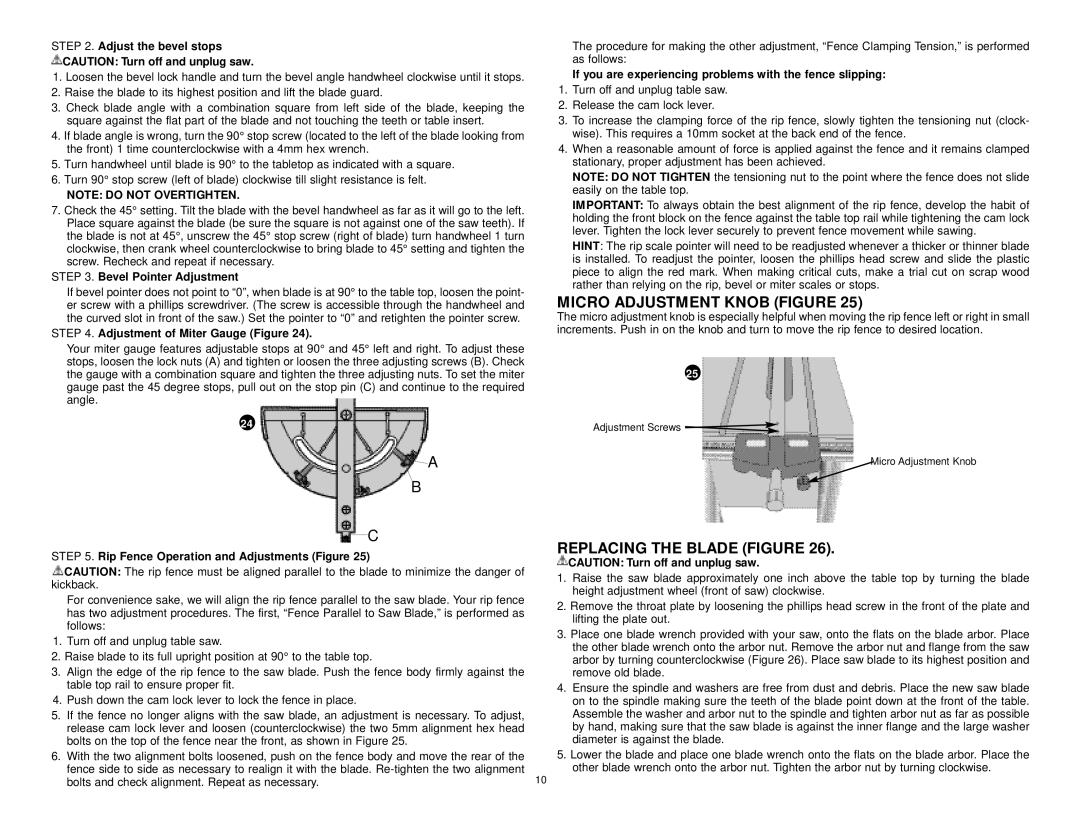

STEP 4. Adjustment of Miter Gauge (Figure 24).

Your miter gauge features adjustable stops at 90° and 45° left and right. To adjust these stops, loosen the lock nuts (A) and tighten or loosen the three adjusting screws (B). Check the gauge with a combination square and tighten the three adjusting nuts. To set the miter gauge past the 45 degree stops, pull out on the stop pin (C) and continue to the required angle.

24

A

B

C

STEP 5. Rip Fence Operation and Adjustments (Figure 25)

CAUTION: The rip fence must be aligned parallel to the blade to minimize the danger of kickback.

CAUTION: The rip fence must be aligned parallel to the blade to minimize the danger of kickback.

For convenience sake, we will align the rip fence parallel to the saw blade. Your rip fence has two adjustment procedures. The first, “Fence Parallel to Saw Blade,” is performed as follows:

1.Turn off and unplug table saw.

2.Raise blade to its full upright position at 90° to the table top.

3.Align the edge of the rip fence to the saw blade. Push the fence body firmly against the table top rail to ensure proper fit.

4.Push down the cam lock lever to lock the fence in place.

5.If the fence no longer aligns with the saw blade, an adjustment is necessary. To adjust, release cam lock lever and loosen (counterclockwise) the two 5mm alignment hex head bolts on the top of the fence near the front, as shown in Figure 25.

6.With the two alignment bolts loosened, push on the fence body and move the rear of the fence side to side as necessary to realign it with the blade. Re-tighten the two alignment

bolts and check alignment. Repeat as necessary. | 10 |

The procedure for making the other adjustment, “Fence Clamping Tension,” is performed as follows:

If you are experiencing problems with the fence slipping:

1.Turn off and unplug table saw.

2.Release the cam lock lever.

3.To increase the clamping force of the rip fence, slowly tighten the tensioning nut (clock- wise). This requires a 10mm socket at the back end of the fence.

4.When a reasonable amount of force is applied against the fence and it remains clamped stationary, proper adjustment has been achieved.

NOTE: DO NOT TIGHTEN the tensioning nut to the point where the fence does not slide easily on the table top.

IMPORTANT: To always obtain the best alignment of the rip fence, develop the habit of holding the front block on the fence against the table top rail while tightening the cam lock lever. Tighten the lock lever securely to prevent fence movement while sawing.

HINT: The rip scale pointer will need to be readjusted whenever a thicker or thinner blade is installed. To readjust the pointer, loosen the phillips head screw and slide the plastic piece to align the red mark. When making critical cuts, make a trial cut on scrap wood rather than relying on the rip, bevel or miter scales or stops.

MICRO ADJUSTMENT KNOB (FIGURE 25)

The micro adjustment knob is especially helpful when moving the rip fence left or right in small increments. Push in on the knob and turn to move the rip fence to desired location.

25

Adjustment Screws

Micro Adjustment Knob

REPLACING THE BLADE (FIGURE 26).

CAUTION: Turn off and unplug saw.

CAUTION: Turn off and unplug saw.

1.Raise the saw blade approximately one inch above the table top by turning the blade height adjustment wheel (front of saw) clockwise.

2.Remove the throat plate by loosening the phillips head screw in the front of the plate and lifting the plate out.

3.Place one blade wrench provided with your saw, onto the flats on the blade arbor. Place the other blade wrench onto the arbor nut. Remove the arbor nut and flange from the saw arbor by turning counterclockwise (Figure 26). Place saw blade to its highest position and remove old blade.

4.Ensure the spindle and washers are free from dust and debris. Place the new saw blade on to the spindle making sure the teeth of the blade point down at the front of the table. Assemble the washer and arbor nut to the spindle and tighten arbor nut as far as possible by hand, making sure that the saw blade is against the inner flange and the large washer diameter is against the blade.

5.Lower the blade and place one blade wrench onto the flats on the blade arbor. Place the other blade wrench onto the arbor nut. Tighten the arbor nut by turning clockwise.