6.NOTE: Different types of blades make different kerfs (width of cuts). Therefore, it is nec- essary to check adjustment of rip fence pointer and blade guard splitter when changing blades.

26

LEVELING THE SAW

The saw can be leveled by loosening the bolts on the back legs and sliding the leg up or down slightly and retightening the bolts.

If the saw becomes unstable when cutting oversize or overweight workpieces, stop and secure the saw to the floor. To do this, remove the rubber feet and mount angle brackets to each leg after drilling 5/16” (8mm) diameter holes in each leg 1/4” (6.3mm) minimum from the end. “Angle brackets and mounting hardware to be obtained locally.” Secure brackets to floor using the appropriate wood screws or concrete anchors as required.

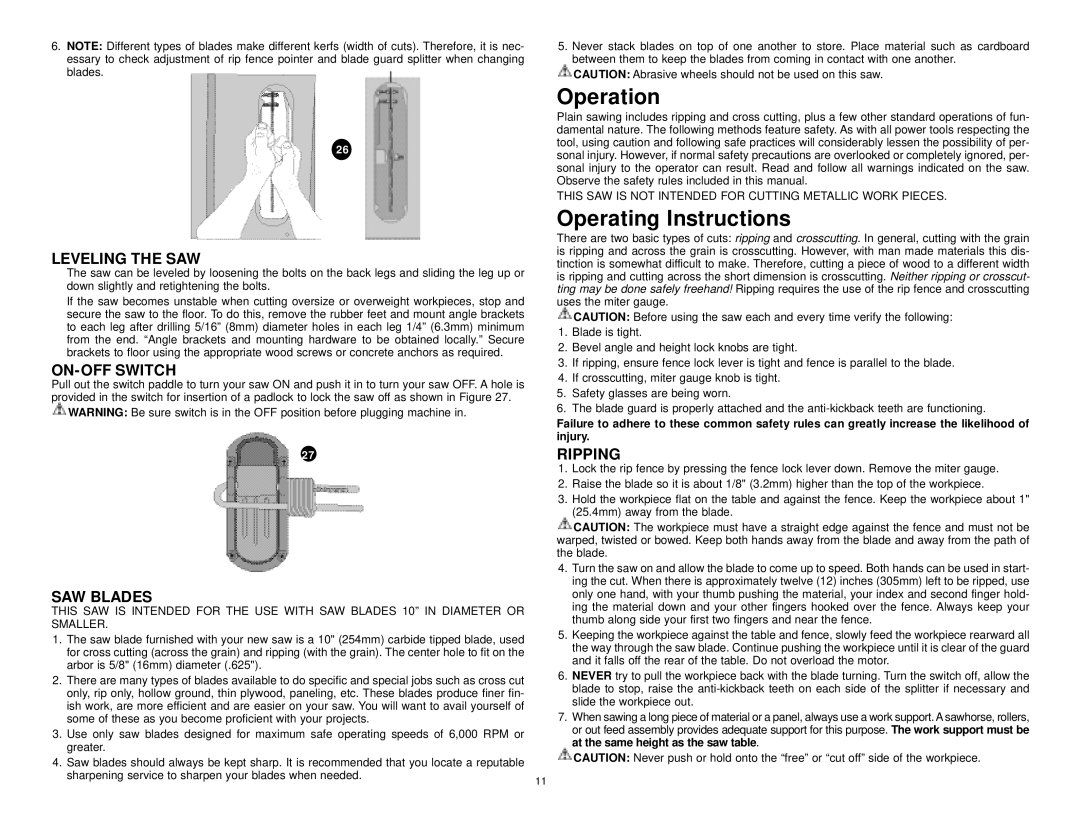

ON-OFF SWITCH

Pull out the switch paddle to turn your saw ON and push it in to turn your saw OFF. A hole is provided in the switch for insertion of a padlock to lock the saw off as shown in Figure 27.

WARNING: Be sure switch is in the OFF position before plugging machine in.

WARNING: Be sure switch is in the OFF position before plugging machine in.

27

SAW BLADES

THIS SAW IS INTENDED FOR THE USE WITH SAW BLADES 10” IN DIAMETER OR SMALLER.

1. The saw blade furnished with your new saw is a 10" (254mm) carbide tipped blade, used for cross cutting (across the grain) and ripping (with the grain). The center hole to fit on the arbor is 5/8" (16mm) diameter (.625").

2. There are many types of blades available to do specific and special jobs such as cross cut only, rip only, hollow ground, thin plywood, paneling, etc. These blades produce finer fin- ish work, are more efficient and are easier on your saw. You will want to avail yourself of some of these as you become proficient with your projects.

3. Use only saw blades designed for maximum safe operating speeds of 6,000 RPM or greater.

4. Saw blades should always be kept sharp. It is recommended that you locate a reputable sharpening service to sharpen your blades when needed.

11

5.Never stack blades on top of one another to store. Place material such as cardboard between them to keep the blades from coming in contact with one another.

CAUTION: Abrasive wheels should not be used on this saw.

CAUTION: Abrasive wheels should not be used on this saw.

Operation

Plain sawing includes ripping and cross cutting, plus a few other standard operations of fun- damental nature. The following methods feature safety. As with all power tools respecting the tool, using caution and following safe practices will considerably lessen the possibility of per- sonal injury. However, if normal safety precautions are overlooked or completely ignored, per- sonal injury to the operator can result. Read and follow all warnings indicated on the saw. Observe the safety rules included in this manual.

THIS SAW IS NOT INTENDED FOR CUTTING METALLIC WORK PIECES.

Operating Instructions

There are two basic types of cuts: ripping and crosscutting. In general, cutting with the grain is ripping and across the grain is crosscutting. However, with man made materials this dis- tinction is somewhat difficult to make. Therefore, cutting a piece of wood to a different width is ripping and cutting across the short dimension is crosscutting. Neither ripping or crosscut- ting may be done safely freehand! Ripping requires the use of the rip fence and crosscutting uses the miter gauge.

CAUTION: Before using the saw each and every time verify the following:

CAUTION: Before using the saw each and every time verify the following:

1.Blade is tight.

2.Bevel angle and height lock knobs are tight.

3.If ripping, ensure fence lock lever is tight and fence is parallel to the blade.

4.If crosscutting, miter gauge knob is tight.

5.Safety glasses are being worn.

6.The blade guard is properly attached and the anti-kickback teeth are functioning.

Failure to adhere to these common safety rules can greatly increase the likelihood of injury.

RIPPING

1.Lock the rip fence by pressing the fence lock lever down. Remove the miter gauge.

2.Raise the blade so it is about 1/8" (3.2mm) higher than the top of the workpiece.

3.Hold the workpiece flat on the table and against the fence. Keep the workpiece about 1" (25.4mm) away from the blade.

CAUTION: The workpiece must have a straight edge against the fence and must not be warped, twisted or bowed. Keep both hands away from the blade and away from the path of the blade.

CAUTION: The workpiece must have a straight edge against the fence and must not be warped, twisted or bowed. Keep both hands away from the blade and away from the path of the blade.

4.Turn the saw on and allow the blade to come up to speed. Both hands can be used in start- ing the cut. When there is approximately twelve (12) inches (305mm) left to be ripped, use only one hand, with your thumb pushing the material, your index and second finger hold- ing the material down and your other fingers hooked over the fence. Always keep your thumb along side your first two fingers and near the fence.

5.Keeping the workpiece against the table and fence, slowly feed the workpiece rearward all the way through the saw blade. Continue pushing the workpiece until it is clear of the guard and it falls off the rear of the table. Do not overload the motor.

6.NEVER try to pull the workpiece back with the blade turning. Turn the switch off, allow the blade to stop, raise the anti-kickback teeth on each side of the splitter if necessary and slide the workpiece out.

7.When sawing a long piece of material or a panel, always use a work support. A sawhorse, rollers, or out feed assembly provides adequate support for this purpose. The work support must be at the same height as the saw table.

CAUTION: Never push or hold onto the “free” or “cut off” side of the workpiece.

CAUTION: Never push or hold onto the “free” or “cut off” side of the workpiece.