DRAIN CONNECTIONS

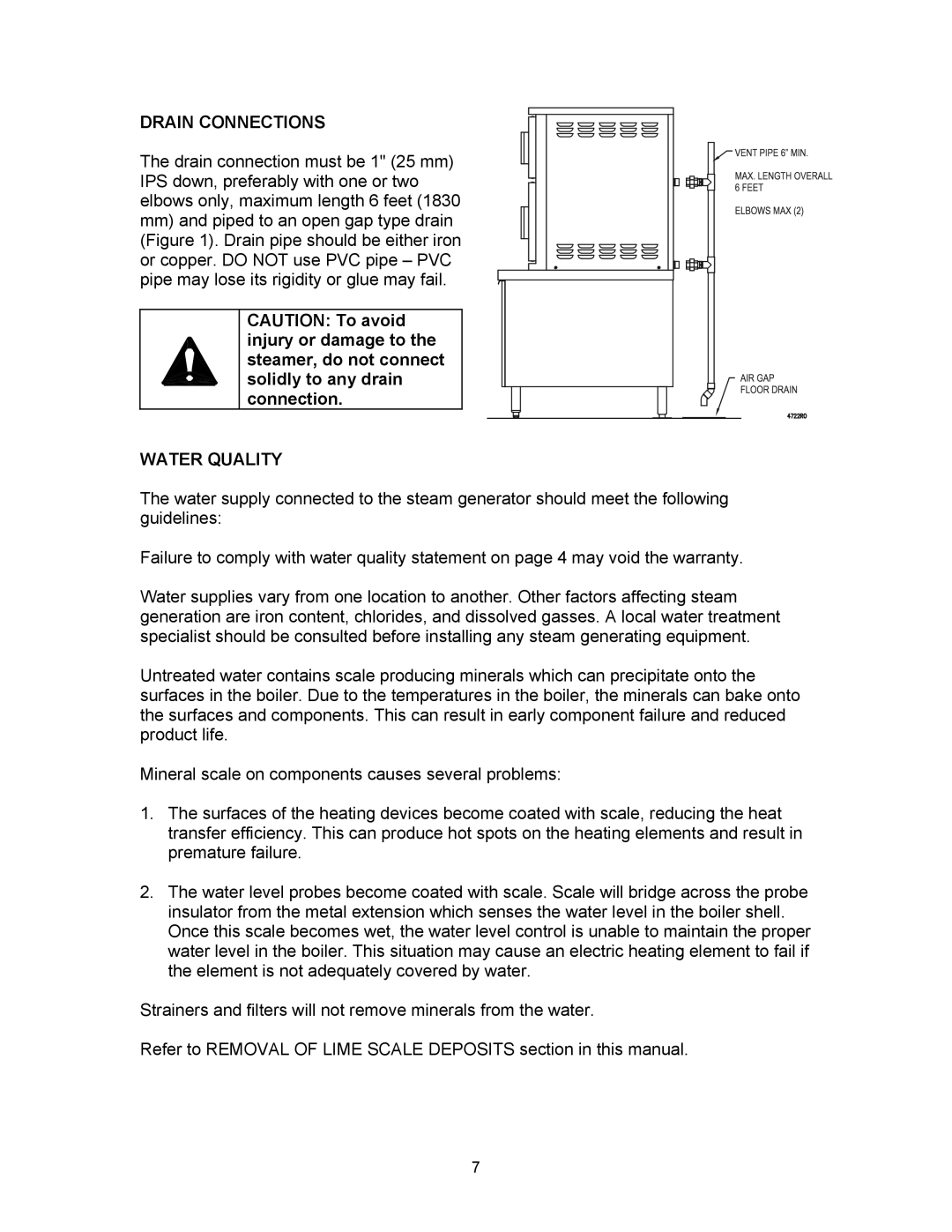

The drain connection must be 1" (25 mm) IPS down, preferably with one or two elbows only, maximum length 6 feet (1830 mm) and piped to an open gap type drain (Figure 1). Drain pipe should be either iron or copper. DO NOT use PVC pipe – PVC pipe may lose its rigidity or glue may fail.

CAUTION: To avoid injury or damage to the steamer, do not connect solidly to any drain connection.

WATER QUALITY

The water supply connected to the steam generator should meet the following guidelines:

Failure to comply with water quality statement on page 4 may void the warranty.

Water supplies vary from one location to another. Other factors affecting steam generation are iron content, chlorides, and dissolved gasses. A local water treatment specialist should be consulted before installing any steam generating equipment.

Untreated water contains scale producing minerals which can precipitate onto the surfaces in the boiler. Due to the temperatures in the boiler, the minerals can bake onto the surfaces and components. This can result in early component failure and reduced product life.

Mineral scale on components causes several problems:

1.The surfaces of the heating devices become coated with scale, reducing the heat transfer efficiency. This can produce hot spots on the heating elements and result in premature failure.

2.The water level probes become coated with scale. Scale will bridge across the probe insulator from the metal extension which senses the water level in the boiler shell. Once this scale becomes wet, the water level control is unable to maintain the proper water level in the boiler. This situation may cause an electric heating element to fail if the element is not adequately covered by water.

Strainers and filters will not remove minerals from the water.

Refer to REMOVAL OF LIME SCALE DEPOSITS section in this manual.

7