BM 2609140574 08-08 9/3/08 8:40 AM Page 6

Scanning in Metal-Detection Mode

PRELIMINARY METAL SCAN | ZOOM METAL SCAN |

When scanning for metal objects, press the metal detection mode button 6. The metal detection mode indicator c is indicated in the display and the illuminated ring 1 lights up green.

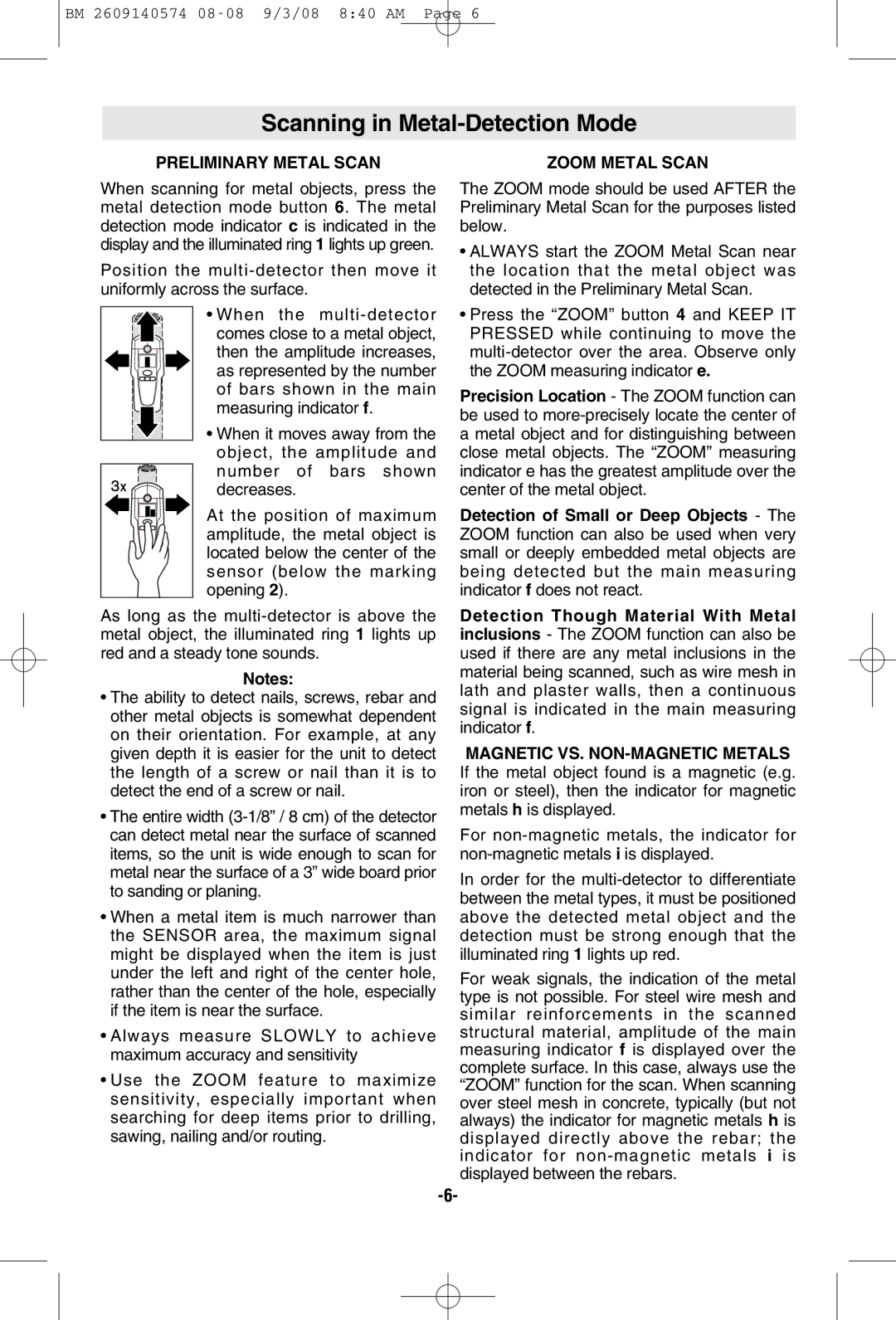

Position the

• When the

• When it moves away from the object, the amplitude and number of bars shown decreases.

At the position of maximum amplitude, the metal object is located below the center of the sensor (below the marking opening 2).

As long as the

Notes:

•The ability to detect nails, screws, rebar and other metal objects is somewhat dependent on their orientation. For example, at any given depth it is easier for the unit to detect the length of a screw or nail than it is to detect the end of a screw or nail.

•The entire width

•When a metal item is much narrower than the SENSOR area, the maximum signal might be displayed when the item is just under the left and right of the center hole, rather than the center of the hole, especially if the item is near the surface.

•Always measure SLOWLY to achieve maximum accuracy and sensitivity

•Use the ZOOM feature to maximize sensitivity, especially important when searching for deep items prior to drilling, sawing, nailing and/or routing.

The ZOOM mode should be used AFTER the Preliminary Metal Scan for the purposes listed below.

•ALWAYS start the ZOOM Metal Scan near the location that the metal object was detected in the Preliminary Metal Scan.

•Press the “ZOOM” button 4 and KEEP IT PRESSED while continuing to move the

Precision Location - The ZOOM function can be used to

Detection of Small or Deep Objects - The ZOOM function can also be used when very small or deeply embedded metal objects are being detected but the main measuring indicator f does not react.

Detection Though Material With Metal inclusions - The ZOOM function can also be used if there are any metal inclusions in the material being scanned, such as wire mesh in lath and plaster walls, then a continuous signal is indicated in the main measuring indicator f.

MAGNETIC VS.

For

In order for the

For weak signals, the indication of the metal type is not possible. For steel wire mesh and similar reinforcements in the scanned structural material, amplitude of the main measuring indicator f is displayed over the complete surface. In this case, always use the “ZOOM” function for the scan. When scanning over steel mesh in concrete, typically (but not always) the indicator for magnetic metals h is displayed directly above the rebar; the indicator for