In this case, bring the tool to the level position and wait for the

In case of ground vibrations or position changes during operation, the tool is automatically leveled in again. To avoid errors by moving the tool, check the position of the laser beams with regard to the reference points upon

Working Advice

Always use the center of the laser point for marking. The size of the laser point changes

with the distance.

Leveling Accuracy

Influences on Accuracy

The ambient temperature has the greatest influence. Especially temperature differences occurring from the ground upward can divert the laser beam.

As thermal fluctuation is largest close to the ground, the tool, if possible, should be mounted on a commercially available tripod and placed in the center of the working area.

Apart from exterior influences,

Should the tool exceed the maximum deviation during one of the tests, see recalibration procedure or have it recalibrated by a Bosch

Checking the Vertical Leveling Accuracy

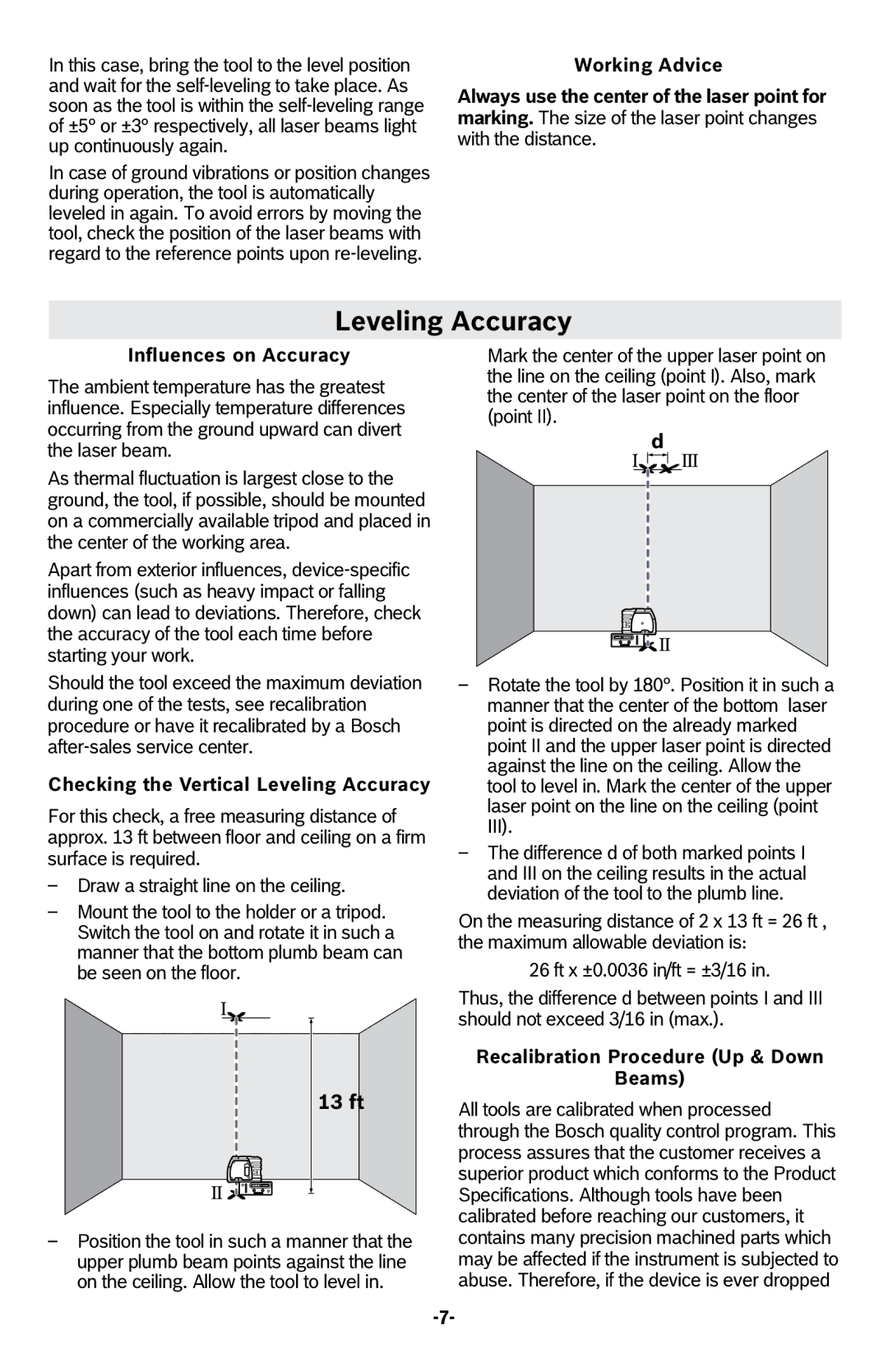

For this check, a free measuring distance of approx. 13 ft between floor and ceiling on a firm surface is required.

–Draw a straight line on the ceiling.

–Mount the tool to the holder or a tripod. Switch the tool on and rotate it in such a manner that the bottom plumb beam can be seen on the floor.

Mark the center of the upper laser point on the line on the ceiling (point I). Also, mark the center of the laser point on the floor (point II).

d

–Rotate the tool by 180°. Position it in such a manner that the center of the bottom laser point is directed on the already marked point II and the upper laser point is directed against the line on the ceiling. Allow the tool to level in. Mark the center of the upper laser point on the line on the ceiling (point III).

–The difference d of both marked points I and III on the ceiling results in the actual deviation of the tool to the plumb line.

On the measuring distance of 2 x 13 ft = 26 ft , the maximum allowable deviation is:

26 ft x ±0.0036 in/ft = ±3/16 in.

Thus, the difference d between points I and III should not exceed 3/16 in (max.).

13 ft

–Position the tool in such a manner that the upper plumb beam points against the line on the ceiling. Allow the tool to level in.

Recalibration Procedure (Up & Down

Beams)

All tools are calibrated when processed through the Bosch quality control program. This process assures that the customer receives a superior product which conforms to the Product Specifications. Although tools have been calibrated before reaching our customers, it contains many precision machined parts which may be affected if the instrument is subjected to abuse. Therefore, if the device is ever dropped