NOTICE: To aid in removal and to prevent breakage of the tee or other fittings:

When removing the fitting(s) from the tank, it may

be necessary to apply heat to the area of the threads.

– USE CAUTION WHEN APPLYING HEAT –

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]() WHEN SPRAYING LACQUER OR OTHER FLAMMABLE LIQUIDS, THERE IS A DANGER OF FIRE OR EXPLOSION. SPRAYING AREA MUST BE

WHEN SPRAYING LACQUER OR OTHER FLAMMABLE LIQUIDS, THERE IS A DANGER OF FIRE OR EXPLOSION. SPRAYING AREA MUST BE

SAFETY VALVE – The safety valve is set to avoid over pressurization of the air tanks. It is present at 140 PSIG and will not function unless tank pressure reaches this pressure. DO NOT ATTEMPT TO ADJUST OR ELIMINATE THIS SAFETY DEVICE.

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]() DO NOT PERFORM WELDING OPERATIONS ON THE AIR TANK OF THIS COMPRESSOR. WELDING ON THE AIR COMPRESSOR TANK CAN SEVERELY IMPAIR TANK STRENGTH AND CAUSE AN EXTREMELY HAZARDOUS CONDITION. WELDING ON THE TANK IN ANY MANNER WILL VOID THE WARRANTY.

DO NOT PERFORM WELDING OPERATIONS ON THE AIR TANK OF THIS COMPRESSOR. WELDING ON THE AIR COMPRESSOR TANK CAN SEVERELY IMPAIR TANK STRENGTH AND CAUSE AN EXTREMELY HAZARDOUS CONDITION. WELDING ON THE TANK IN ANY MANNER WILL VOID THE WARRANTY.

ASSEMBLY | CAP1560 |

1.Remove the air compressor from the box and inspect the unit for any damaged or defective parts. Have any damaged components repaired or replaced before operation.

2.Attach the two wheels using the bolts and nuts provided. Tighten the nuts with a wrench.

3.Attach the front rubber foot pad using the screw, washer, and nut provided. Be careful not to over tighten the bolt.

4.Screw a _" MPT (male pipe thread) quick disconnect air coupler into the air outlet on the regulator. Be sure to wrap the threads of the coupler with Teflon tape to prevent leakage.

5.Attach an airline to the quick disconnect air coupler and your BOSTITCH air compressor is now ready for use.

NOTICE: Use only the recommended extension cord to ensure the proper operation of the air compressor. The use of a

Less than 25 Ft. | 14 Gauge |

25 - 50 Ft. | 12 Gauge |

Longer than 50 Ft. | Not Recommended |

ELECTRICAL GROUNDING INSTRUCTIONS

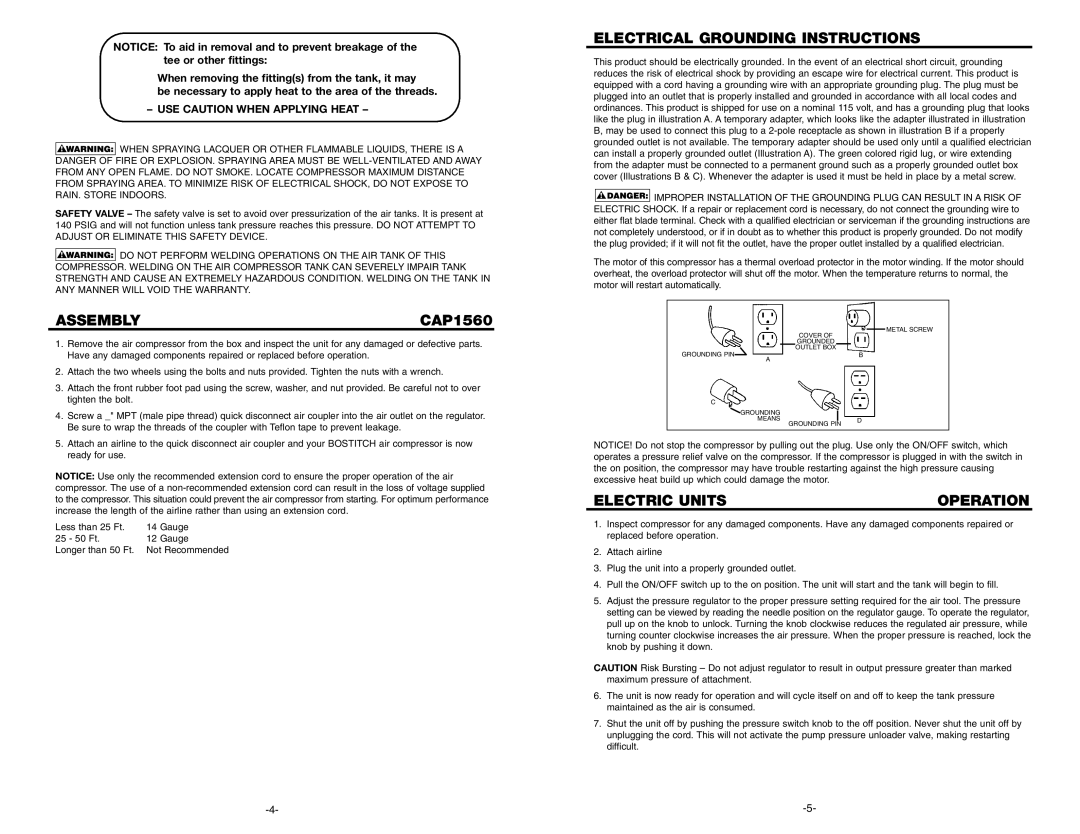

This product should be electrically grounded. In the event of an electrical short circuit, grounding reduces the risk of electrical shock by providing an escape wire for electrical current. This product is equipped with a cord having a grounding wire with an appropriate grounding plug. The plug must be plugged into an outlet that is properly installed and grounded in accordance with all local codes and ordinances. This product is shipped for use on a nominal 115 volt, and has a grounding plug that looks like the plug in illustration A. A temporary adapter, which looks like the adapter illustrated in illustration B, may be used to connect this plug to a

![]()

![]()

![]()

![]()

![]()

![]()

![]() IMPROPER INSTALLATION OF THE GROUNDING PLUG CAN RESULT IN A RISK OF ELECTRIC SHOCK. If a repair or replacement cord is necessary, do not connect the grounding wire to either flat blade terminal. Check with a qualified electrician or serviceman if the grounding instructions are not completely understood, or if in doubt as to whether this product is properly grounded. Do not modify the plug provided; if it will not fit the outlet, have the proper outlet installed by a qualified electrician.

IMPROPER INSTALLATION OF THE GROUNDING PLUG CAN RESULT IN A RISK OF ELECTRIC SHOCK. If a repair or replacement cord is necessary, do not connect the grounding wire to either flat blade terminal. Check with a qualified electrician or serviceman if the grounding instructions are not completely understood, or if in doubt as to whether this product is properly grounded. Do not modify the plug provided; if it will not fit the outlet, have the proper outlet installed by a qualified electrician.

The motor of this compressor has a thermal overload protector in the motor winding. If the motor should overheat, the overload protector will shut off the motor. When the temperature returns to normal, the motor will restart automatically.

METAL SCREW

|

|

| COVER OF |

| ||

|

|

| GROUNDED |

|

| |

GROUNDING PIN |

| OUTLET BOX |

| B | ||

|

|

| ||||

A |

|

|

|

| ||

C |

|

|

|

| ||

GROUNDING |

|

|

|

| ||

|

|

|

| |||

MEANS |

|

|

| D | ||

GROUNDING PIN | ||||||

|

|

| ||||

NOTICE! Do not stop the compressor by pulling out the plug. Use only the ON/OFF switch, which operates a pressure relief valve on the compressor. If the compressor is plugged in with the switch in the on position, the compressor may have trouble restarting against the high pressure causing excessive heat build up which could damage the motor.

ELECTRIC UNITS | OPERATION |

1.Inspect compressor for any damaged components. Have any damaged components repaired or replaced before operation.

2.Attach airline

3.Plug the unit into a properly grounded outlet.

4.Pull the ON/OFF switch up to the on position. The unit will start and the tank will begin to fill.

5.Adjust the pressure regulator to the proper pressure setting required for the air tool. The pressure setting can be viewed by reading the needle position on the regulator gauge. To operate the regulator, pull up on the knob to unlock. Turning the knob clockwise reduces the regulated air pressure, while turning counter clockwise increases the air pressure. When the proper pressure is reached, lock the knob by pushing it down.

CAUTION Risk Bursting – Do not adjust regulator to result in output pressure greater than marked maximum pressure of attachment.

6.The unit is now ready for operation and will cycle itself on and off to keep the tank pressure maintained as the air is consumed.

7.Shut the unit off by pushing the pressure switch knob to the off position. Never shut the unit off by unplugging the cord. This will not activate the pump pressure unloader valve, making restarting difficult.