| Express® Lavatory System |

Installation Instructions - For Service Only | |

|

|

Vernatherm™ Mixing Valve Maintenance and Service

*Repair kit

Maintenance Instructions

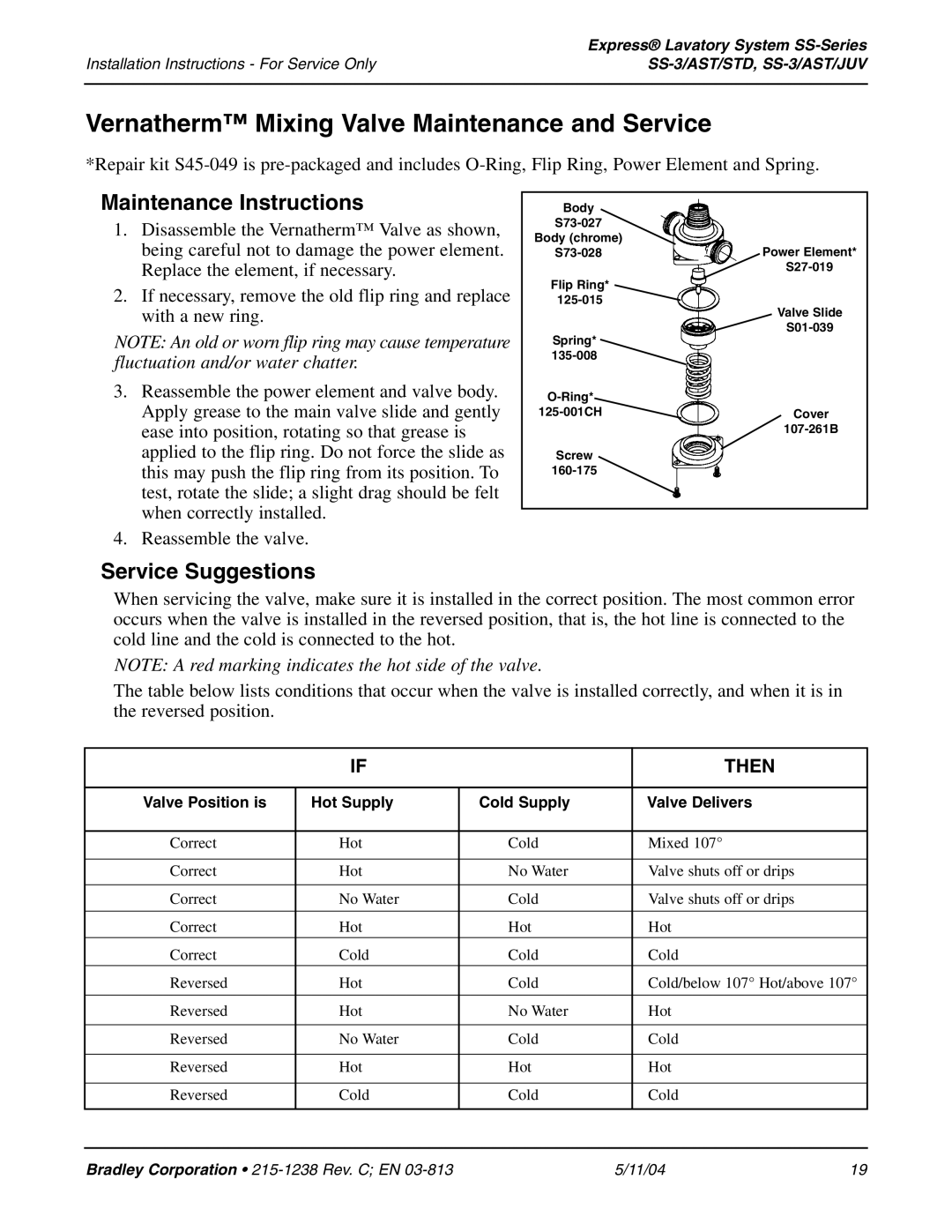

1.Disassemble the Vernatherm™ Valve as shown, being careful not to damage the power element. Replace the element, if necessary.

2.If necessary, remove the old flip ring and replace with a new ring.

NOTE: An old or worn flip ring may cause temperature fluctuation and/or water chatter.

3.Reassemble the power element and valve body. Apply grease to the main valve slide and gently ease into position, rotating so that grease is applied to the flip ring. Do not force the slide as this may push the flip ring from its position. To test, rotate the slide; a slight drag should be felt when correctly installed.

4.Reassemble the valve.

Service Suggestions

Body

Body (chrome)

Flip Ring*

Spring*

Screw

Power Element*

Valve Slide

Cover

When servicing the valve, make sure it is installed in the correct position. The most common error occurs when the valve is installed in the reversed position, that is, the hot line is connected to the cold line and the cold is connected to the hot.

NOTE: A red marking indicates the hot side of the valve.

The table below lists conditions that occur when the valve is installed correctly, and when it is in the reversed position.

| IF |

| THEN |

|

|

|

|

Valve Position is | Hot Supply | Cold Supply | Valve Delivers |

|

|

|

|

Correct | Hot | Cold | Mixed 107° |

|

|

|

|

Correct | Hot | No Water | Valve shuts off or drips |

|

|

|

|

Correct | No Water | Cold | Valve shuts off or drips |

|

|

|

|

Correct | Hot | Hot | Hot |

Correct | Cold | Cold | Cold |

Reversed | Hot | Cold | Cold/below 107° Hot/above 107° |

|

|

|

|

Reversed | Hot | No Water | Hot |

|

|

|

|

Reversed | No Water | Cold | Cold |

|

|

|

|

Reversed | Hot | Hot | Hot |

|

|

|

|

Reversed | Cold | Cold | Cold |

|

|

|

|

Bradley Corporation • | 5/11/04 | 19 |