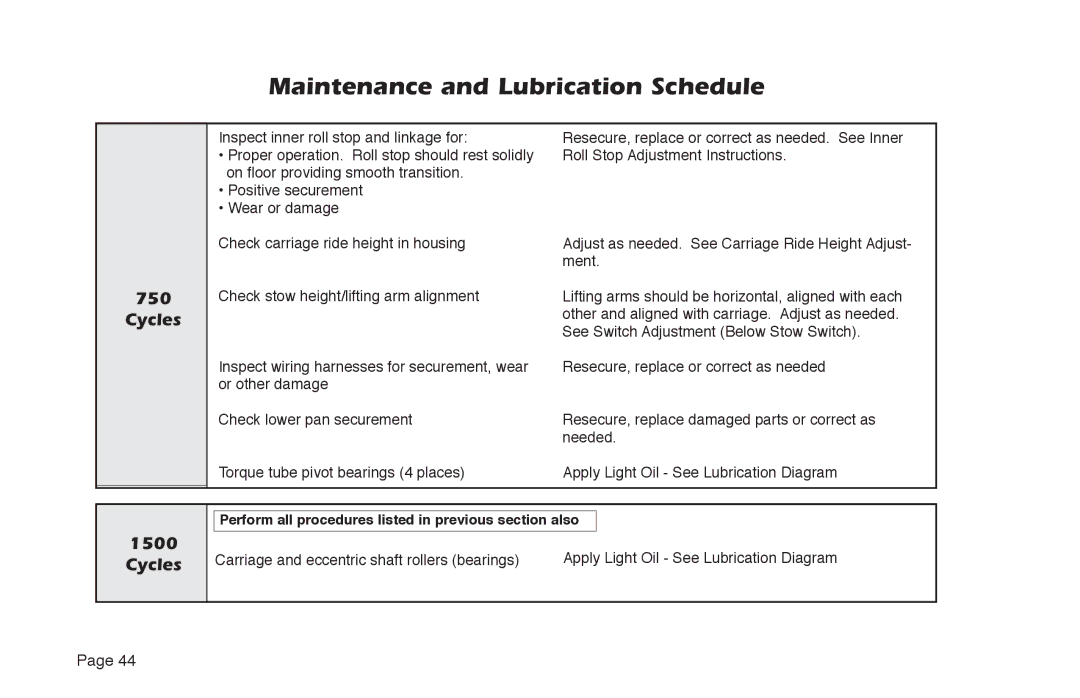

Maintenance and Lubrication Schedule

750

Cycles

Inspect inner roll stop and linkage for:

•Proper operation. Roll stop should rest solidly on floor providing smooth transition.

•Positive securement

•Wear or damage

Check carriage ride height in housing

Check stow height/lifting arm alignment

Inspect wiring harnesses for securement, wear or other damage

Check lower pan securement

Torque tube pivot bearings (4 places)

Resecure, replace or correct as needed. See Inner Roll Stop Adjustment Instructions.

Adjust as needed. See Carriage Ride Height Adjust- ment.

Lifting arms should be horizontal, aligned with each other and aligned with carriage. Adjust as needed. See Switch Adjustment (Below Stow Switch).

Resecure, replace or correct as needed

Resecure, replace damaged parts or correct as needed.

Apply Light Oil - See Lubrication Diagram

1500

Cycles

Perform all procedures listed in previous section also

Carriage and eccentric shaft rollers (bearings) | Apply Light Oil - See Lubrication Diagram |

Page 44