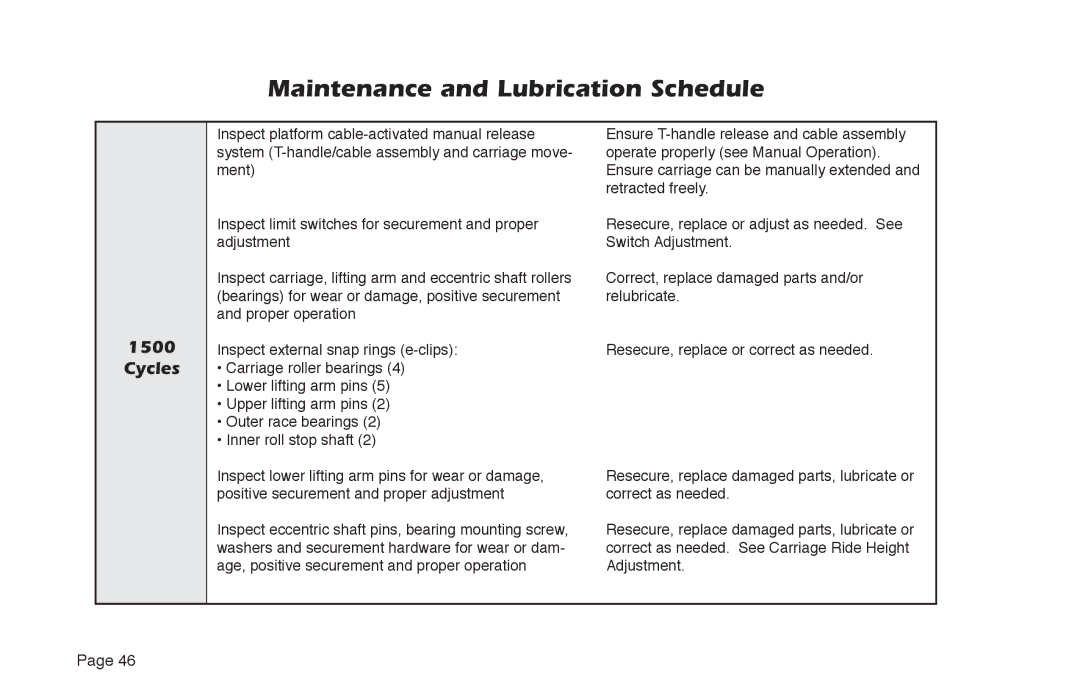

Maintenance and Lubrication Schedule

1500

Cycles

Inspect platform

Inspect limit switches for securement and proper adjustment

Inspect carriage, lifting arm and eccentric shaft rollers (bearings) for wear or damage, positive securement and proper operation

Inspect external snap rings

•Carriage roller bearings (4)

•Lower lifting arm pins (5)

•Upper lifting arm pins (2)

•Outer race bearings (2)

•Inner roll stop shaft (2)

Inspect lower lifting arm pins for wear or damage, positive securement and proper adjustment

Inspect eccentric shaft pins, bearing mounting screw, washers and securement hardware for wear or dam- age, positive securement and proper operation

Ensure

Resecure, replace or adjust as needed. See Switch Adjustment.

Correct, replace damaged parts and/or relubricate.

Resecure, replace or correct as needed.

Resecure, replace damaged parts, lubricate or correct as needed.

Resecure, replace damaged parts, lubricate or correct as needed. See Carriage Ride Height Adjustment.

Page 46