BE-1204B-BC BE-1206B-BC

Page

Safety indications and their meanings

Indications

Damage to equipment and surroundings

Environmental requirements

Installation

Sewing

Cleaning

Maintenance and inspection

Injury caution display

W1206Q

W1207Q W1208Q

Before Starting Operation

Protecting data in floppy disks

Procedure of Reading This Manual

Configuration of this manual

Explanation of models

BE-1204B-BC BE-1206B-BC

Editing of Embroidery data →

Setting of Needle Bars →

Screen Composition

Initial Screen

Setting of Machine →

Setting of thread breakage sensor →

Contents

Setting of Needle Bars Thread Breakage Sensor

Setting

Greasing

Maintenance

Chapter Error code list Troubleshooting

BE-1204B-BC BE-1206B-BC

Chapter Preparation of Embroidery Machine

Specifications

Accessories

Names of Machine Components

Transportation of Machine

Installation

Sewing machine weights more than

When using a fork lift

Hook on the eyebolts with each belt to lift up the machine

When using a crane

Installation of Machine

Preparation of Needle Bar Case

Preparation for mounting the table

Mounting of Table

W1227Q

For embroidering with flat hoop/sash frame upper position

Mounting of Cotton Stand

Lubrication to Needle Bar Case

Grounding

Upper Threading

Preparation for Embroidering

W1234Q

Put a new bobbin in the bobbin case

Replacement of Bobbin

Removing bobbin case

Replacing bobbin

Attaching bobbin case

Attaching needle

Replacing and Selecting Needle

Selecting needle

Removing needle

Tubular square hoop

Attachment of Embroidery Hoop and Frame

Holder base optional

W1246Q

Sash frame optional

Adjustment of Thread Tension

Adjustment of upper thread

Adjustment of tension spring

Lower thread tension

BE-1204B-BC BE-1206B-BC

Chapter Embroidering Procedures

Operation Panel

Functions of Operation Panel

W1254Q

Operation panel

Switches at Machine Heads

Lamps and switches on the thread tension stand

Flowchart of Preparation for Embroidering

Turn on the Machine Power

Retrieve the Embroidery Data

Start Embroidering

Press key

BE-1204B-BC BE-1206B-BC

Chapter Selection of Data and Embroidering

What Can the Machine Do?

Selection of Embroidery Data

Embroidering Operation

These icons are displayed in the lower right of the screen

Selection of Data

Registration of Embroidery Data from Floppy Disk

Other data

Loading and Loading of Floppy Disk

Registration of Sewing Data into Machine Memory

Load a floppy disk with sewing data

Pressing displays a pattern name

Press Select a screen for data registration by pressing

Select data to register by pressing ten keys or then press

Initial screen is displayed

Reading from Memory

Select a screen by pressing

Select embroidery data to read by pressing ten keys or

Press Select the data registration screen by pressing

Registration of Embroidery Data from BES-100E

Select embroidery data to delete by pressing ten keys or

Deletion of Embroidery Data from Machine Memory

Prepare the BES-100E, and then press

Embroidery data can be deleted from the machine memory

Confirm the description to delete, press switch

When is pressed, the confirmation message is displayed

Tape Reader Input Setting

Set device to read from to memory

Press four times

Choose the type of the tape data with keys

Underbar, hyphen Use

Modification of Embroidery Data Name

When modifying embroidery data names entirely

After inputting a data name, press

Press once

Press twice and display N reversely

When modifying only one character

Select a hoop to set on the machine

Sewing Operation

Before Starting Sewing

Starting Sewing Operation

Press while sewing is interrupted

Feedhold and Cancellation of Sewing

Cancellation

Feedhold

Select a required item as described above by pressing

Step Forward/Step-Back Mode

Setting Amount or Timing of Step Forward/Step-Back

Step Forward and Step-Back

Resuming Sewing

For Step Forward Back

Writing the embroidering data

Selected embroidering data is stored on the floppy disk

Chapter Editing of Embroidering Data

Editing

Pattern can be rotated

Rotation

Enlargement and Reduction

Pattern can be enlarged or reduced

Input enlargement/reduction ratio by pressing ten keys

Is reversed in black

Right/Left Mirror Pattern

Mirror

Pattern can be reversed as if it is reflected in the mirror

Sewing data is read Press

Zero Point-Symmetric Mirror Pattern

Up/Down Mirror Pattern

Pattern is repeatedly copied as many times as specified

Repetition

Select the direction of repetitions by pressing

Input intervals between repetitions by pressing ten keys

Other Editing

Stitch Deletion

Thread Trimming Feed Number

Reverse by pressing

Select the number of feeds by pressing

Swing Width Correction

Select a correction amount in the X direction by pressing

BE-1204B-BC BE-1206B-BC

Setting

Setting of Environment

Setting of Needle Bars

Setting of Thread Breakage Sensor

Setting of Machine

Hoop Retract Point

Setting of Lock Stitch

Setting of speed limit in a small pitch

Display of Information

Insertion of Hoop Retract

Setting of Needle Bars

Input the number of a needle bar by pressing ten keys

Insertion of Feedhold

W0485Q

Sensitivity of the thread breakage sensor can be set

Setting of sensor validity/invalidity

Thread Breakage Sensor

Thread Breakage Sensitivity

Automatic Step-Back

Setting of Lower Thread Counter/Stitch Counter

Setting of Machine

Embroidery Hoop

Specify a type of an embroidery hoop set on the machine

Input a required speed range by pressing ten keys

Speed Range

Range of speed for each needle bar can be set

Select a needle bar by pressing

Input a required speed by pressing ten keys

Speed of Each Speed Range

Maximum speed of each range can be set

Select a speed range to modify by pressing

Refer to Mending → Press Select by pressing

Setting of Mending

Contents of each setting item are as described below

Details of mending can be set in case of a thread breakage

Setting of thread breakage error resetting method

Setting of thread trimming method after stopping

Setting of mending stop position

Input thread length by pressing ten keys

After setting is finished with all needle bars, press

Thread Trimming Length

Select a needle bar to modify by pressing

Thread Withdrawal Feed Length

Thread withdrawal length can be set before thread trimming

Input thread withdrawal length by pressing ten keys

Inching

Press Set whether to select the inching mode by pressing

An allowable area for sewing can be set

Sewing Area

Cancellation of Setting

Registration of Sewing Start Position

Register a position to start sewing

Initial screen is displayed again

Hoop Automatic Retract

Movement to Registered Sewing Start Point

This operation should be done before starting sewing

Setting of Environment

Return to Start Point

Press twice Select by pressing

Checking the Embroidery Area

Press Select or by pressing

Press twice Select with

Press Press to select

Press to change the settings

Press or for the selection when using the needle bar No

Slow sewing needle number at start-up

Select communication speed by pressing Press

Setting of RS-232C Communication Speed

Press Input the needle number using ten keys

Select RS Speed by pressing

Select Language by pressing

Display Language

Language to display on the screen can be set

Following languages can be selected

Select Beep by pressing

Alarm Sound

Whether to generate a sound in case of an error can be set

Following sounds can be set

Select Motive Speed with

Motive Speed

Startup speed of the main shaft can be set

Following startup speed can be set

Select the maximum stitch to be deleted with

Stitches less than preset can be deleted

Small-Pitch Deletion

Select Del. small stch with

Select Auto pause ins. by pressing

Automatic pause insertion

Setting lock stitch at the sewing start position

Lock Stitch

Press to validate or invalidate the lock stitch

Setting the lock stitch on the sewing send position

W0566Q

Designate the speed to be limited with

Speed can be limited when stitching in a designated pitch

Speed Limit in a Short Pitch

Designate the stitch length to be limited with

Designate the feed end angle with

Press the button after the setting screen is displayed

Feed Timing

Invalidating speed limit in a short pitch

Automatic Input Setting

Press three times Select with keys

Press to start the sewing

Press when the sewing is completed

Press three times Select by pressing

Contents of information to be displayed are as shown below

Display of Information

Pattern Information

Features of Machine

Detailed information of the machine can be checked

Check information about the machine

Information about Versions

Information about CPU ROM version, etc. can be checked

Check information about versions

BE-1204B-BC BE-1206B-BC

Operation of Machine

Operating Procedures

Power Source

Preparation for Embroidering

Emergency Stop of the Machine

Resetting Emergency Stop

Machine Stop

Stopping the Machine

Remedies

Measures against Thread Breakage

Mending

Case of Mending usage

Manual operation of the mending

Jog Embroidering

Hoop Feed Position

Area Check

External Tracing

Automatic Hoop Movement in Area

Hoop Movement to Start Position

Jog Switches

Pressing resets the inching mode Press restarts embroidering

Inching Mode during Embroidering Forcible Hoop Movement

Hoop moves and the home position is detected

Detection of Home position

Maintenance

Cleaning and Lubrication of Rotary Hook

Cleaning

Cleaning of Needle Plate

Oiling

Head

Supply oil to the following places at regular intervals

Lubricate the lower shaft bush F every 3 months

Lower shaft

Greasing

Cam grooves

Supply grease to the following places at regular intervals

Attach the head cover front L

Grease all the cam grooves of the work clamp cam

Attach the table cover L

Lower gear

Driving shaft

Attach the bed cover B

Attach the head cover R

Needle bar flip-up mechanism

For four head models, just remove the X-feed cover R 2 only

Feed Guide Section

Adjustment

Adjusting Needle Bar Height

BE-1204B-BC BE-1206B-BC

When using the bottom dead center gauge

BE-1204B-BC BE-1206B-BC

Attachment and Adjustment of Rotary Hook

Fully tighten the screw

Adjustment of Presser Foot Height

Adjustment of Thread Trimmer

Attaching the Fixed Knife

Checking the Movable Knife Position

Bad example Toward

W1317Q W1320Q

Thread Wiper Adjustment

Error code list

Error

Error 1A

XY CPU

Error A6

Error BB, BF

Error E5

Error F9

Troubleshooting

Mechanical Section

Once again

Electrical Section

10-5

10-6

10-7

Troubleshooting 10-8

Chapter Connection and Installation Optional Equipment

Attaching Bobbin Winder

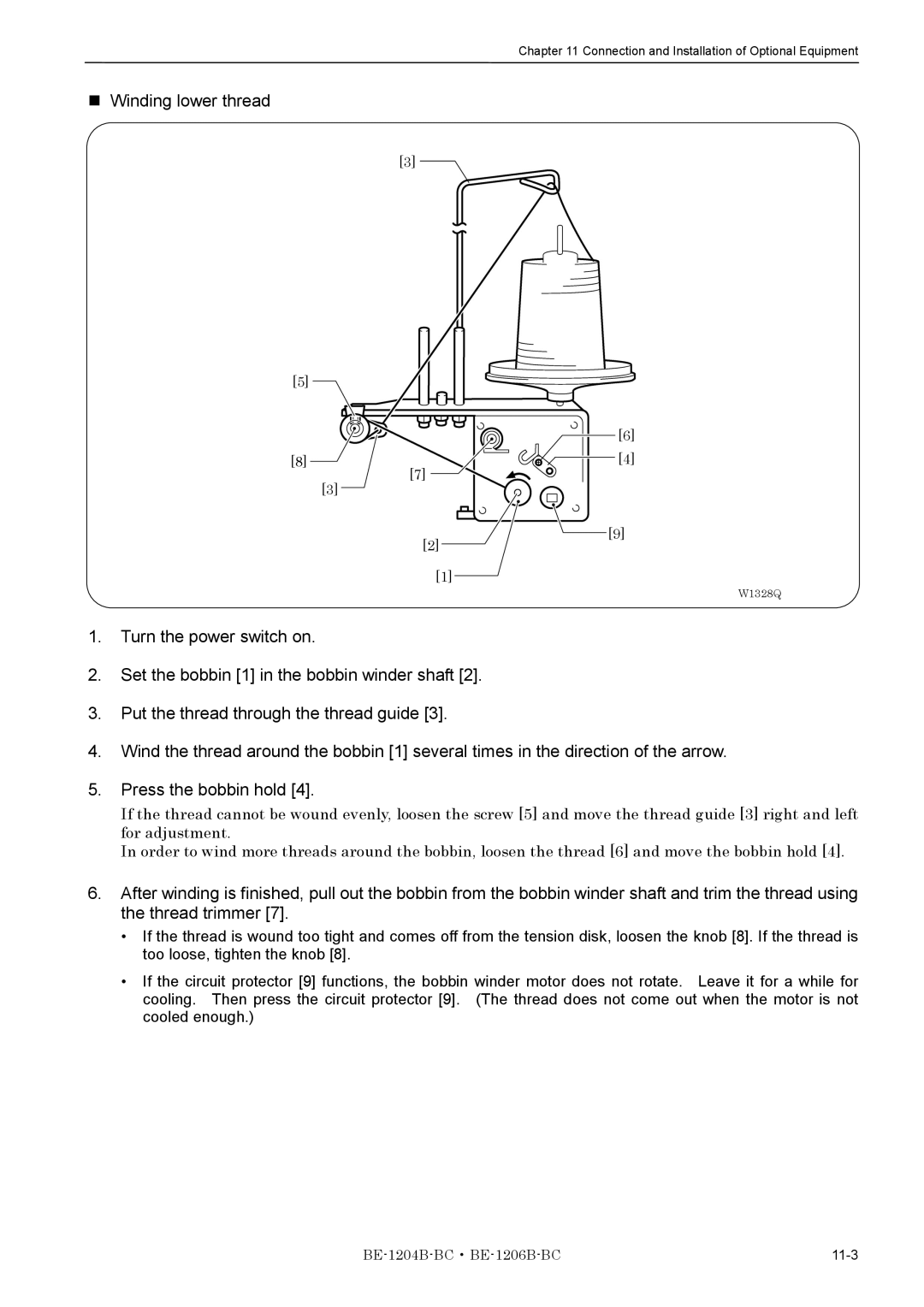

Winding lower thread

Connection and Installation of Optional Equipment 11-4

Page

Naeshiro-cho, Mizuho-ku, Nagoya 467-8561, Japan. Phone