BE-210-WT4T7 specifications

The Bryan Boilers BE-210-WT4T7 is a remarkable product in the steam and hot water boiler market, specifically designed for efficient performance and reliability. This model showcases advanced engineering and technology, setting new standards for commercial and industrial heating solutions.One of the key features of the BE-210-WT4T7 is its water tube design. This construction allows for higher pressure capabilities and provides superior heat transfer. The water tube system enhances the thermal efficiency of the boiler, enabling it to generate steam quickly and maintain consistent output. This efficiency translates to reduced fuel consumption and operating costs, making it an economical choice for businesses.

The BE-210-WT4T7 utilizes the latest advancements in boiler technology, including a flexible combustion design that accommodates various fuel types. This flexibility ensures that users can adapt the boiler to their specific energy needs, whether operating on natural gas, propane, or other fuel types. The ability to switch fuels also contributes to greater operational resilience.

In addition to its fuel flexibility, this boiler features a high-capacity, modular design. This modularity not only simplifies installation but also allows for easy scaling to meet future demand. The design enhances operational efficiency, as smaller units can be added or removed without the need for extensive system overhauls.

Safety and ease of maintenance are also prioritized in the BE-210-WT4T7. It is equipped with advanced safety controls that monitor pressure, temperature, and water flow, ensuring optimal operation and reducing the risk of accidents. Maintenance is straightforward, with accessible components that simplify service tasks and minimize downtime.

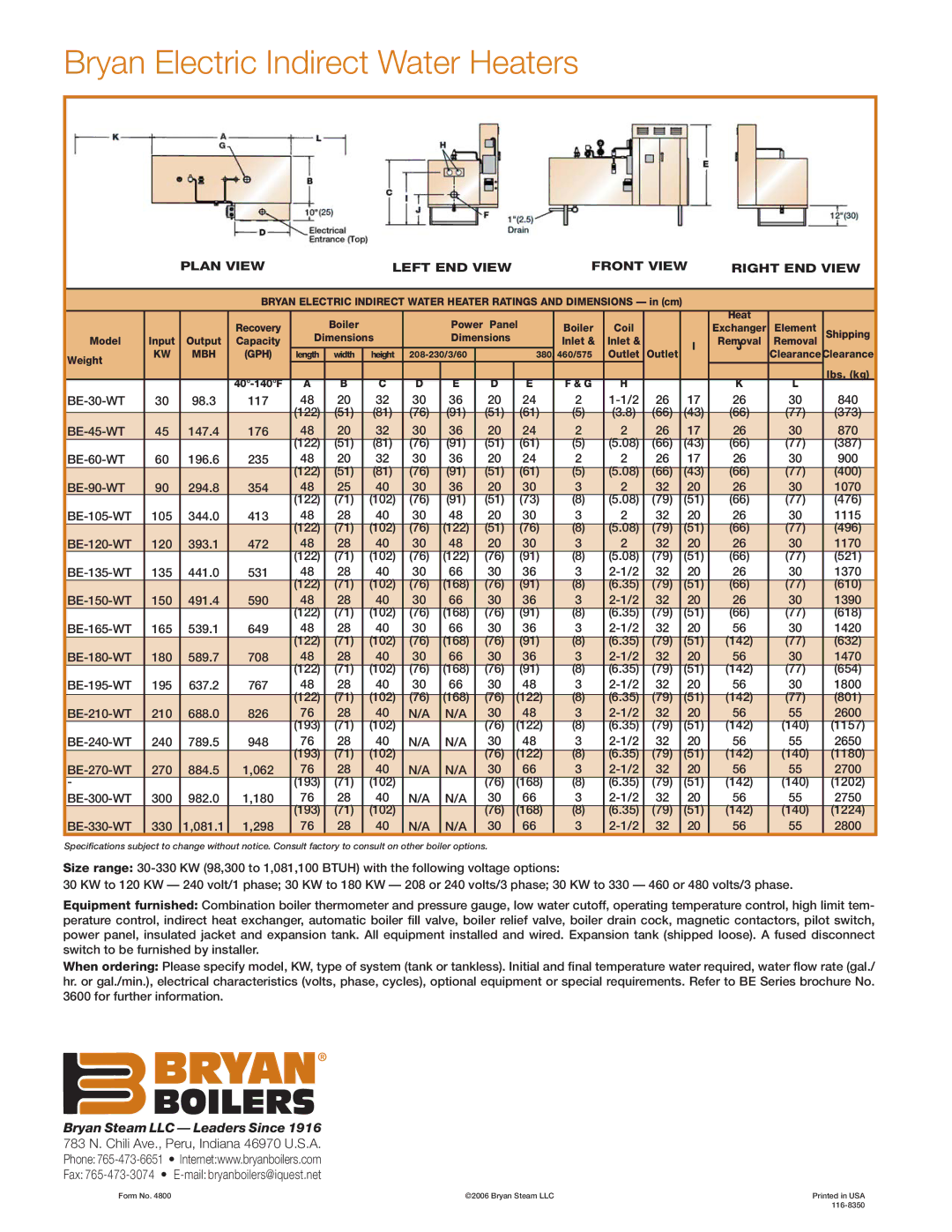

Another notable characteristic of the BE-210-WT4T7 is its compact footprint. This feature enables installation in locations where space is limited without compromising performance. Its robust construction ensures durability and long service life, making it a reliable investment for any facility.

In summary, the Bryan Boilers BE-210-WT4T7 combines innovative technology with practical design features. Its efficient water tube construction, fuel flexibility, modular capability, safety systems, and compact design make it a standout option for those seeking dependable steam or hot water solutions. Whether for industrial or commercial use, the BE-210-WT4T7 is engineered to meet the diverse demands of modern heating applications, ensuring consistent performance and energy efficiency.