286A / 288A

One Minute Stage Change Time Delay on 286A Models

When compressor changes stages from high to low or low to high, there is a

Compressor Operation on 286A Models

When the compressor operates in high stage operation, the compressor motor rotates clockwise. Both the lower and upper pistons are eccentric with the rotating crankshaft and both compress refrigerant.

When the compressor operates in low stage operation, the compressor motor reverses direction (rotates counterclockwise). The lower piston becomes idle and the upper piston compresses refrigerant. The start and run windings are reversed.

Crankcase Heater Operation

The crankcase heater is energized during unit off cycle regardless of outside air temperature (OAT) on 286A models.

The crankcase heater is energized during off cycle below 65°F (18.33°C) on 288A models.

Outdoor Fan Motor Operation

The outdoor unit control energizes outdoor fan anytime compressor is operating, except for defrost or

On 286A models, the outdoor fan motor is a PSC type. A fan relay on the control board turns the fan off and on by opening and closing a high voltage circuit to the motor. It does not change speeds between low and high stage operation.

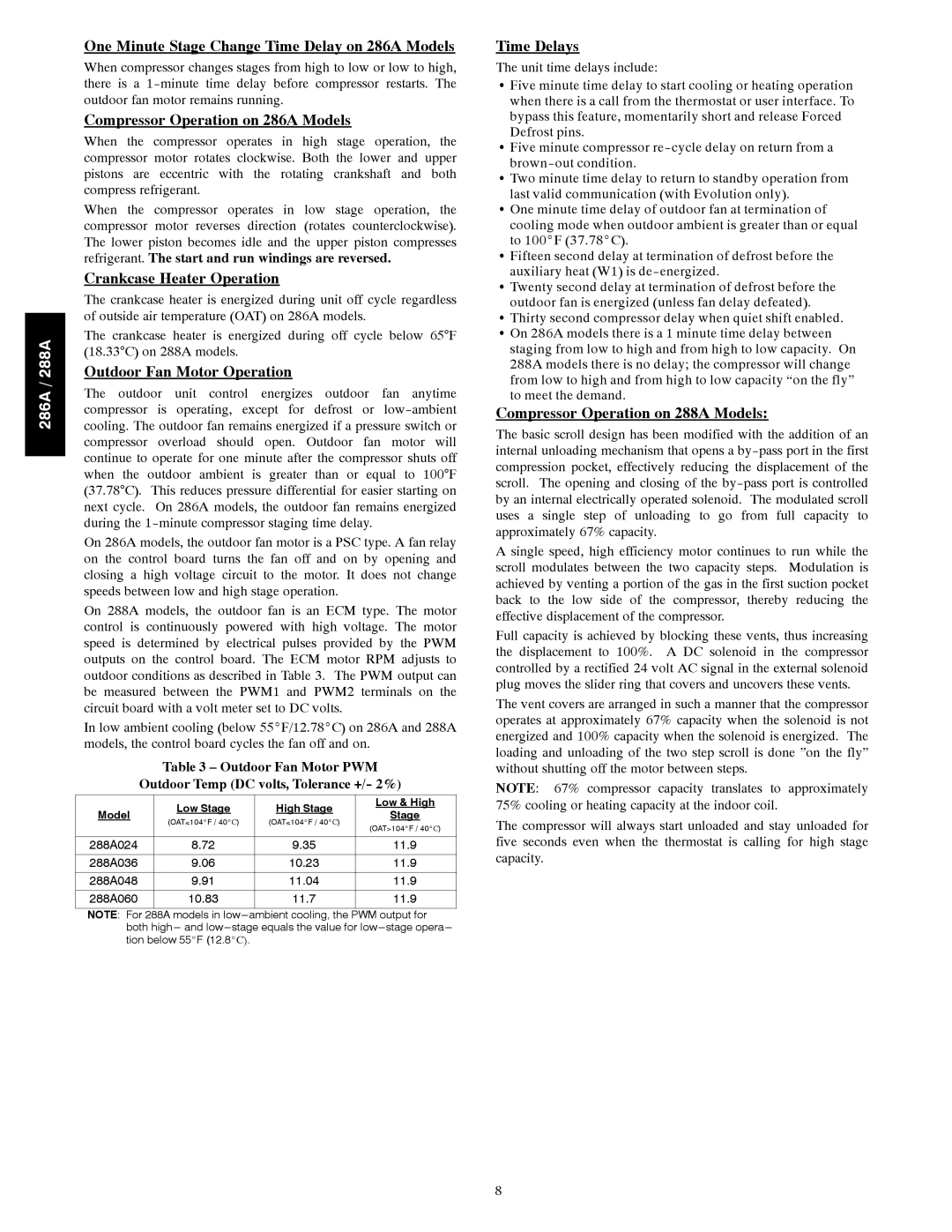

On 288A models, the outdoor fan is an ECM type. The motor control is continuously powered with high voltage. The motor speed is determined by electrical pulses provided by the PWM outputs on the control board. The ECM motor RPM adjusts to outdoor conditions as described in Table 3. The PWM output can be measured between the PWM1 and PWM2 terminals on the circuit board with a volt meter set to DC volts.

In low ambient cooling (below 55_F/12.78_C) on 286A and 288A models, the control board cycles the fan off and on.

Table 3 – Outdoor Fan Motor PWM

Outdoor Temp (DC volts, Tolerance +/- 2%)

| Low Stage | High Stage | Low & High | |

Model | Stage | |||

(OAT≤104_F / 40_C) | (OAT≤104_F / 40_C) | |||

| (OAT>104_F / 40_C) | |||

|

|

| ||

|

|

|

| |

288A024 | 8.72 | 9.35 | 11.9 | |

288A036 | 9.06 | 10.23 | 11.9 | |

|

|

|

| |

288A048 | 9.91 | 11.04 | 11.9 | |

|

|

|

| |

288A060 | 10.83 | 11.7 | 11.9 |

NOTE: For 288A models in

tion below 55_F (12.8_C).

Time Delays

The unit time delays include:

SFive minute time delay to start cooling or heating operation when there is a call from the thermostat or user interface. To bypass this feature, momentarily short and release Forced

Defrost pins.

SFive minute compressor

STwo minute time delay to return to standby operation from

last valid communication (with Evolution only).

SOne minute time delay of outdoor fan at termination of

cooling mode when outdoor ambient is greater than or equal to 100_F (37.78_C).

SFifteen second delay at termination of defrost before the auxiliary heat (W1) is

STwenty second delay at termination of defrost before the outdoor fan is energized (unless fan delay defeated).

SThirty second compressor delay when quiet shift enabled. S On 286A models there is a 1 minute time delay between

staging from low to high and from high to low capacity. On 288A models there is no delay; the compressor will change from low to high and from high to low capacity “on the fly” to meet the demand.

Compressor Operation on 288A Models:

The basic scroll design has been modified with the addition of an internal unloading mechanism that opens a

A single speed, high efficiency motor continues to run while the scroll modulates between the two capacity steps. Modulation is achieved by venting a portion of the gas in the first suction pocket back to the low side of the compressor, thereby reducing the effective displacement of the compressor.

Full capacity is achieved by blocking these vents, thus increasing the displacement to 100%. A DC solenoid in the compressor controlled by a rectified 24 volt AC signal in the external solenoid plug moves the slider ring that covers and uncovers these vents.

The vent covers are arranged in such a manner that the compressor operates at approximately 67% capacity when the solenoid is not energized and 100% capacity when the solenoid is energized. The loading and unloading of the two step scroll is done ”on the fly” without shutting off the motor between steps.

NOTE: 67% compressor capacity translates to approximately 75% cooling or heating capacity at the indoor coil.

The compressor will always start unloaded and stay unloaded for five seconds even when the thermostat is calling for high stage capacity.

8