Only the latest issues of above codes should be used, and are available from either The National Fire Protection Agency, Bat- terymarch Park, Quincy, MA 02269 or The Canadian Standards Association, 178 Rexdale Blvd., Rexdale, Ontario M9W 1R3

Recognize safety information. This is the safety-alert symbol  . When you see this symbol on the furnace and in instructions or manuals, be alert to the potential for personal injury.

. When you see this symbol on the furnace and in instructions or manuals, be alert to the potential for personal injury.

Understand the signal words DANGER, WARNING, and CAU- TION. These words are used with the safety-alert symbol. DAN- GER identifies the most serious hazards which will result in severe personal injury or death. WARNING signifies a hazard which could result in personal injury or death. CAUTION is used to identify unsafe practices which would result in minor personal injury or product and property damage.

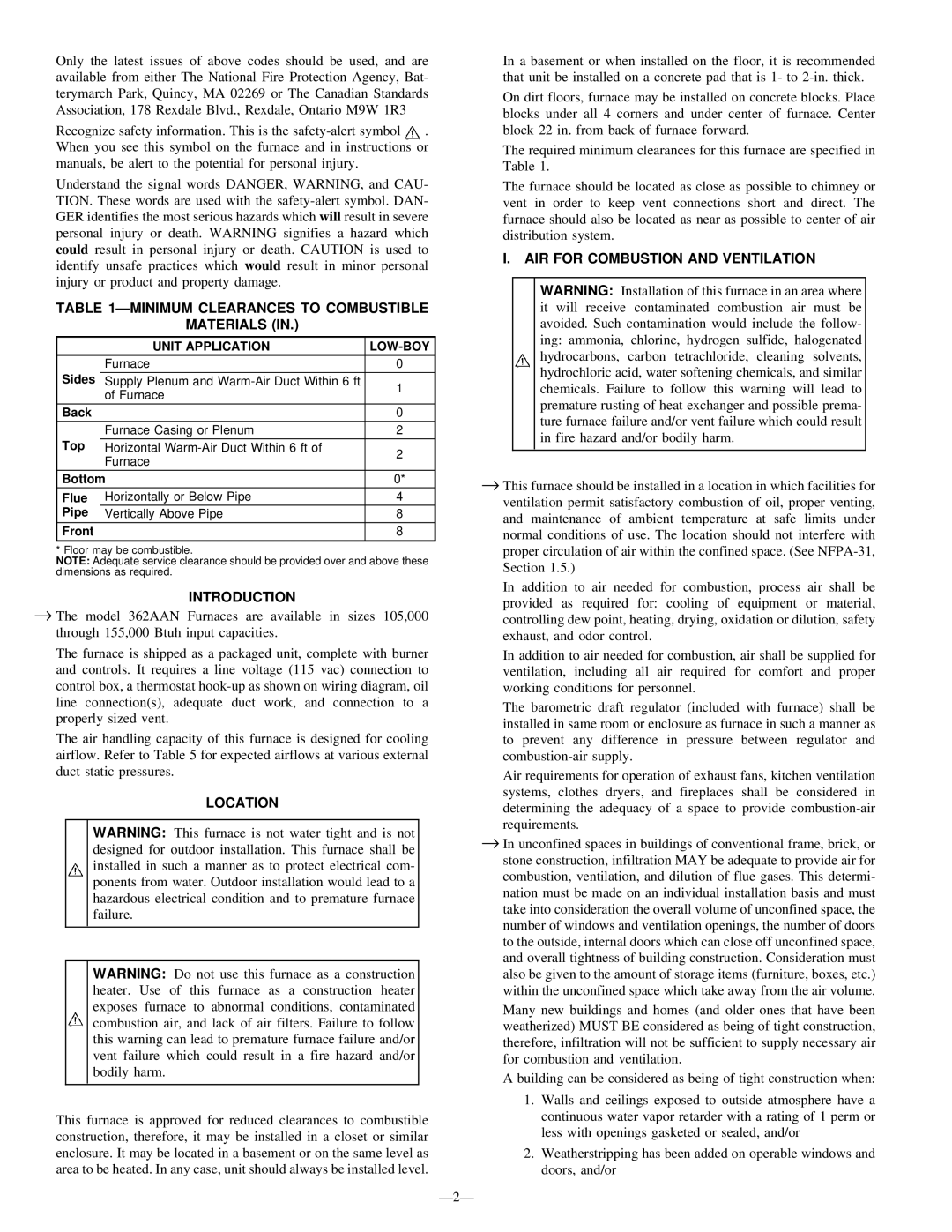

TABLE 1ÐMINIMUM CLEARANCES TO COMBUSTIBLE

MATERIALS (IN.)

| UNIT APPLICATION | LOW-BOY |

| Furnace | 0 |

Sides | Supply Plenum and Warm-Air Duct Within 6 ft | 1 |

| of Furnace |

| |

Back | | 0 |

| Furnace Casing or Plenum | 2 |

Top | | |

Horizontal Warm-Air Duct Within 6 ft of | 2 |

| Furnace |

| |

Bottom | 0* |

Flue | Horizontally or Below Pipe | 4 |

Pipe | Vertically Above Pipe | 8 |

| | |

Front | | 8 |

| | |

* Floor may be combustible.

NOTE: Adequate service clearance should be provided over and above these dimensions as required.

INTRODUCTION

→ The model 362AAN Furnaces are available in sizes 105,000 through 155,000 Btuh input capacities.

The furnace is shipped as a packaged unit, complete with burner and controls. It requires a line voltage (115 vac) connection to control box, a thermostat hook-up as shown on wiring diagram, oil line connection(s), adequate duct work, and connection to a properly sized vent.

The air handling capacity of this furnace is designed for cooling airflow. Refer to Table 5 for expected airflows at various external duct static pressures.

LOCATION

WARNING: This furnace is not water tight and is not designed for outdoor installation. This furnace shall be installed in such a manner as to protect electrical com- ponents from water. Outdoor installation would lead to a hazardous electrical condition and to premature furnace failure.

WARNING: Do not use this furnace as a construction heater. Use of this furnace as a construction heater exposes furnace to abnormal conditions, contaminated combustion air, and lack of air filters. Failure to follow this warning can lead to premature furnace failure and/or vent failure which could result in a fire hazard and/or bodily harm.

This furnace is approved for reduced clearances to combustible construction, therefore, it may be installed in a closet or similar enclosure. It may be located in a basement or on the same level as area to be heated. In any case, unit should always be installed level.

In a basement or when installed on the floor, it is recommended that unit be installed on a concrete pad that is 1- to 2-in. thick.

On dirt floors, furnace may be installed on concrete blocks. Place blocks under all 4 corners and under center of furnace. Center block 22 in. from back of furnace forward.

The required minimum clearances for this furnace are specified in Table 1.

The furnace should be located as close as possible to chimney or vent in order to keep vent connections short and direct. The furnace should also be located as near as possible to center of air distribution system.

I.AIR FOR COMBUSTION AND VENTILATION

WARNING: Installation of this furnace in an area where it will receive contaminated combustion air must be avoided. Such contamination would include the follow- ing: ammonia, chlorine, hydrogen sulfide, halogenated hydrocarbons, carbon tetrachloride, cleaning solvents, hydrochloric acid, water softening chemicals, and similar chemicals. Failure to follow this warning will lead to premature rusting of heat exchanger and possible prema- ture furnace failure and/or vent failure which could result in fire hazard and/or bodily harm.

→This furnace should be installed in a location in which facilities for ventilation permit satisfactory combustion of oil, proper venting, and maintenance of ambient temperature at safe limits under normal conditions of use. The location should not interfere with proper circulation of air within the confined space. (See NFPA-31, Section 1.5.)

In addition to air needed for combustion, process air shall be provided as required for: cooling of equipment or material, controlling dew point, heating, drying, oxidation or dilution, safety exhaust, and odor control.

In addition to air needed for combustion, air shall be supplied for ventilation, including all air required for comfort and proper working conditions for personnel.

The barometric draft regulator (included with furnace) shall be installed in same room or enclosure as furnace in such a manner as to prevent any difference in pressure between regulator and combustion-air supply.

Air requirements for operation of exhaust fans, kitchen ventilation systems, clothes dryers, and fireplaces shall be considered in determining the adequacy of a space to provide combustion-air requirements.

→In unconfined spaces in buildings of conventional frame, brick, or stone construction, infiltration MAY be adequate to provide air for combustion, ventilation, and dilution of flue gases. This determi- nation must be made on an individual installation basis and must take into consideration the overall volume of unconfined space, the number of windows and ventilation openings, the number of doors to the outside, internal doors which can close off unconfined space, and overall tightness of building construction. Consideration must also be given to the amount of storage items (furniture, boxes, etc.) within the unconfined space which take away from the air volume. Many new buildings and homes (and older ones that have been weatherized) MUST BE considered as being of tight construction, therefore, infiltration will not be sufficient to supply necessary air for combustion and ventilation.

A building can be considered as being of tight construction when:

1.Walls and ceilings exposed to outside atmosphere have a continuous water vapor retarder with a rating of 1 perm or less with openings gasketed or sealed, and/or

2.Weatherstripping has been added on operable windows and doors, and/or