OPERATION

OPERATION

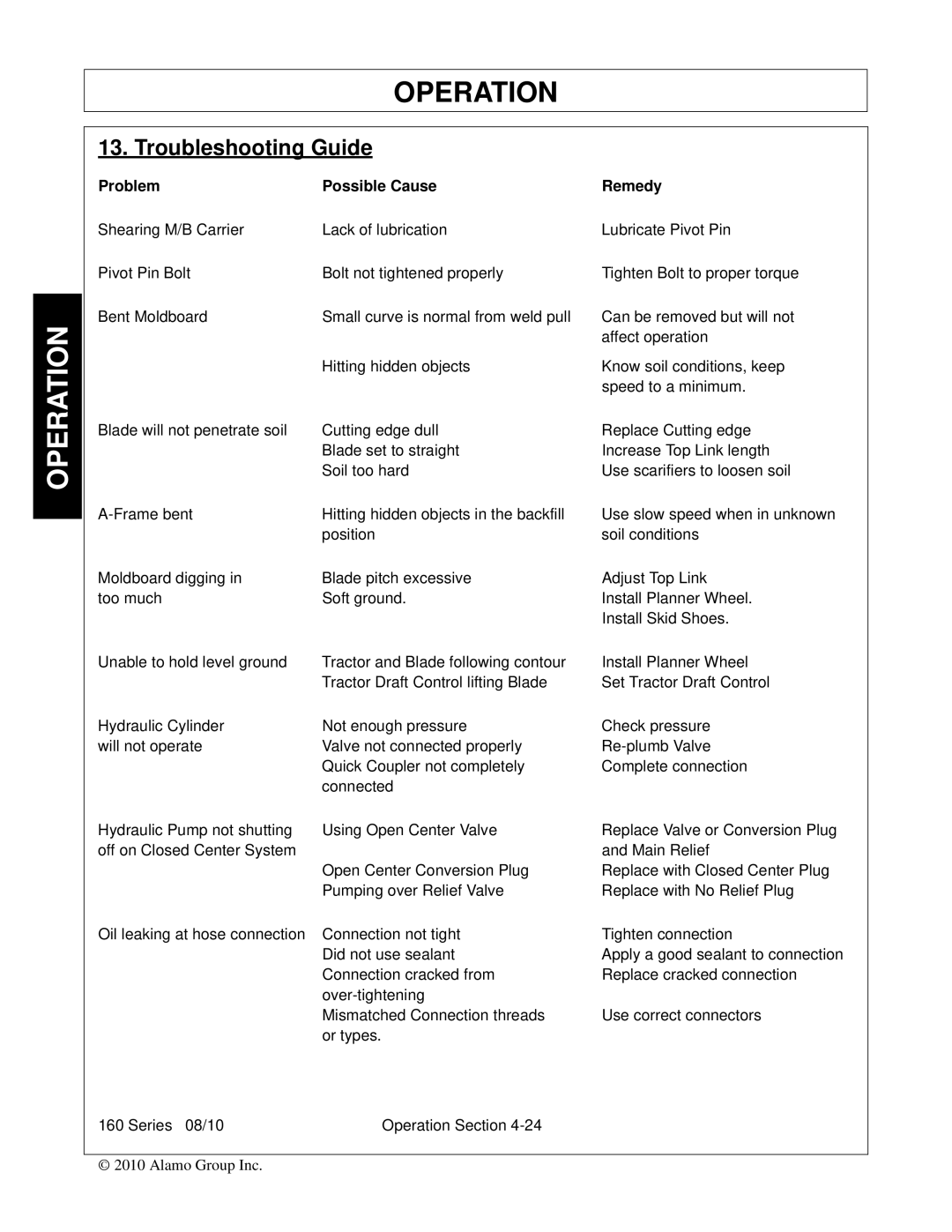

13. Troubleshooting Guide

Problem | Possible Cause |

Shearing M/B Carrier | Lack of lubrication |

Pivot Pin Bolt | Bolt not tightened properly |

Bent Moldboard | Small curve is normal from weld pull |

| Hitting hidden objects |

Blade will not penetrate soil | Cutting edge dull |

| Blade set to straight |

| Soil too hard |

Hitting hidden objects in the backfill | |

| position |

Moldboard digging in | Blade pitch excessive |

too much | Soft ground. |

Unable to hold level ground | Tractor and Blade following contour |

| Tractor Draft Control lifting Blade |

Hydraulic Cylinder | Not enough pressure |

will not operate | Valve not connected properly |

| Quick Coupler not completely |

| connected |

Hydraulic Pump not shutting | Using Open Center Valve |

off on Closed Center System | Open Center Conversion Plug |

| |

| Pumping over Relief Valve |

Oil leaking at hose connection | Connection not tight |

| Did not use sealant |

| Connection cracked from |

| |

| Mismatched Connection threads |

| or types. |

Remedy

Lubricate Pivot Pin

Tighten Bolt to proper torque

Can be removed but will not affect operation

Know soil conditions, keep speed to a minimum.

Replace Cutting edge Increase Top Link length Use scarifiers to loosen soil

Use slow speed when in unknown soil conditions

Adjust Top Link

Install Planner Wheel.

Install Skid Shoes.

Install Planner Wheel

Set Tractor Draft Control

Check pressure

Complete connection

Replace Valve or Conversion Plug and Main Relief

Replace with Closed Center Plug Replace with No Relief Plug

Tighten connection

Apply a good sealant to connection Replace cracked connection

Use correct connectors

160 Series 08/10 | Operation Section |

© 2010 Alamo Group Inc.