SECTION 7: SERVICE

Review the troubleshooting and procedures in this section if a problem develops with your machine. If you need replacement parts or additional help with a procedure, call our Technical Support at (570)

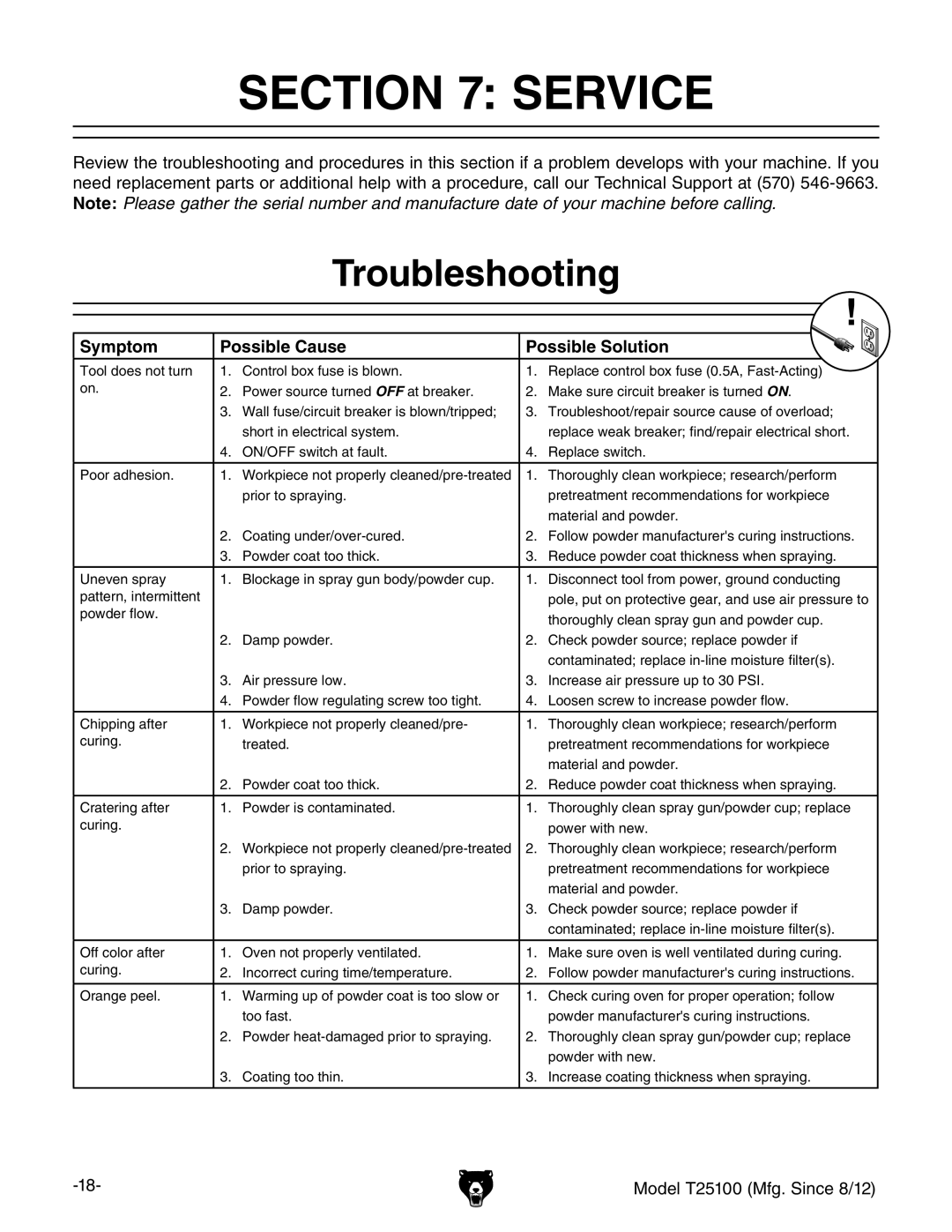

Troubleshooting

Symptom | Possible Cause | Possible Solution | ||

Tool does not turn | 1. | Control box fuse is blown. | 1. | Replace control box fuse (0.5A, |

on. | 2. | Power source turned OFF at breaker. | 2. | Make sure circuit breaker is turned ON. |

| 3. | Wall fuse/circuit breaker is blown/tripped; | 3. | Troubleshoot/repair source cause of overload; |

|

| short in electrical system. |

| replace weak breaker; find/repair electrical short. |

| 4. | ON/OFF switch at fault. | 4. | Replace switch. |

|

|

|

|

|

Poor adhesion. | 1. | Workpiece not properly | 1. | Thoroughly clean workpiece; research/perform |

|

| prior to spraying. |

| pretreatment recommendations for workpiece |

|

|

|

| material and powder. |

| 2. | Coating | 2. | Follow powder manufacturer's curing instructions. |

| 3. | Powder coat too thick. | 3. | Reduce powder coat thickness when spraying. |

|

|

|

|

|

Uneven spray | 1. | Blockage in spray gun body/powder cup. | 1. | Disconnect tool from power, ground conducting |

pattern, intermittent |

|

|

| pole, put on protective gear, and use air pressure to |

powder flow. |

|

|

| thoroughly clean spray gun and powder cup. |

|

|

|

| |

| 2. | Damp powder. | 2. | Check powder source; replace powder if |

|

|

|

| contaminated; replace |

| 3. | Air pressure low. | 3. | Increase air pressure up to 30 PSI. |

| 4. | Powder flow regulating screw too tight. | 4. | Loosen screw to increase powder flow. |

|

|

|

|

|

Chipping after | 1. | Workpiece not properly cleaned/pre- | 1. | Thoroughly clean workpiece; research/perform |

curing. |

| treated. |

| pretreatment recommendations for workpiece |

|

|

|

| material and powder. |

| 2. | Powder coat too thick. | 2. | Reduce powder coat thickness when spraying. |

|

|

|

|

|

Cratering after | 1. | Powder is contaminated. | 1. | Thoroughly clean spray gun/powder cup; replace |

curing. |

|

|

| power with new. |

| 2. | Workpiece not properly | 2. | Thoroughly clean workpiece; research/perform |

|

| prior to spraying. |

| pretreatment recommendations for workpiece |

|

|

|

| material and powder. |

| 3. | Damp powder. | 3. | Check powder source; replace powder if |

|

|

|

| contaminated; replace |

|

|

|

|

|

Off color after | 1. | Oven not properly ventilated. | 1. | Make sure oven is well ventilated during curing. |

curing. | 2. | Incorrect curing time/temperature. | 2. | Follow powder manufacturer's curing instructions. |

|

|

|

|

|

Orange peel. | 1. | Warming up of powder coat is too slow or | 1. | Check curing oven for proper operation; follow |

|

| too fast. |

| powder manufacturer's curing instructions. |

| 2. | Powder | 2. | Thoroughly clean spray gun/powder cup; replace |

|

|

|

| powder with new. |

| 3. | Coating too thin. | 3. | Increase coating thickness when spraying. |

|

|

|

|

|

Model T25100 (Mfg. Since 8/12) |