Site Considerations

Space Allocation

Consider the largest size of workpiece that will be processed with the powder coating system. Provide enough space for adequate operator material handling or the installation of auxiliary equipment.

Physical Environment

The physical environment where this tool is oper- ated is important for safe operation and longevity of the tool components. For best results, operate the powder coating system in a clean, dry environ- ment that is free from excessive moisture, hazard- ous chemicals, airborne abrasives, or extreme conditions. Make sure that all flammable sources (e.g., open flame, hot water heater, welder, etc.) are at least 50 feet away from the work area.

Ventilation

The powder coating and curing processes pro- duce hazardous dust or fumes that can cause

Electrical Installation

Operate this tool near an existing power source. Make sure all power cords are protected from traffic, material handling, moisture, chemicals, or other hazards. Make sure to leave access to a means of disconnecting the power source or engaging a lockout/tagout device, if required.

Lighting

Lighting around the work area must be adequate enough that operations can be performed safely. Shadows, glare, or strobe effect that may distract or impede the operator must be eliminated.

Children and visitors may be seriously injured if unsu- pervised around this tool. Lock entrances to the shop or disable start switch or power connection to prevent unsupervised use.

Moisture Filter

Installation

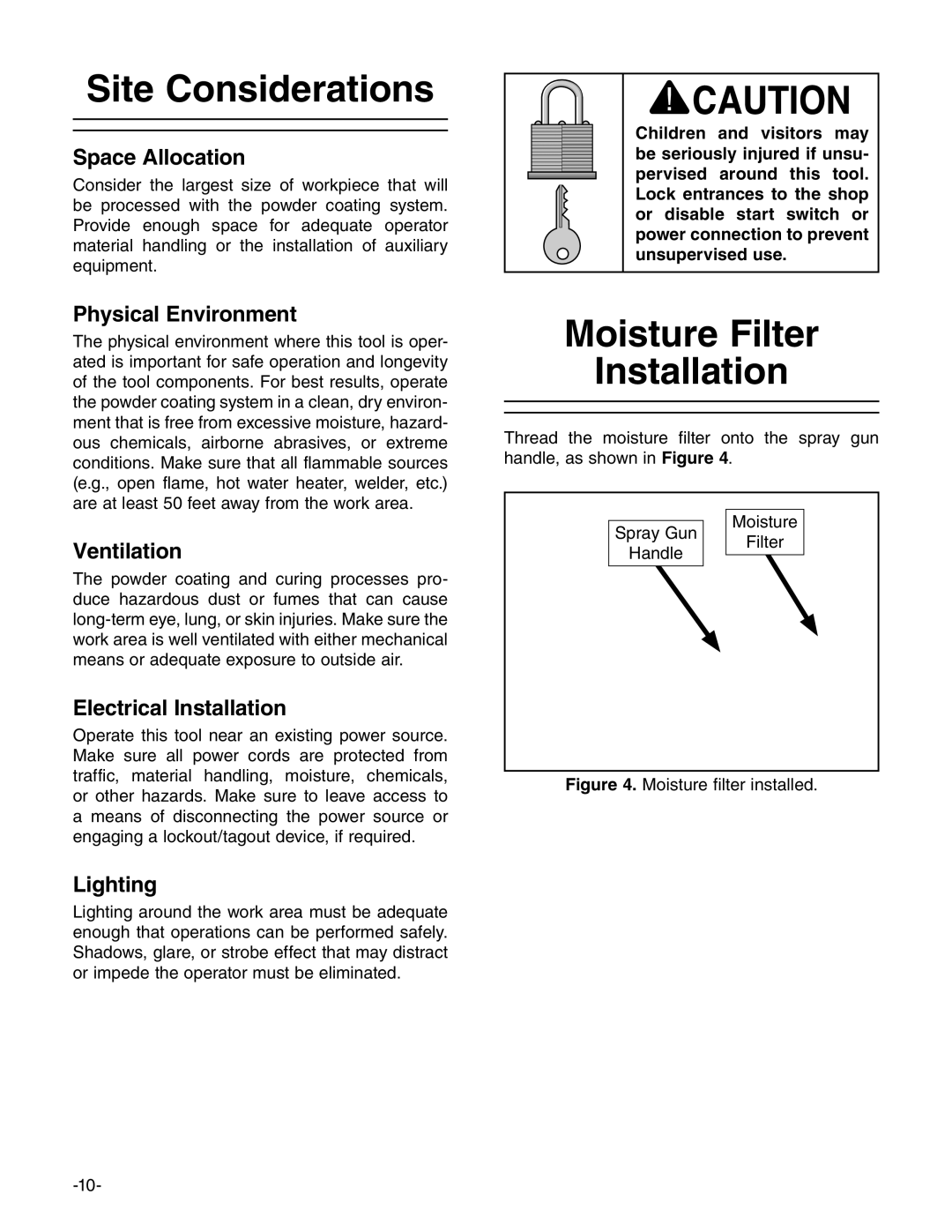

Thread the moisture filter onto the spray gun handle, as shown in Figure 4.

Moisture

Spray Gun Filter

Handle