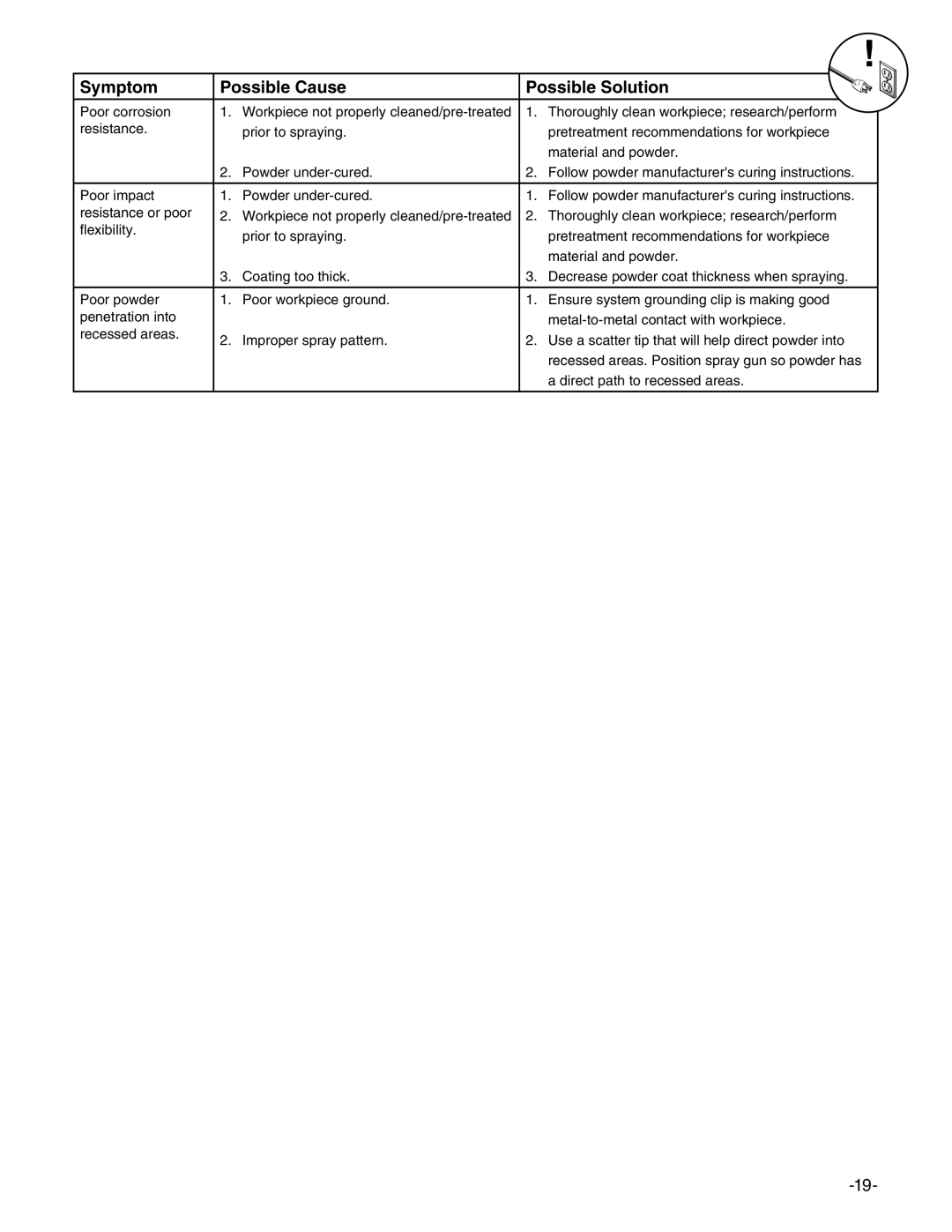

Symptom | Possible Cause | Possible Solution | ||

Poor corrosion | 1. | Workpiece not properly | 1. | Thoroughly clean workpiece; research/perform |

resistance. |

| prior to spraying. |

| pretreatment recommendations for workpiece |

|

|

|

| material and powder. |

| 2. | Powder | 2. | Follow powder manufacturer's curing instructions. |

|

|

|

|

|

Poor impact | 1. | Powder | 1. | Follow powder manufacturer's curing instructions. |

resistance or poor | 2. | Workpiece not properly | 2. | Thoroughly clean workpiece; research/perform |

flexibility. |

| prior to spraying. |

| pretreatment recommendations for workpiece |

|

|

| ||

|

|

|

| material and powder. |

| 3. | Coating too thick. | 3. | Decrease powder coat thickness when spraying. |

|

|

|

|

|

Poor powder | 1. | Poor workpiece ground. | 1. | Ensure system grounding clip is making good |

penetration into |

|

|

| |

recessed areas. | 2. | Improper spray pattern. | 2. | Use a scatter tip that will help direct powder into |

| ||||

|

|

|

| recessed areas. Position spray gun so powder has |

|

|

|

| a direct path to recessed areas. |

|

|

|

|

|

Model T25100 (Mfg. Since 8/12) |