OPERATION

OPERATION

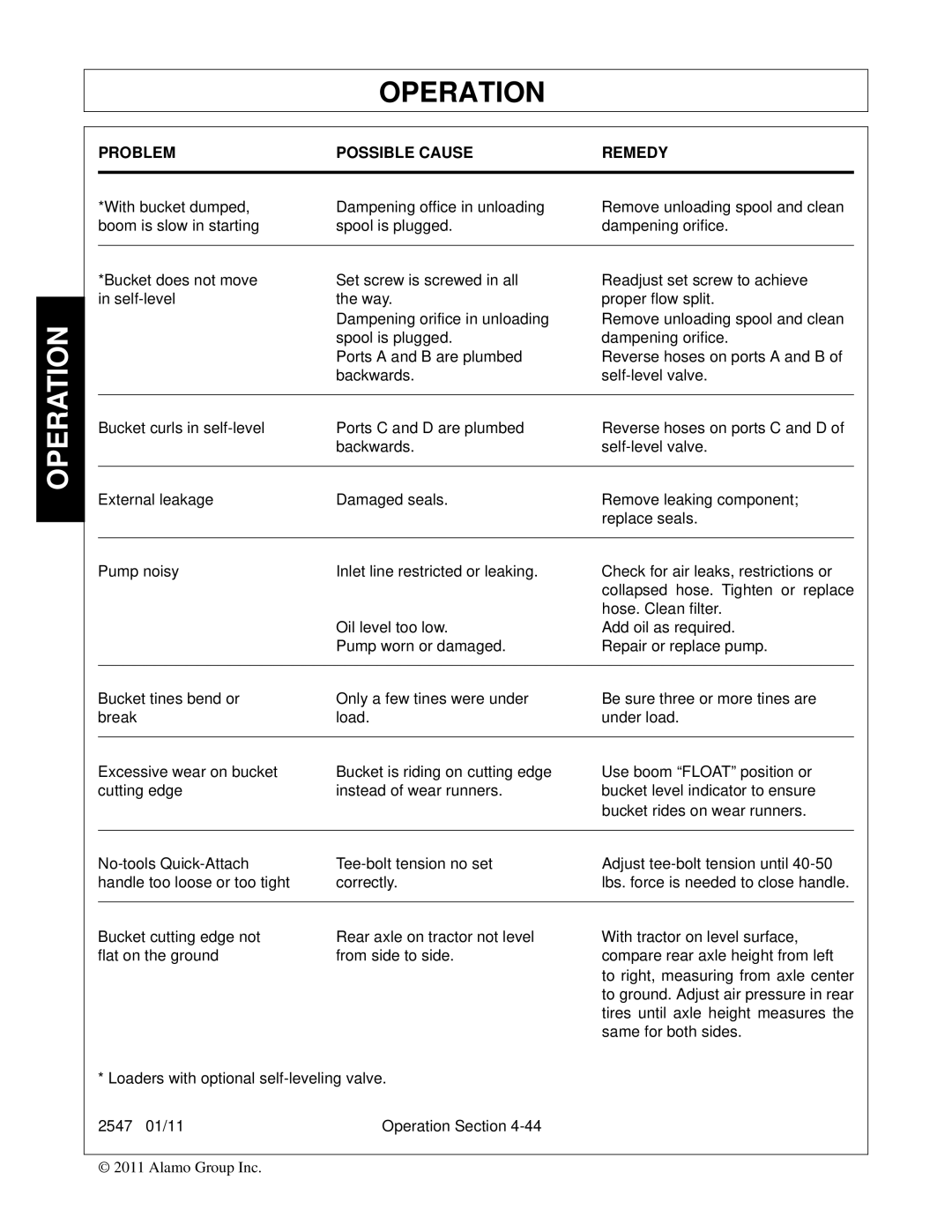

PROBLEM | POSSIBLE CAUSE | REMEDY |

|

|

|

*With bucket dumped, | Dampening office in unloading | Remove unloading spool and clean |

boom is slow in starting | spool is plugged. | dampening orifice. |

|

|

|

*Bucket does not move | Set screw is screwed in all | Readjust set screw to achieve |

in | the way. | proper flow split. |

| Dampening orifice in unloading | Remove unloading spool and clean |

| spool is plugged. | dampening orifice. |

| Ports A and B are plumbed | Reverse hoses on ports A and B of |

| backwards. | |

|

|

|

Bucket curls in | Ports C and D are plumbed | Reverse hoses on ports C and D of |

| backwards. | |

|

|

|

External leakage | Damaged seals. | Remove leaking component; |

|

| replace seals. |

|

|

|

Pump noisy | Inlet line restricted or leaking. | Check for air leaks, restrictions or |

|

| collapsed hose. Tighten or replace |

|

| hose. Clean filter. |

| Oil level too low. | Add oil as required. |

| Pump worn or damaged. | Repair or replace pump. |

|

|

|

Bucket tines bend or | Only a few tines were under | Be sure three or more tines are |

break | load. | under load. |

|

|

|

Excessive wear on bucket | Bucket is riding on cutting edge | Use boom “FLOAT” position or |

cutting edge | instead of wear runners. | bucket level indicator to ensure |

|

| bucket rides on wear runners. |

|

|

|

Adjust | ||

handle too loose or too tight | correctly. | lbs. force is needed to close handle. |

|

|

|

Bucket cutting edge not | Rear axle on tractor not level | With tractor on level surface, |

flat on the ground | from side to side. | compare rear axle height from left |

|

| to right, measuring from axle center |

|

| to ground. Adjust air pressure in rear |

|

| tires until axle height measures the |

|

| same for both sides. |

* Loaders with optional

2547 01/11 | Operation Section |

© 2011 Alamo Group Inc.