ASSEMBLY

FINAL ASSEMBLY CHECKS

1.With the arms at half reach and with the flail head clear of the ground carry out final adjustment of the lift arm levelling box to bring the main frame horizontal.

2.Tighten check chains and/or stabilizer bars.

3.Carefully operate the machine through its full range of movements while checking that hoses are not under tension, pinched, frayed, or kinked and that all movements are functioning correctly.

4.Fold the machine into the transport position. The machine is now ready to proceed to the work site.

OIL REQUIREMENTS

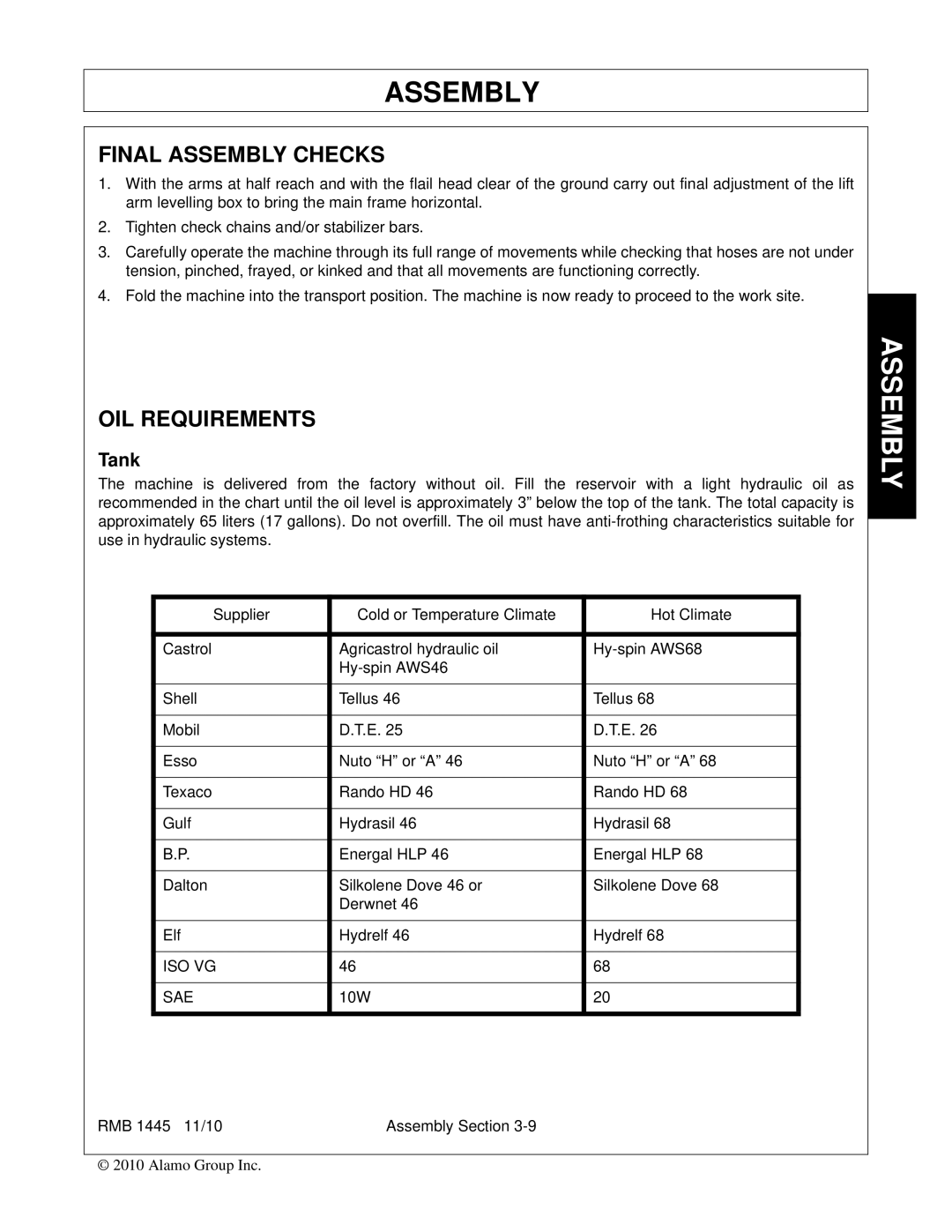

Tank

The machine is delivered from the factory without oil. Fill the reservoir with a light hydraulic oil as recommended in the chart until the oil level is approximately 3” below the top of the tank. The total capacity is approximately 65 liters (17 gallons). Do not overfill. The oil must have

Supplier | Cold or Temperature Climate | Hot Climate |

|

|

|

Castrol | Agricastrol hydraulic oil | |

|

| |

|

|

|

Shell | Tellus 46 | Tellus 68 |

|

|

|

Mobil | D.T.E. 25 | D.T.E. 26 |

|

|

|

Esso | Nuto “H” or “A” 46 | Nuto “H” or “A” 68 |

|

|

|

Texaco | Rando HD 46 | Rando HD 68 |

|

|

|

Gulf | Hydrasil 46 | Hydrasil 68 |

|

|

|

B.P. | Energal HLP 46 | Energal HLP 68 |

|

|

|

Dalton | Silkolene Dove 46 or | Silkolene Dove 68 |

| Derwnet 46 |

|

|

|

|

Elf | Hydrelf 46 | Hydrelf 68 |

|

|

|

ISO VG | 46 | 68 |

|

|

|

SAE | 10W | 20 |

|

|

|

RMB 1445 11/10 | Assembly Section |

© 2010 Alamo Group Inc.