Oil Lubricated Compressors | HL5402 |

Limited Warranty

1. DURATION: From the date of purchase by the original purchaser: One Year. |

2. WHO GIVES THIS WARRANTY (WARRANTOR): |

Campbell Hausfeld / Scott Fetzer Company, 100 Production Drive, Harrison, Ohio, 45030, Telephone: (800) |

3. WHO RECEIVES THIS WARRANTY (PURCHASER): The original purchaser (other than for purposes of resale) of the Campbell Hausfeld |

compressor. |

4. WHAT PRODUCTS ARE COVERED BY THIS WARRANTY: Any Campbell Hausfeld air compressor. |

5. WHAT IS COVERED UNDER THIS WARRANTY: Parts and Labor to remedy substantial defects due to material and workmanship during the |

first year of ownership with the exceptions noted below. |

6. WHAT IS NOT COVERED UNDER THIS WARRANTY: |

A. Implied warranties, including those of merchantability and FITNESS FOR A PARTICULAR PURPOSE ARE LIMITED FROM THE DATE OF |

ORIGINAL PURCHASE AS STATED IN THE DURATION. If the compressor is used for commercial, industrial or rental purposes, the |

warranty will apply for ninety (90) days from the date of purchase. Some States do not allow limitations on how long an implied |

warranty lasts, so the above limitations may not apply to you |

B. ANY INCIDENTAL, INDIRECT, OR CONSEQUENTIAL LOSS, DAMAGE, OR EXPENSE THAT MAY RESULT FROM ANY DEFECT, FAILURE, |

OR MALFUNCTION OF THE CAMPBELL HAUSFELD PRODUCT. Some States do not allow the exclusion or limitations of incidental or |

consequential damages, so the above limitation or exclusion may not apply to you. |

C. Any failure that results from an accident, purchaser’s abuse, neglect or failure to operate products in accordance with instructions |

provided in the owner’s manual(s) supplied with compressor. |

D. |

E. Items or service that is normally required to maintain the product, i.e. lubricants, filters and gaskets, etc. |

F. Gasoline engines and components are expressly excluded from coverage under this limited warranty. The Purchaser must comply with |

the warranty given by the engine manufacturer which is supplied with the product |

G. Additional items not covered under this warranty: |

1. Excluded items pertaining to All Compressors |

a. Any component damaged in shipment or any failure caused by installing or operating unit under conditions not in accordance |

with installation and operation guidelines or damaged by contact with tools or surroundings. |

b. Pump or valve failure caused by rain, excessive humidity, corrosive environments or other contaminants. |

c. Cosmetic defects that do not interfere with compressor functionality. |

d. Rusted tanks, including but not limited to rust due to improper drainage or corrosive environments. |

e. The following components are considered normal wear items and are not covered after the first year of ownership. |

|

|

| HL5402 | |

Instalación |

| máxima vida útil, drene y cambie el | desconectar el cordón eléctrico del | |

| aceite después de la primera hora de | tomacorrientes o para cambiar la | ||

(Continuacíon) |

| |||

| funcionamiento. | herramienta neumática. | ||

producto tiene un cordón con un | La bomba del compresor necesita | • Regulador - El regulador controla la | ||

aproximadamente 175 mL (6 oz) de | ||||

alambre y terminal de conexión a | cantidad de presión de aire | |||

aceite. El visor de vidrio, ubicado en la | ||||

tierra. Debe conectarlo a un | expulsada por la manguera. | |||

caja del cigüeñal de la bomba, sirve | ||||

tomacorrientes que esté instalado | • Válvula de seguridad ASME - Esta | |||

para determinar el nivel apropiado de | ||||

adecuadamente según los códigos y | ||||

aceite. Llene la caja del cigüeñal con | válvula se encuentra en la parte | |||

ordenanzas locales. |

| |||

| aceite hasta que el nivel quede en la | inferior del interruptor de presión. | ||

|

| mitad del visor de vidrio. Evite llenar | Automáticamente liberará el aire si | |

Terminal |

| en exceso, agregando aceite en forma | la presión del tanque excede el valor | |

| gradual y verificando el nivel de aceite | |||

de |

| máximo fijado de fábrica. | ||

| varias veces por medio del visor de | |||

conexión |

| • Tubería de descarga - Esta tubería | ||

a tierra | TEST RESET | vidrio. Agregue suficiente aceite para | ||

|

| que llegue al nivel marcado con “max” | transporta el aire comprimido del | |

|

| en el visor de vidrio. El nivel adecuado | cabezal a la válvula de chequeo. Esta | |

Tomacorrientes conectado a tierra | de aceite está ilustrado en la Figura 3. | tubería se calienta excesivamente | ||

| durante el uso. Para evitar | |||

Figura 1 - Método de conexión a |

| |||

| quemaduras graves, nunca la toque. | |||

tierra |

|

| ||

|

| • Válvula de chequeo | ||

|

|

| ||

| Si no | Máx. | está ubicada en el extremo de la | |

| conecta | tubería de descarga donde se | ||

los cables adecuadamente podría haber | Min. | encuentra con el tanque. Esta es una | ||

cortocircuitos, incendios, sobreca- |

| válvula de una vía que el aire entre | ||

lentamiento, etc. |

| Figura 3 – Nivel adecuado de aceite | al tanque y evita que éste se regrese | |

LUBRICACION |

| al cabezal. | ||

|

| |||

| Electric motor, check valve, pressure switch, regulator, pressure gauges, hose, tubing, pipe, fittings and couplers, screws, nuts, |

| hardware items, belts, pulleys, flywheel, air filter and housing, gaskets, seals, oil leaks, air leaks, oil consumption or usage, |

| piston rings. |

f. | Tank drain valves. |

g. | Damage due to incorrect voltage or improper wiring. |

h. | Other items not listed but considered general wear parts. |

i. | Pressure switches, air governors, load/unload devices, throttle control devices and safety valves modified from factory settings. |

j. | Damage from inadequate filter maintenance. |

k. Induction motors operated with electricity produced by a generator. | |

2. Excluded items specific to Lubricated Compressors: | |

a. Pump wear or valve damage caused by using oil not specified. | |

b. Pump wear or damage caused by any oil contamination. | |

c. | Pump wear or damage caused by failure to follow proper oil maintenance guidelines, operation below proper oil level |

| or operation without oil. |

¡ÉSTA

UNIDAD

VIENE DE FABRICA SIN ACEITE! Siga las instrucciones de lubricación antes de utilizar el compresor.

Use el aceite que se envía con el compresor. No utilice aceite automotriz común como por ejemplo

Funcionamiento

•Presostato - Automático - En la posición AUTO el compresor se apaga automáticamente cuando la presión del tanque alcanza el nivel máximo fijado en la fábrica. En la posición OFF, el compresor no funcionará. El presostato debe colocarse en OFF para conectar o

•Mango - Diseñado para mover el compresor.

Nunca use el

mango de las unidades con ruedas para levantar completamente la unidad.

•Llave de drenaje - Esta válvula está ubicada debajo del tanque. Úsela para drenar la humedad del tanque

7. | RESPONSIBILITIES OF WARRANTOR UNDER THIS WARRANTY: Repair or replace, at Warrantor’s option, compressor or component which |

| is defective, has malfunctioned and/or failed to conform within duration of the warranty period. |

8. | RESPONSIBILITIES OF PURCHASER UNDER THIS WARRANTY: |

| A. Provide dated proof of purchase and maintenance records. |

| B. Portable compressors or components must be delivered or shipped to the nearest Campbell Hausfeld Authorized Service Center. |

| Freight costs, if any, must be borne by the purchaser. |

| C. Use reasonable care in the operation and maintenance of the products as described in the owner’s manual(s). |

| D. Repairs requiring overtime, weekend rates, or anything beyond the standard manufacturer warranty repair labor reimbursement |

| rate. |

| E. Time required for any security checks, safety training, or similar for service personnel to gain access to facility. |

| F. Location of unit must have adequate clearance for service personnel to perform repairs and easily accessible. |

9. | WHEN WARRANTOR WILL PERFORM REPAIR OR REPLACEMENT UNDER THIS WARRANTY: Repair or replacement will be scheduled and |

| serviced according to the normal work flow at the servicing location, and depending on the availability of replacement parts. |

This Limited Warranty applies in the U.S., Canada and Mexico only and gives you specific legal rights. You may also have other rights which vary from State to State or country to country.

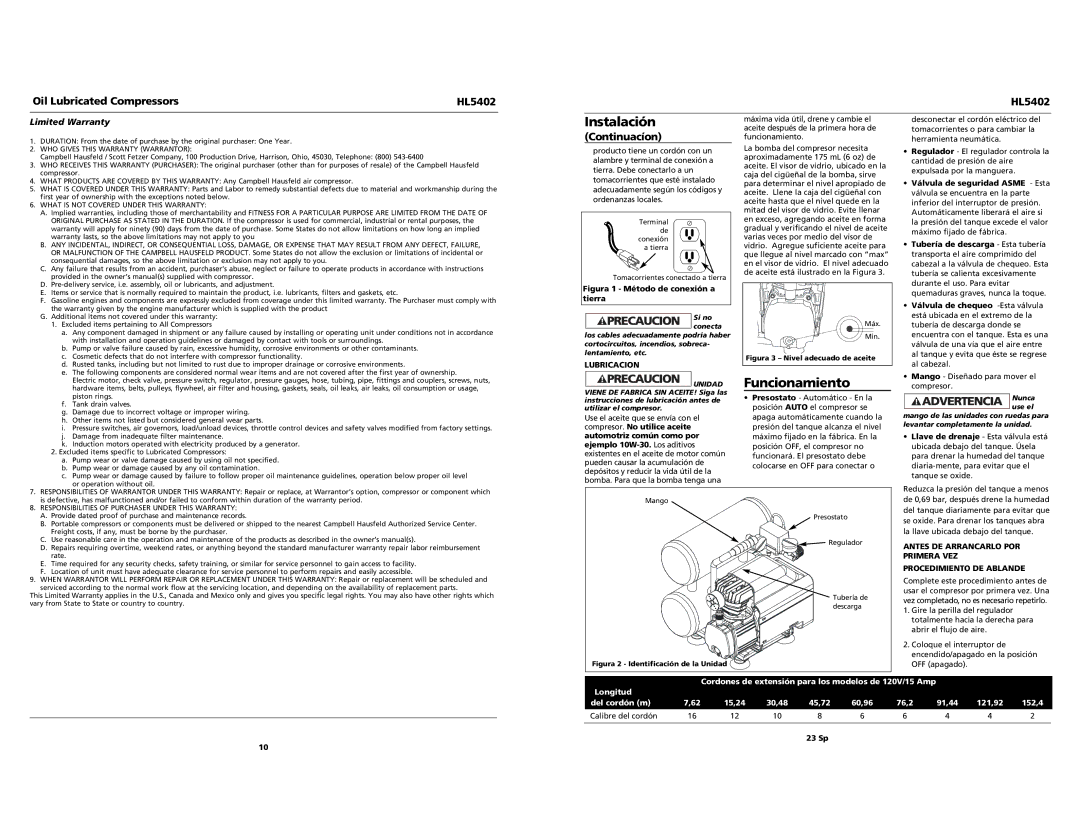

Mango |

Presostato |

Regulador |

Tubería de |

descarga |

Figura 2 - Identificación de la Unidad |

Reduzca la presión del tanque a menos de 0,69 bar, después drene la humedad del tanque diariamente para evitar que se oxide. Para drenar los tanques abra la llave ubicada debajo del tanque.

ANTES DE ARRANCARLO POR PRIMERA VEZ

PROCEDIMIENTO DE ABLANDE

Complete este procedimiento antes de usar el compresor por primera vez. Una vez completado, no es necesario repetirlo.

1.Gire la perilla del regulador totalmente hacia la derecha para abrir el flujo de aire.

2.Coloque el interruptor de encendido/apagado en la posición OFF (apagado).

|

| Cordones de extensión para los modelos de 120V/15 Amp |

|

|

| ||||

Longitud |

|

|

|

|

|

|

|

|

|

del cordón (m) | 7,62 | 15,24 | 30,48 | 45,72 | 60,96 | 76,2 | 91,44 | 121,92 | 152,4 |

Calibre del cordón | 16 | 12 | 10 | 8 | 6 | 6 | 4 | 4 | 2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

| 23 Sp |

|

|

|

|

|

10