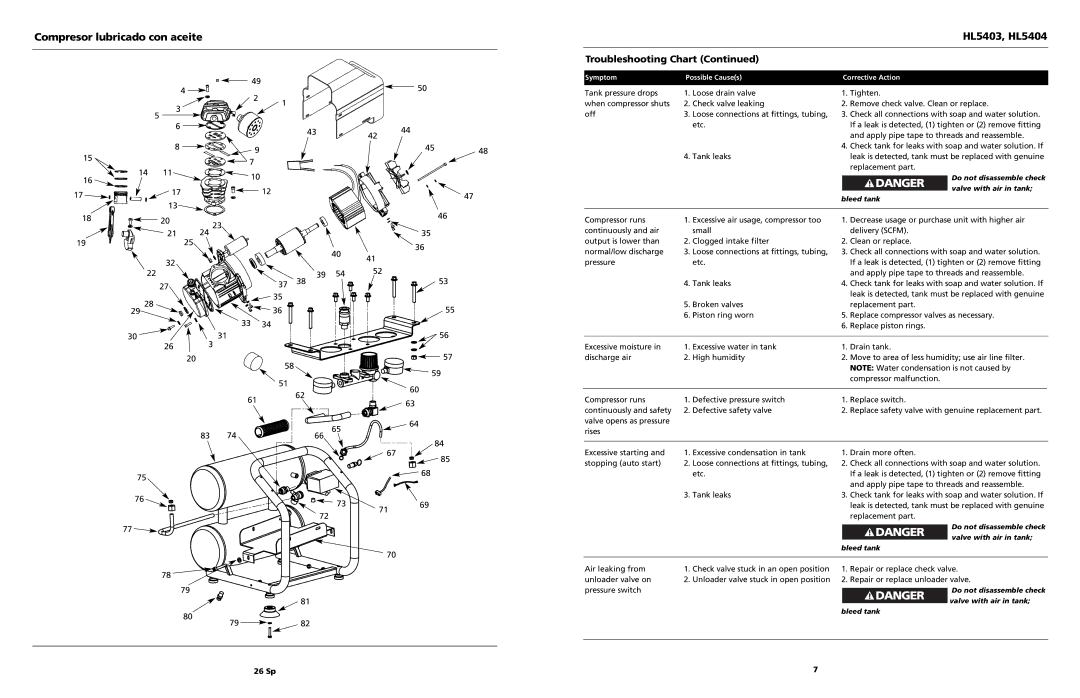

Compresor lubricado con aceite

|

| HL5403, HL5404 |

|

| |

Troubleshooting Chart (Continued) |

| |

Symptom | Possible Cause(s) | Corrective Action |

15

16![]()

17 ![]()

18

19

4

3

| 5 |

|

|

|

|

|

|

| |

| 6 |

|

| |

14 | 8 |

|

| |

|

| |||

11 |

|

| ||

![]() 17 13

17 13

20

![]() 21

21

25

32

49

2

![]() 1

1

43

![]() 9 7

9 7

![]() 10

10

12

23

24

40

42

41

50

44

4548

47

46

35

36

Tank pressure drops | 1. | Loose drain valve | 1. | Tighten. | ||

when compressor shuts | 2. | Check valve leaking | 2. | Remove check valve. Clean or replace. | ||

off | 3. | Loose connections at fittings, tubing, | 3. | Check all connections with soap and water solution. | ||

|

| etc. |

|

| If a leak is detected, (1) tighten or (2) remove fitting | |

|

|

|

|

| and apply pipe tape to threads and reassemble. | |

|

|

| 4. | Check tank for leaks with soap and water solution. If | ||

| 4. | Tank leaks |

|

| leak is detected, tank must be replaced with genuine | |

|

|

|

|

| replacement part. | |

|

|

|

|

|

| Do not disassemble check |

|

|

|

|

|

| |

|

|

|

|

|

| valve with air in tank; |

|

|

|

|

|

| |

|

|

| bleed tank | |||

|

|

|

|

|

|

|

Compressor runs | 1. | Excessive air usage, compressor too | 1. | Decrease usage or purchase unit with higher air | ||

continuously and air |

| small |

|

| delivery (SCFM). | |

output is lower than | 2. | Clogged intake filter | 2. | Clean or replace. | ||

normal/low discharge | 3. | Loose connections at fittings, tubing, | 3. | Check all connections with soap and water solution. | ||

pressure |

| etc. |

|

| If a leak is detected, (1) tighten or (2) remove fitting | |

22

27

28

29

30

26

20

39 54

37 38

![]() 35

35 ![]() 36

36

33 34

31

3

58

51

61 62

65

83 | 74 | 66 |

52

53

55

![]() 56

56

57

59

60

![]() 63

63

![]() 64

64

|

|

|

|

| and apply pipe tape to threads and reassemble. | |

|

| 4. | Tank leaks | 4. | Check tank for leaks with soap and water solution. If | |

|

|

|

|

| leak is detected, tank must be replaced with genuine | |

|

| 5. | Broken valves |

| replacement part. | |

|

| 6. | Piston ring worn | 5. | Replace compressor valves as necessary. | |

|

|

|

| 6. | Replace piston rings. | |

|

|

|

|

|

|

|

| Excessive moisture in | 1. | Excessive water in tank | 1. | Drain tank. | |

| discharge air | 2. | High humidity | 2. | Move to area of less humidity; use air line filter. | |

|

|

|

|

| NOTE: Water condensation is not caused by | |

|

|

|

|

| compressor malfunction. | |

|

|

|

|

|

|

|

| Compressor runs | 1. | Defective pressure switch | 1. | Replace switch. | |

| continuously and safety | 2. | Defective safety valve | 2. | Replace safety valve with genuine replacement part. | |

| valve opens as pressure |

|

|

|

|

|

| rises |

|

|

|

|

|

67

84

![]()

![]() 85

85

Excessive starting and | 1. | Excessive condensation in tank | 1. | Drain more often. |

stopping (auto start) | 2. | Loose connections at fittings, tubing, | 2. | Check all connections with soap and water solution. |

75

![]() 68

68

etc. | If a leak is detected, (1) tighten or (2) remove fitting |

| and apply pipe tape to threads and reassemble. |

3. Tank leaks | 3. Check tank for leaks with soap and water solution. If |

76 | 73 |

| |

| 72 |

77 |

|

78

79

81

80

79 | 82 |

71 | 69 |

|

70

|

|

| leak is detected, tank must be replaced with genuine | |

|

|

| replacement part. | |

|

|

|

| Do not disassemble check |

|

|

|

| |

|

|

|

| valve with air in tank; |

|

|

|

| |

|

| bleed tank | ||

|

|

| ||

Air leaking from | 1. Check valve stuck in an open position | 1. Repair or replace check valve. | ||

unloader valve on | 2. Unloader valve stuck in open position | 2. Repair or replace unloader valve. | ||

pressure switch |

|

|

| Do not disassemble check |

|

|

| ||

|

|

|

| valve with air in tank; |

|

|

|

| |

|

| bleed tank | ||

|

|

|

|

|

26 Sp | 7 |