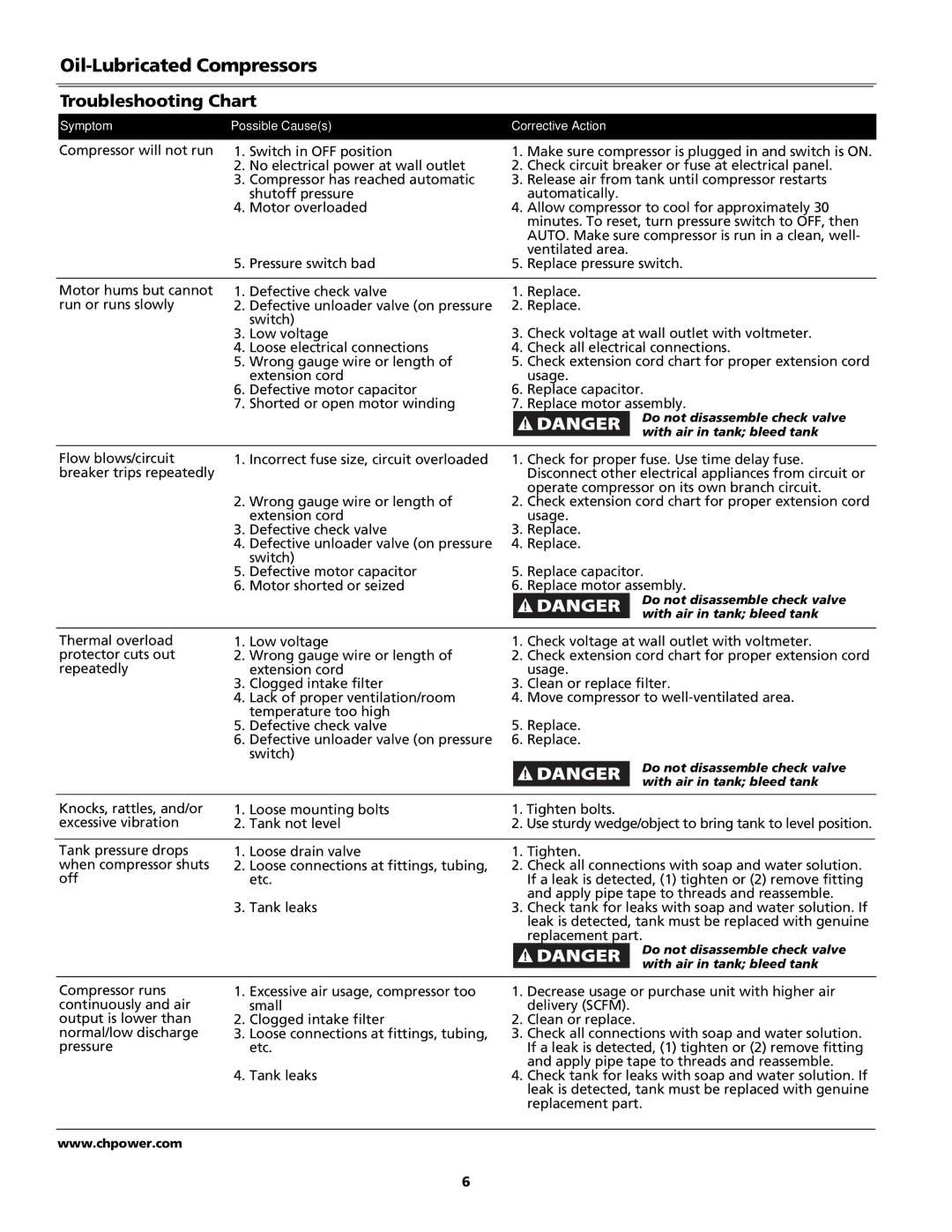

Oil-Lubricated Compressors

Troubleshooting Chart

| Symptom | Possible Cause(s) | Corrective Action | ||||

|

|

|

|

|

|

| |

| Compressor will not run | 1. Switch in OFF position | 1. | Make sure compressor is plugged in and switch is ON. | |||

|

| 2. | No electrical power at wall outlet | 2. | Check circuit breaker or fuse at electrical panel. | ||

|

| 3. | Compressor has reached automatic | 3. | Release air from tank until compressor restarts | ||

|

|

| shutoff pressure |

|

| automatically. | |

|

| 4. | Motor overloaded | 4. | Allow compressor to cool for approximately 30 | ||

|

|

|

|

|

| minutes. To reset, turn pressure switch to OFF, then | |

|

|

|

|

|

| AUTO. Make sure compressor is run in a clean, well- | |

|

|

|

|

|

| ventilated area. | |

|

| 5. | Pressure switch bad | 5. | Replace pressure switch. | ||

|

|

|

|

| |||

| Motor hums but cannot | 1. Defective check valve | 1. | Replace. | |||

| run or runs slowly | 2. Defective unloader valve (on pressure | 2. | Replace. | |||

|

|

| switch) | 3. | Check voltage at wall outlet with voltmeter. | ||

|

| 3. | Low voltage | ||||

|

| 4. | Loose electrical connections | 4. | Check all electrical connections. | ||

|

| 5. | Wrong gauge wire or length of | 5. | Check extension cord chart for proper extension cord | ||

|

|

| extension cord |

|

| usage. | |

|

| 6. | Defective motor capacitor | 6. | Replace capacitor. | ||

|

| 7. | Shorted or open motor winding | 7. | Replace motor assembly. | ||

|

|

|

|

|

|

| Do not disassemble check valve |

|

|

|

|

|

|

| with air in tank; bleed tank |

|

|

|

|

|

|

| |

Flow blows/circuit breaker trips repeatedly

1. | Incorrect fuse size, circuit overloaded | 1. | Check for proper fuse. Use time delay fuse. | ||

|

|

|

| Disconnect other electrical appliances from circuit or | |

|

|

|

| operate compressor on its own branch circuit. | |

2. | Wrong gauge wire or length of | 2. | Check extension cord chart for proper extension cord | ||

| extension cord |

|

| usage. | |

3. | Defective check valve | 3. | Replace. | ||

4. | Defective unloader valve (on pressure | 4. | Replace. | ||

| switch) | 5. | Replace capacitor. | ||

5. | Defective motor capacitor | ||||

6. | Motor shorted or seized | 6. | Replace motor assembly. | ||

|

|

|

|

| Do not disassemble check valve |

|

|

|

|

| with air in tank; bleed tank |

|

|

|

|

| |

Thermal overload protector cuts out repeatedly

1. | Low voltage | 1. | Check voltage at wall outlet with voltmeter. | ||

2. | Wrong gauge wire or length of | 2. | Check extension cord chart for proper extension cord | ||

| extension cord |

|

| usage. | |

3. | Clogged intake filter | 3. | Clean or replace filter. | ||

4. | Lack of proper ventilation/room | 4. | Move compressor to | ||

| temperature too high | 5. | Replace. | ||

5. | Defective check valve | ||||

6. | Defective unloader valve (on pressure | 6. | Replace. | ||

| switch) |

|

|

| Do not disassemble check valve |

|

|

|

|

| |

|

|

|

|

| with air in tank; bleed tank |

|

|

|

|

| |

Knocks, rattles, and/or | 1. | Loose mounting bolts | 1. Tighten bolts. | |||

excessive vibration | 2. | Tank not level | 2. Use sturdy wedge/object to bring tank to level position. | |||

|

|

|

|

| ||

Tank pressure drops | 1. | Loose drain valve | 1. | Tighten. | ||

when compressor shuts | 2. | Loose connections at fittings, tubing, | 2. | Check all connections with soap and water solution. | ||

off |

| etc. |

|

| If a leak is detected, (1) tighten or (2) remove fitting | |

|

|

|

|

| and apply pipe tape to threads and reassemble. | |

| 3. | Tank leaks | 3. | Check tank for leaks with soap and water solution. If | ||

|

|

|

|

| leak is detected, tank must be replaced with genuine | |

|

|

|

|

| replacement part. | |

|

|

|

|

|

| Do not disassemble check valve |

|

|

|

|

|

| with air in tank; bleed tank |

|

|

|

|

|

| |

Compressor runs continuously and air output is lower than normal/low discharge pressure

1. | Excessive air usage, compressor too | 1. | Decrease usage or purchase unit with higher air |

| small |

| delivery (SCFM). |

2. | Clogged intake filter | 2. | Clean or replace. |

3. | Loose connections at fittings, tubing, | 3. | Check all connections with soap and water solution. |

| etc. |

| If a leak is detected, (1) tighten or (2) remove fitting |

|

|

| and apply pipe tape to threads and reassemble. |

4. | Tank leaks | 4. | Check tank for leaks with soap and water solution. If |

|

|

| leak is detected, tank must be replaced with genuine |

|

|

| replacement part. |

www.chpower.com

6