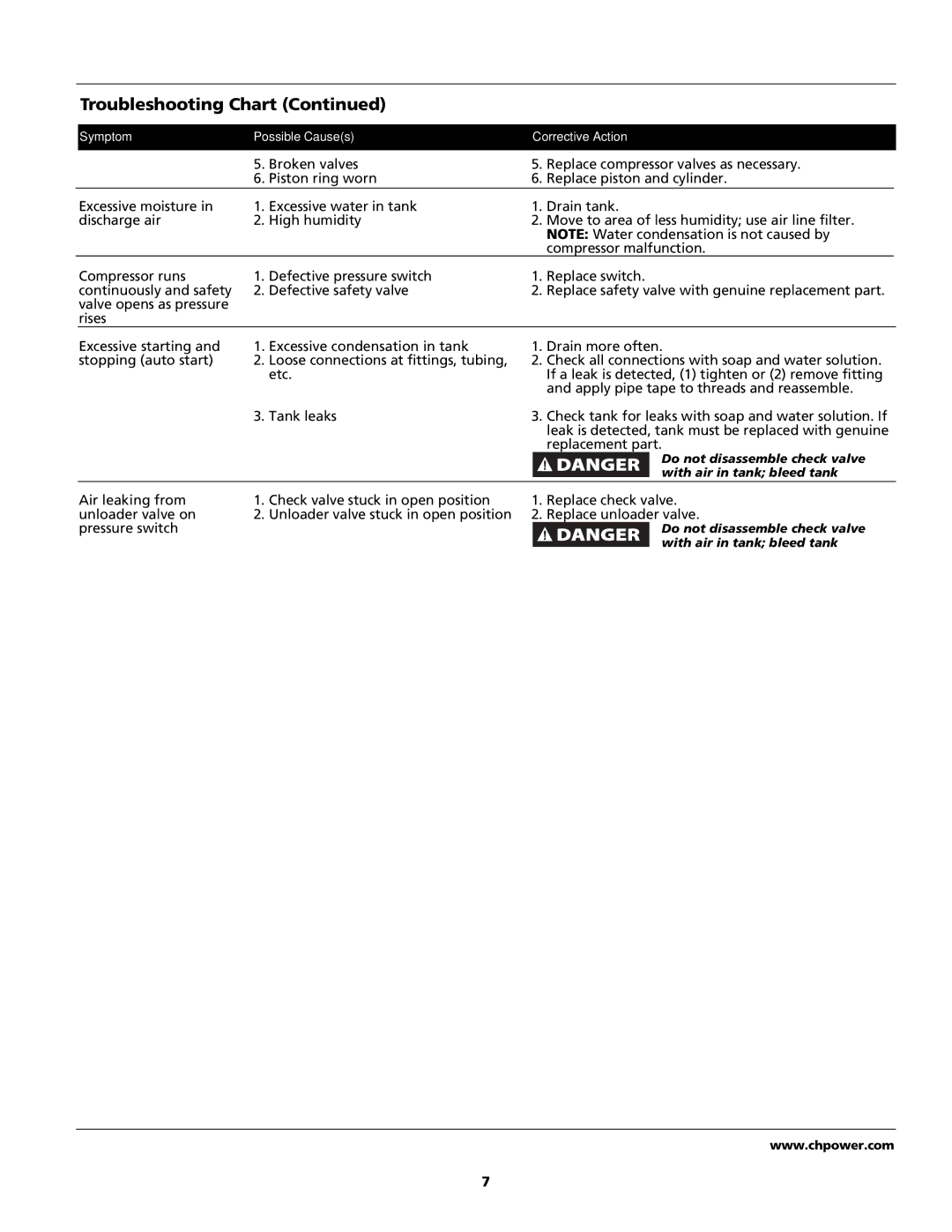

Troubleshooting Chart (Continued)

| Symptom | Possible Cause(s) |

| Corrective Action |

| |||

|

|

|

|

|

|

|

|

|

|

| 5. | Broken valves | 5. | Replace compressor valves as necessary. |

| ||

|

| 6. | Piston ring worn | 6. | Replace piston and cylinder. |

| ||

| Excessive moisture in | 1. | Excessive water in tank | 1. | Drain tank. |

| ||

| discharge air | 2. | High humidity | 2. | Move to area of less humidity; use air line filter. |

| ||

|

|

|

|

|

| NOTE: Water condensation is not caused by |

| |

|

|

|

|

|

| compressor malfunction. |

| |

| Compressor runs | 1. | Defective pressure switch | 1. | Replace switch. |

| ||

| continuously and safety | 2. | Defective safety valve | 2. | Replace safety valve with genuine replacement part. |

| ||

| valve opens as pressure |

|

|

|

|

|

|

|

| rises |

|

|

|

|

|

|

|

| Excessive starting and | 1. | Excessive condensation in tank | 1. | Drain more often. |

| ||

| stopping (auto start) | 2. | Loose connections at fittings, tubing, | 2. | Check all connections with soap and water solution. |

| ||

|

|

| etc. |

|

| If a leak is detected, (1) tighten or (2) remove fitting |

| |

|

|

|

|

|

| and apply pipe tape to threads and reassemble. |

| |

|

| 3. | Tank leaks | 3. | Check tank for leaks with soap and water solution. If |

| ||

|

|

|

|

|

| leak is detected, tank must be replaced with genuine |

| |

|

|

|

|

|

| replacement part. |

| |

|

|

|

|

|

|

| Do not disassemble check valve |

|

|

|

|

|

|

|

| with air in tank; bleed tank |

|

|

|

|

|

|

|

|

| |

| Air leaking from | 1. | Check valve stuck in open position | 1. | Replace check valve. |

| ||

| unloader valve on | 2. | Unloader valve stuck in open position | 2. | Replace unloader valve. |

| ||

| pressure switch |

|

|

|

|

| Do not disassemble check valve |

|

|

|

|

|

|

|

| with air in tank; bleed tank |

|

|

|

|

|

|

|

|

| |

www.chpower.com

7