Operating Instructions | Model SN258K |

General Safety Information (Continued)

labels are located on the tool maga- zine and body.

●Do not drop or throw the tool. Dropping or throwing the tool can result in damage that will make the tool unusable or unsafe. If the tool has been dropped or thrown, exam- ine the tool closely for bent, cracked or broken parts and air leaks. STOP and repair before using or serious injury could occur.

Caution indicates ! CAUTION a potentially haz-

ardous situation which, if not avoided, MAY result in minor or moderate injury.

●Do not make any modifications to the tool without first obtaining written approval from Campbell Hausfeld. Do not use the tool if any shields or guards are removed or altered. Do not use the tool as a hammer. Personal injury or tool

damage may occur.

●Always check that the Work

Contact Element (WCE) is operat-

ing properly. A fastener could

accidentally be driven if the WCE is not

working properly. Personal injury may occur (See "Checking the Work Contact Element" Section).

●Disconnect air supply and release tension from the pusher before attempting to clear jams because tools can be ejected from the front of the tool. Personal injury may occur.

NOTICE | Notice indicates |

important infor- |

mation, that if not followed, MAY cause damage to equipment.

●Avoid using the tool when the mag- azine is empty. Accelerated wear on the tool may occur.

●Clean and check all air supply hoses and fittings before connecting the tool to an air supply. Replace any damaged or worn hoses or fittings. Tool performance or durability may be reduced.

●Air compressors providing air to the tool should follow the requirements established by the American National Standards Institute Standard

Operating The

Stapler

Read this manual and understand all safety warnings and instruc- tions before operating the stapler.

LUBRICATION

This stapler requires lubrication before using the stapler for the first time and before each use. If an inline oiler is used, manual lubrication through the air inlet is not required on a daily basis.

NOTICE | The work surface | |

can become dam- | ||

|

aged by excessive lubrication. Proper lubrication is the owner’s responsibility. Failure to lubricate the stapler properly will dramatically shorten the life of the stapler and void your warranty.

1. Disconnect the

air supply from the stapler to

add lubricant.

2. Turn the sta- pler so the air

inlet is facing up. Place

30 W |

|

|

|

|

|

gent oil into air | OIL | ||||

inlet. Do not use |

|

|

|

|

|

detergent oils, oil |

|

|

|

|

|

additives, or air tool |

|

|

|

|

|

oils. Air tool oils |

|

|

|

|

|

contain solvents |

|

|

|

|

|

which will damage |

|

|

|

|

|

the stapler's internal components.

3. After adding oil, run stapler briefly. Wipe off any excess oil from the cap exhaust.

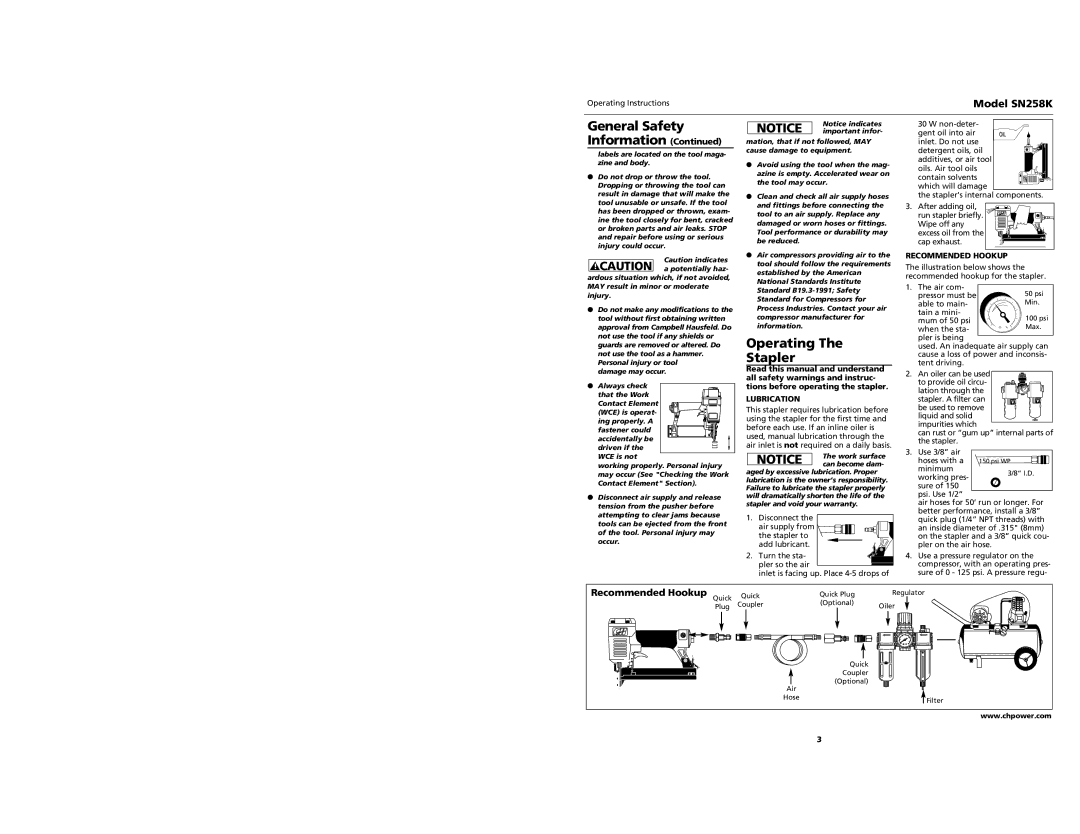

RECOMMENDED HOOKUP

The illustration below shows the recommended hookup for the stapler.

1. The air com- pressor must be able to main-

tain a mini- mum of 50 psi

when the sta- pler is being

used. An inadequate air supply can cause a loss of power and inconsis- tent driving.

2. An oiler can be used ![]()

to provide oil circu- lation through the stapler. A filter can be used to remove liquid and solid impurities which

can rust or “gum up” internal parts of the stapler.

3. Use 3/8” air

hoses with a minimum

working pres- sure of 150 psi. Use 1/2”

air hoses for 50’ run or longer. For better performance, install a 3/8” quick plug (1/4” NPT threads) with an inside diameter of .315" (8mm) on the stapler and a 3/8” quick cou- pler on the air hose.

4.Use a pressure regulator on the compressor, with an operating pres- sure of 0 - 125 psi. A pressure regu-

Recommended Hookup | Quick | Quick | Quick Plug | Regulator |

| Coupler | (Optional) | Oiler | |

| Plug | |||

|

|

| Quick |

|

|

|

| Coupler |

|

|

|

| (Optional) |

|

|

|

| Air |

|

|

|

| Hose | Filter |

|

|

|

| |

|

|

|

| www.chpower.com |

|

|

| 3 |

|