Operating Instructions | Model SN258K |

Technical Support

Please call our Tool Hotline at

Fastener And Replacement Parts

Use only

! WARNING genuine Campbell Hausfeld 18 gauge fasteners (or equiva- lent - see Fastener Interchange

Information). Tool performance, safety and durability could be reduced if improper fasteners are used. When ordering replacement parts or fasten- ers, specify by part number.

Tool Repair

Only qualified personnel should repair the tool, and they should use genuine Campbell Hausfeld replacement parts and accessories, or parts and accessories which perform equivalently.

Assembly Procedure For Seals

When repairing a stapler, the internal parts must be cleaned and lubricated. Parker

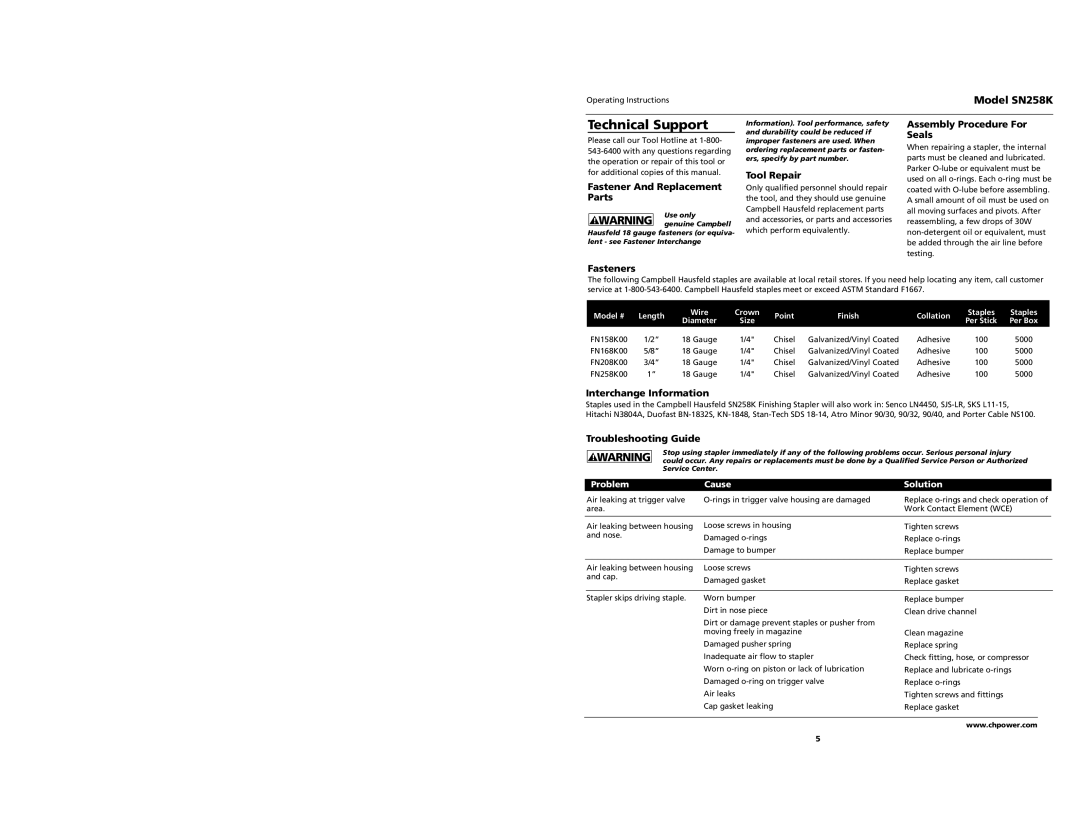

Fasteners

The following Campbell Hausfeld staples are available at local retail stores. If you need help locating any item, call customer service at

Model # | Length | Wire | Crown | Point | Finish | Collation | Staples | Staples | |

Diameter | Size | Per Stick | Per Box | ||||||

|

|

|

|

| |||||

FN158K00 | 1/2” | 18 Gauge | 1/4" | Chisel | Galvanized/Vinyl Coated | Adhesive | 100 | 5000 | |

FN168K00 | 5/8” | 18 Gauge | 1/4" | Chisel | Galvanized/Vinyl Coated | Adhesive | 100 | 5000 | |

FN208K00 | 3/4” | 18 Gauge | 1/4" | Chisel | Galvanized/Vinyl Coated | Adhesive | 100 | 5000 | |

FN258K00 | 1” | 18 Gauge | 1/4" | Chisel | Galvanized/Vinyl Coated | Adhesive | 100 | 5000 |

Interchange Information

Staples used in the Campbell Hausfeld SN258K Finishing Stapler will also work in: Senco LN4450,

Troubleshooting Guide

!WARNING

Stop using stapler immediately if any of the following problems occur. Serious personal injury could occur. Any repairs or replacements must be done by a Qualified Service Person or Authorized Service Center.

| Problem | Cause | Solution |

| |

| Air leaking at trigger valve | Replace |

| ||

| area. |

| Work Contact Element (WCE) |

| |

|

|

|

|

|

|

| Air leaking between housing | Loose screws in housing | Tighten screws |

| |

| and nose. | Damaged | Replace |

| |

|

|

| |||

|

| Damage to bumper | Replace bumper |

| |

|

|

|

|

|

|

| Air leaking between housing | Loose screws | Tighten screws |

| |

| and cap. | Damaged gasket | Replace gasket |

| |

|

|

| |||

|

|

|

|

|

|

| Stapler skips driving staple. | Worn bumper | Replace bumper |

| |

|

| Dirt in nose piece | Clean drive channel |

| |

|

| Dirt or damage prevent staples or pusher from |

|

|

|

|

| moving freely in magazine | Clean magazine |

| |

|

| Damaged pusher spring | Replace spring |

| |

|

| Inadequate air flow to stapler | Check fitting, hose, or compressor |

| |

|

| Worn | Replace and lubricate |

| |

|

| Damaged | Replace |

| |

|

| Air leaks | Tighten screws and fittings |

| |

|

| Cap gasket leaking | Replace gasket |

| |

|

|

|

|

|

|

|

|

| www.chpower.com |

| |

5