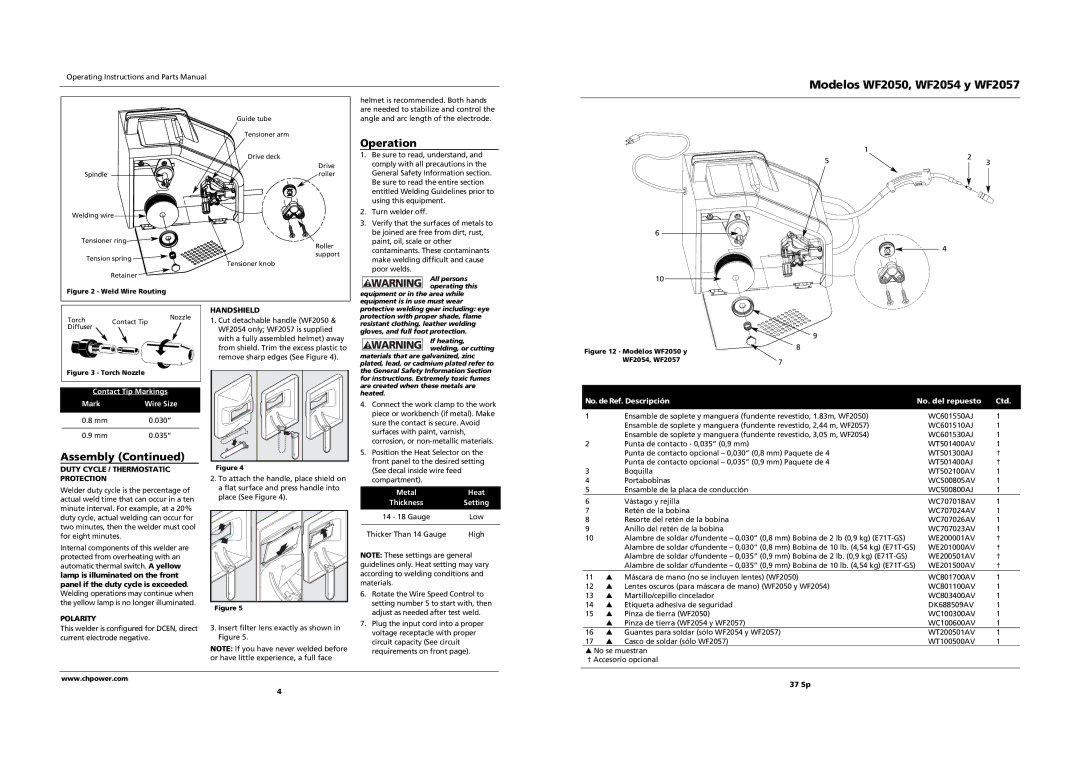

WF2050, WF2054, WF2057 specifications

The Campbell Hausfeld line of air compressors includes several models such as WF2057, WF2054, WF2058, and WF2050, each designed to meet the needs of both amateur and professional users. These models are known for their durability, efficiency, and versatility, making them ideal for a variety of tasks ranging from inflation to powering pneumatic tools.The WF2057 air compressor is popular for its compact design and portability, boasting a lightweight frame that allows for easy transport. It features a powerful 3-gallon tank, which provides sufficient air supply for small tasks such as inflating tires and powering nail guns. The oil-free pump technology ensures hassle-free maintenance while also extending the compressor’s lifespan. Users appreciate the quick-connect air hose fitting, which provides ease of access and minimizes downtime during projects.

In contrast, the WF2054 model is tailored for those who require a slightly higher output. With a 4-gallon tank, this compressor offers increased air capacity, allowing it to handle a greater range of tools and applications. The low noise operation is a significant selling point, enabling use in residential areas without disturbing the peace. Additionally, its built-in regulator makes adjusting the pressure settings simple, ensuring that it is compatible with a range of pneumatic tools.

The WF2058 model stands out with its dual-purpose functionality. It can be operated as a direct drive compressor, or in a conventional manner, giving users flexibility based on their specific needs. This model also incorporates a robust safety design with an automatic thermal overload protection feature. This not only protects the unit from overheating but also prolongs its operational life.

Lastly, the WF2050 round out this series by offering enhanced power and efficiency. This model is equipped with a larger tank capacity, ideal for continuous use applications. The quick recovery time ensures that users can work without lengthy interruptions, making it suitable for more demanding tasks. The integrated pressure gauges and controls improve usability, enabling users to monitor and adjust settings easily.

Overall, the Campbell Hausfeld WF2057, WF2054, WF2058, and WF2050 models showcase the brand's commitment to quality and performance. These compressors are designed with the user in mind, featuring a combination of innovative technologies and user-friendly interfaces. Whether you are a DIY enthusiast or a professional contractor, these models provide the reliability and efficiency needed for a wide range of air-powered tasks.